Preparation process of dense soda ash

A technology of heavy soda ash and preparation process, which is applied in the direction of changing the content of crystallization water by alkali metal carbonate, can solve the problems of cumbersome operation, complicated process and high investment cost of heavy soda ash production, and achieves simple process steps and reduced investment cost. , the effect of reducing the investment of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

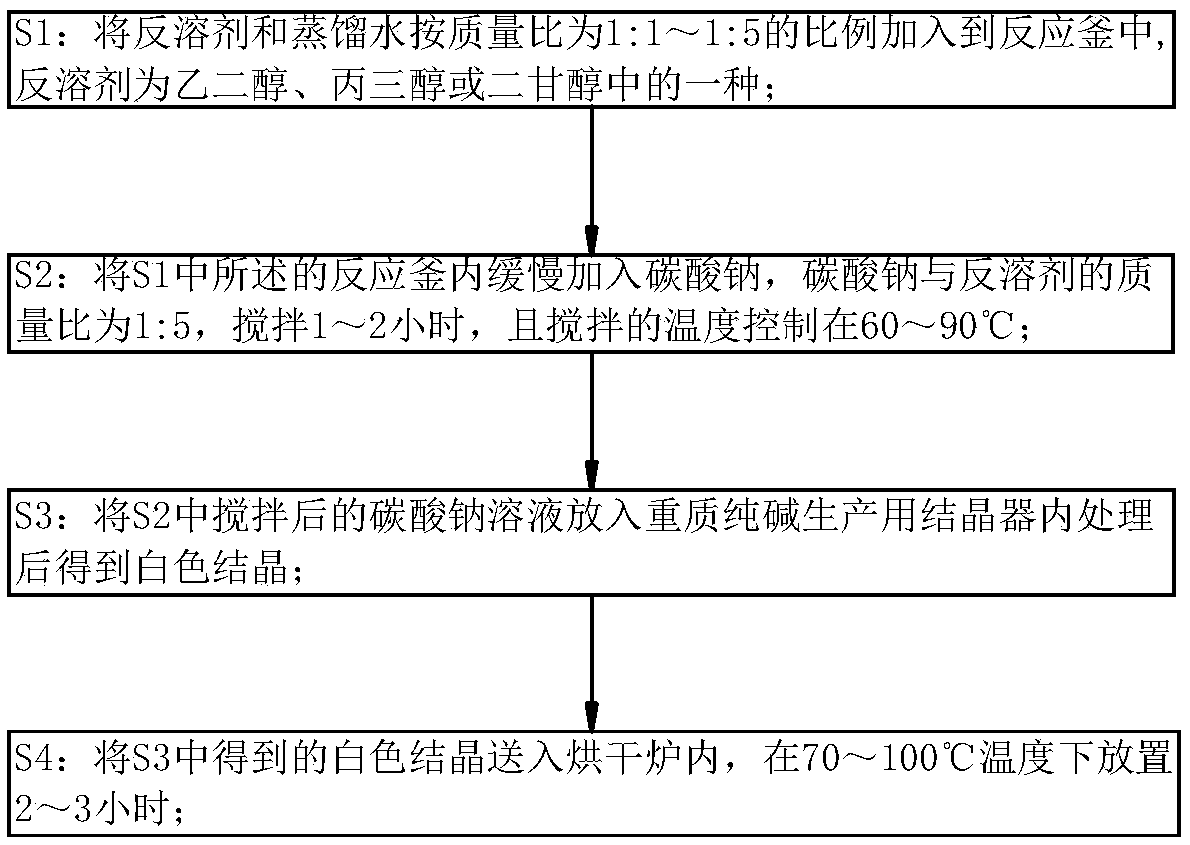

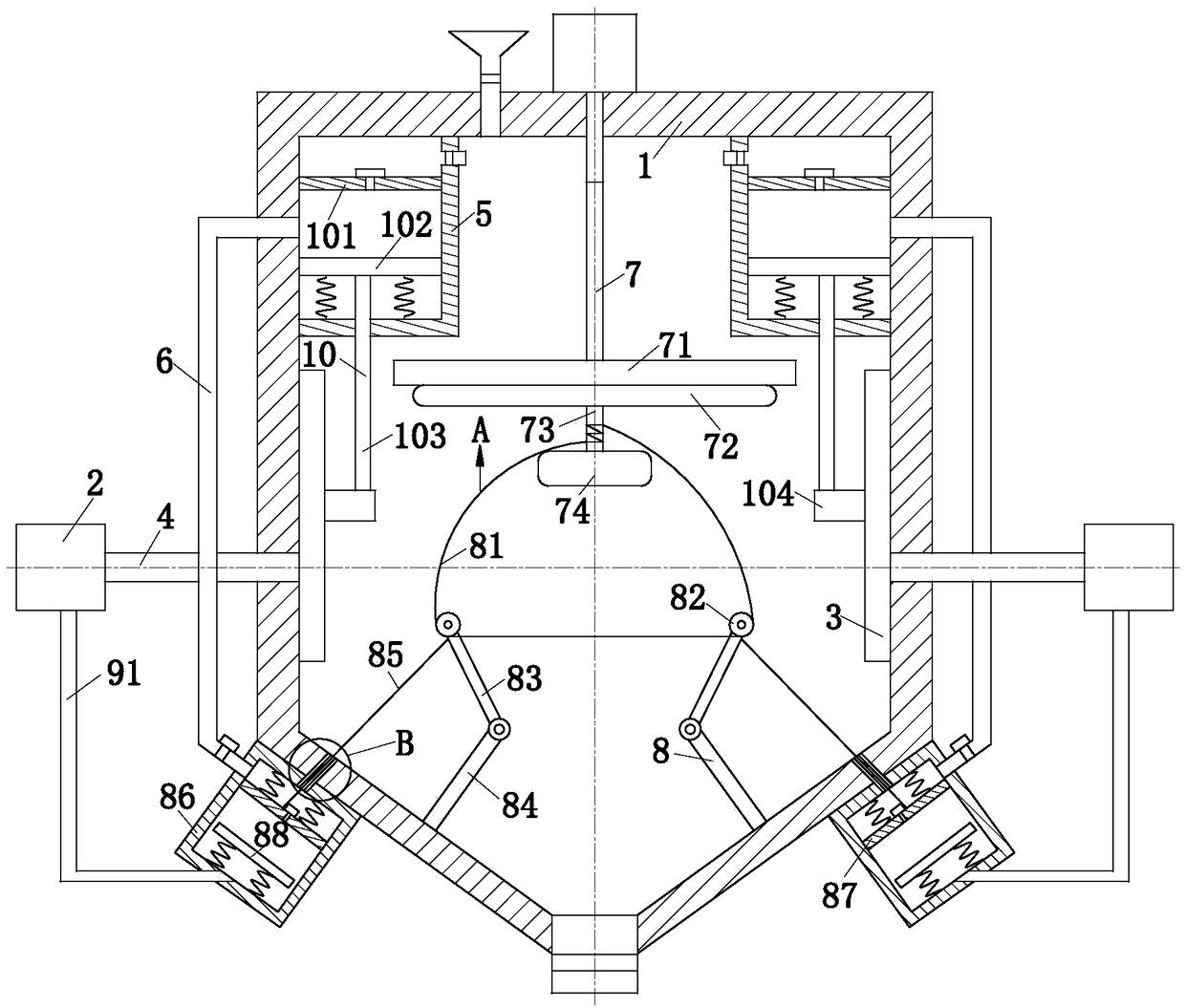

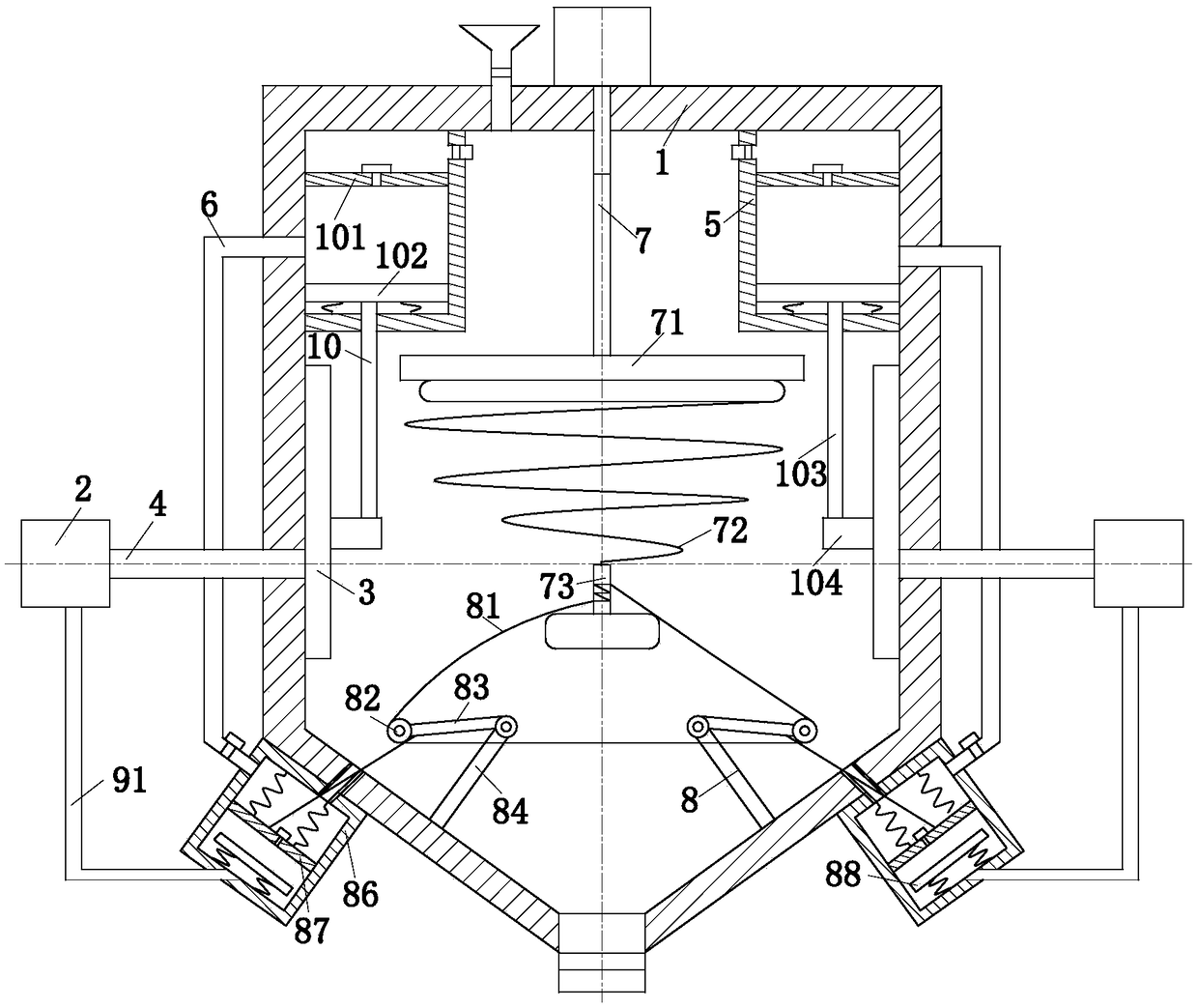

[0029] Such as Figure 1 to Figure 5 Shown, a kind of heavy soda ash preparation technique of the present invention, this technique comprises the following steps:

[0030] S1: Add anti-solvent and distilled water into the reaction kettle at a mass ratio of 1:1 to 1:5, and the anti-solvent is one of ethylene glycol, glycerol or diethylene glycol; the anti-solvent can increase carbon The rate at which sodium crystallizes;

[0031] S2: Slowly add sodium carbonate into the reaction kettle described in S1, the mass ratio of sodium carbonate to anti-solvent is 1:5, stir for 1-2 hours, and control the stirring temperature at 60-90°C; the purpose of stirring is Accelerate the dissolution rate of sodium carbonate, and the purpose of controlling the stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com