Method for controlling optimized burning in circulating fluid bed boiler

A circulating fluidized bed and boiler combustion technology, which is applied to fluidized bed combustion equipment, combustion methods, and fuels burned in a molten state, can solve the problems of affecting the fluidization state of the bed material, overshoot, and narrow adjustment range. The effect of solving the difficulty of coordinated control, obvious control effect and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

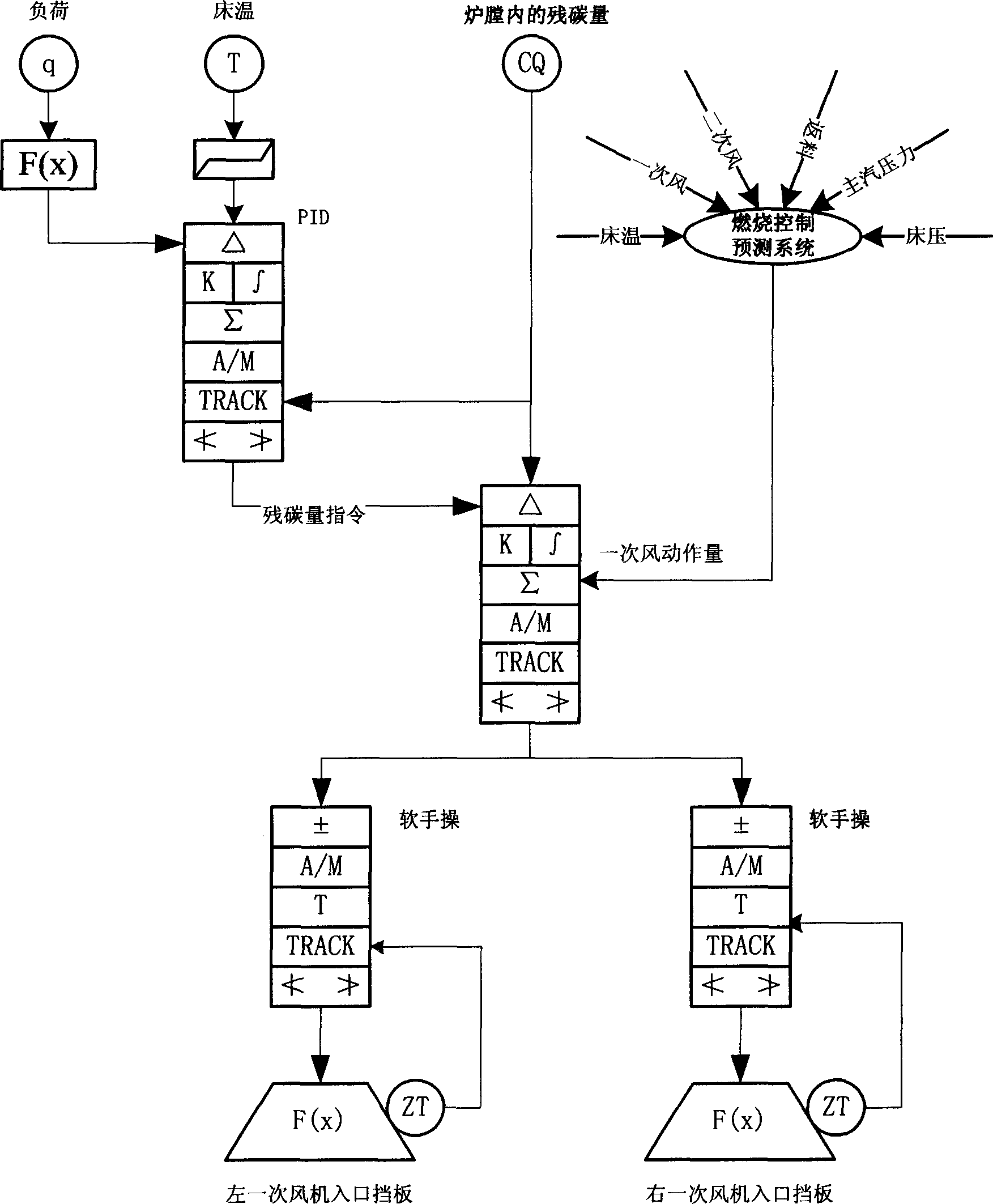

