Compact parallel connection type external fluidized bed heat exchanger

A technology of fluidized bed heat exchanger and circulating fluidized bed, which is applied to fluidized bed combustion equipment, combustion type, lighting and heating equipment, etc. Solve problems such as temperature fluctuations, achieve the effects of strengthening the heat transfer process, improving heat exchange capacity and heat exchange efficiency, improving the uniformity of returning materials and the fluctuation of bed temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

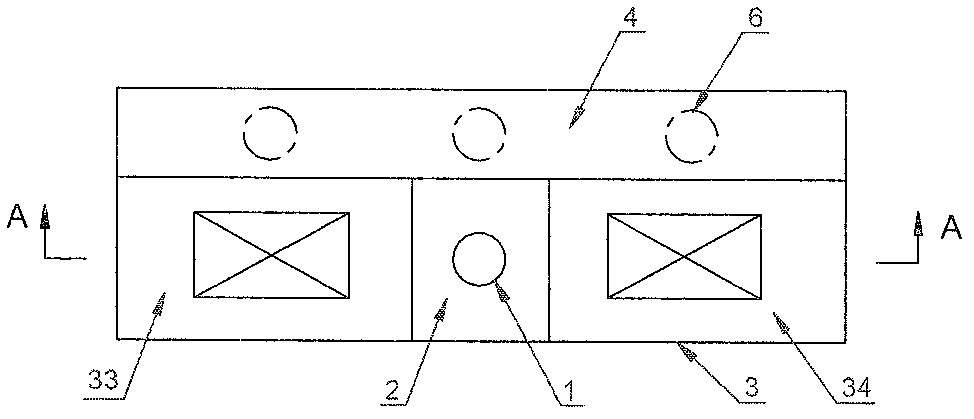

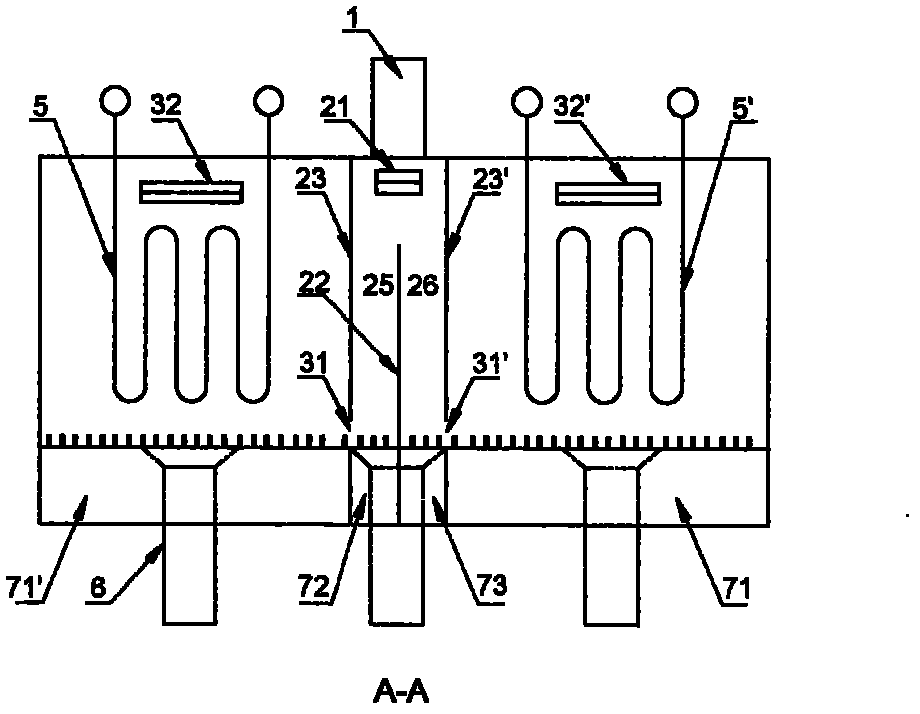

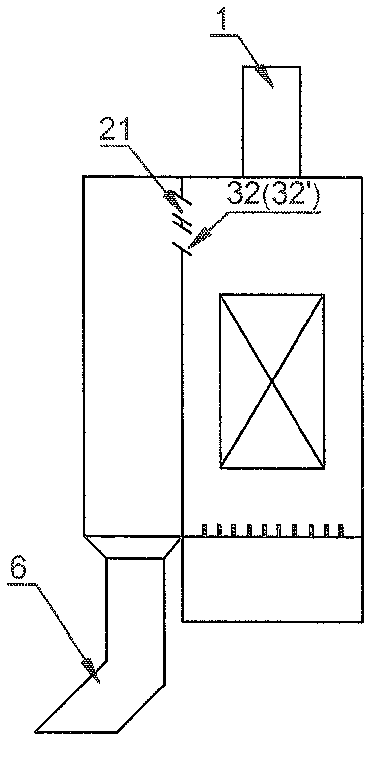

[0039] refer to Figure 1 to Figure 3 , a compact parallel external fluidized bed heat exchanger provided by the present invention includes a feed inlet 1 , a material distributor 2 , a heat exchanger 3 , a feed return chamber 4 and a feed return port 6 . The upper end of the feed port 1 is connected to the solid outlet of the cyclone separator, and the lower end is connected to the material distributor 2. The material distributor 2 is divided into a first feeding chamber 25 and a second feeding chamber 26 through a partition 22. The first feeding chamber The feed chamber 25 communicates with the second feed chamber 26 through the through hole at the top of the partition 22, the first feed chamber 25 communicates with the first heat exchange chamber 33 through the through hole 31 at the bottom of the partition 23, and the second feed chamber 26 communicates with the second heat exchange chamber 34 through the through hole 31' at the bottom of the partition 23', and the materia...

Embodiment 2

[0042] refer to Figure 5 to Figure 8 , a compact parallel external fluidized bed heat exchanger provided by the present invention includes a feed inlet 1 , a material distributor 201 , a material conveyor 202 , a heat exchanger 3 , a material return chamber 4 and a material return port 6 . The upper end of the feed port 1 is connected to the solid outlet of the cyclone separator, and the lower end is connected to the material distributor 201. The material distributor 201 is divided into a first feeding chamber 25 and a second feeding chamber 26 through a partition 22. The first feeding chamber The feed chamber 25 communicates with the second feed chamber 26 through the through hole at the top of the partition plate 22, the first feed chamber 25 communicates with the first return passage 27 through the through hole 24 at the top of the partition plate 23, and the second feed chamber 26 The through hole 24' on the top of the partition plate 23' communicates with the second retu...

Embodiment 3

[0045] refer to Figure 9 to Figure 11 , a compact parallel external fluidized bed heat exchanger provided by the present invention includes a feed inlet 1 , a material distributor 2 , a heat exchanger 3 , a feed return chamber 4 and a feed return port 6 . The upper end of the feed port 1 communicates with the solid outlet of the cyclone separator, and the lower end communicates with the material distributor 2. The material distributor 2 is divided into a first feeding chamber 25 and a second feeding chamber 26 through a partition 22. The first feeding chamber 25 communicates with the second feeding chamber 26 through the top through hole of the partition 22, and the material distributor 2 communicates with the return chamber 4 through the upper through hole 21, and the lowest point of the through hole 21 is higher than the upper surface of the partition 22. The heat exchanger 3 includes a first heat exchange chamber 33 and a second heat exchange chamber 34. The first heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com