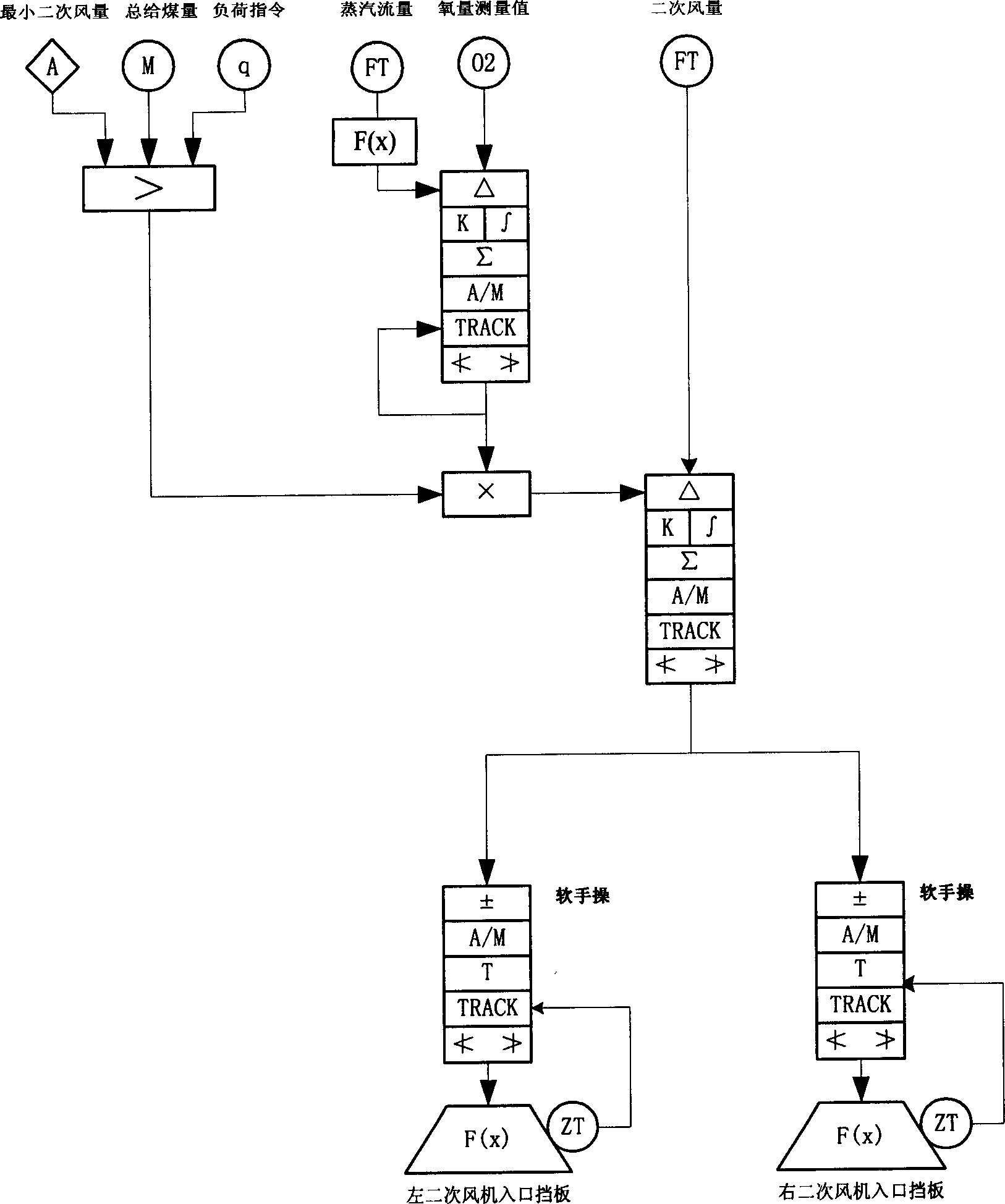

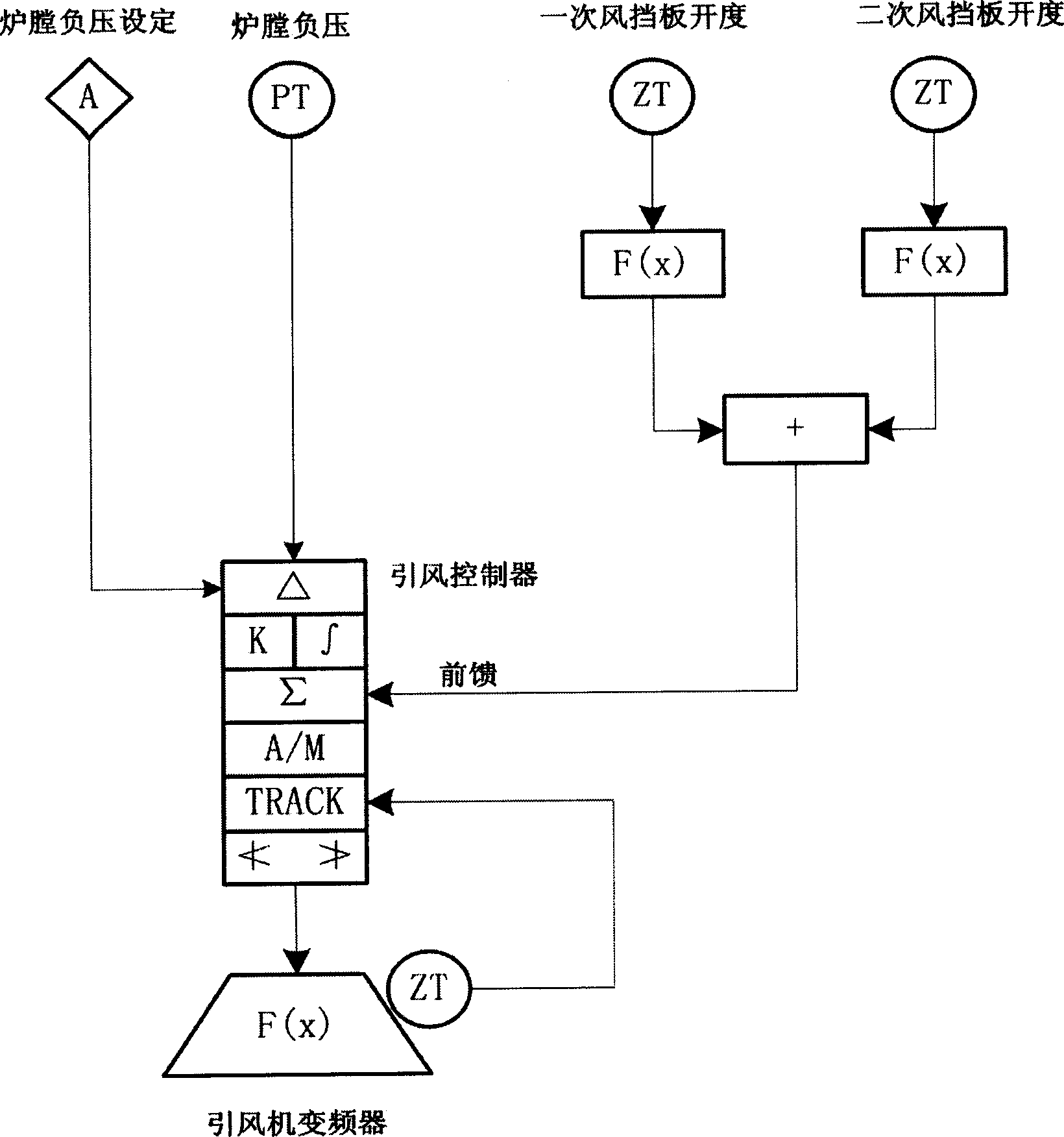

[0051] The present invention will be further described below by taking a 440t / h circulating fluidized bed (CFB) boiler as an example. This example is developed on the platform of distributed control system (DCS), including the following steps:

[0052] A) Coordinated control of machine and furnace:

[0053] The design of the coordinated control system considers the adjustment, interlocking, protection, alarm and monitoring management, and controls the boiler and steam turbine as a whole.

[0054] In the coordinated control system mode, it can accept the 4-20mA ADS signal transferred from the power grid, and participate in the AGC operation of the power grid at a certain rate (3% rated load / min) within the range of the boiler's stable combustion load.

[0055] As a whole, the boiler steam turbine is coordinated and controlled, and the principle of direct energy (DEB) balance control is adopted to ensure the stable operation of the pressure before the machine. According to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com