Method for preparing magnesium chloride and application of magnesium chloride prepared through method

A technology of magnesium chloride and anhydrous magnesium chloride, applied in the preparation/separation of magnesium chloride and ammonia, chemical instruments and methods, etc., to achieve the effects of simple process, reduced environmental protection pressure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

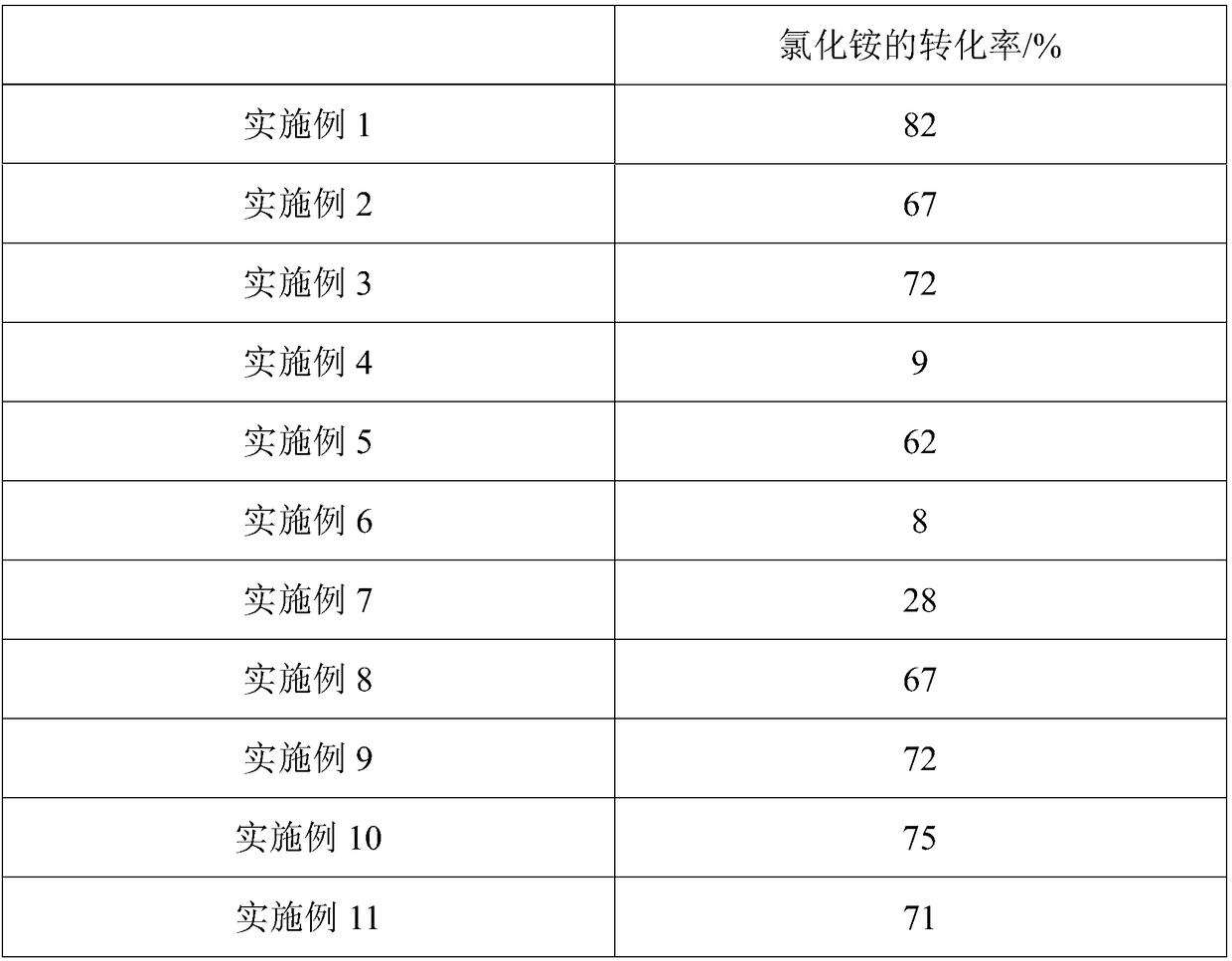

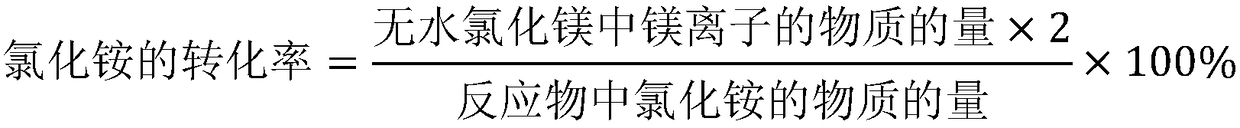

Embodiment 1

[0045] The present embodiment provides a kind of preparation method of magnesium chloride, and described preparation method comprises the steps:

[0046] (1) mix ammonium chloride and magnesium carbonate, obtain mixture, the mol ratio of described ammonium chloride and described magnesium carbonate is 2:1.2;

[0047] (2) Preheat the mixture obtained in step (1) to 150° C. in a muffle furnace at a heating rate of 5° C. / min, and keep it warm for 10 minutes;

[0048] (3) Heating the mixture obtained in step (2) to 320° C. at a heating rate of 5° C. / min in a muffle furnace to 320° C., and heat treatment for 90 minutes to obtain anhydrous magnesium chloride, ammonia and carbon dioxide;

[0049] (4) recrystallization step (3) gained anhydrous magnesium chloride, obtains magnesium chloride product.

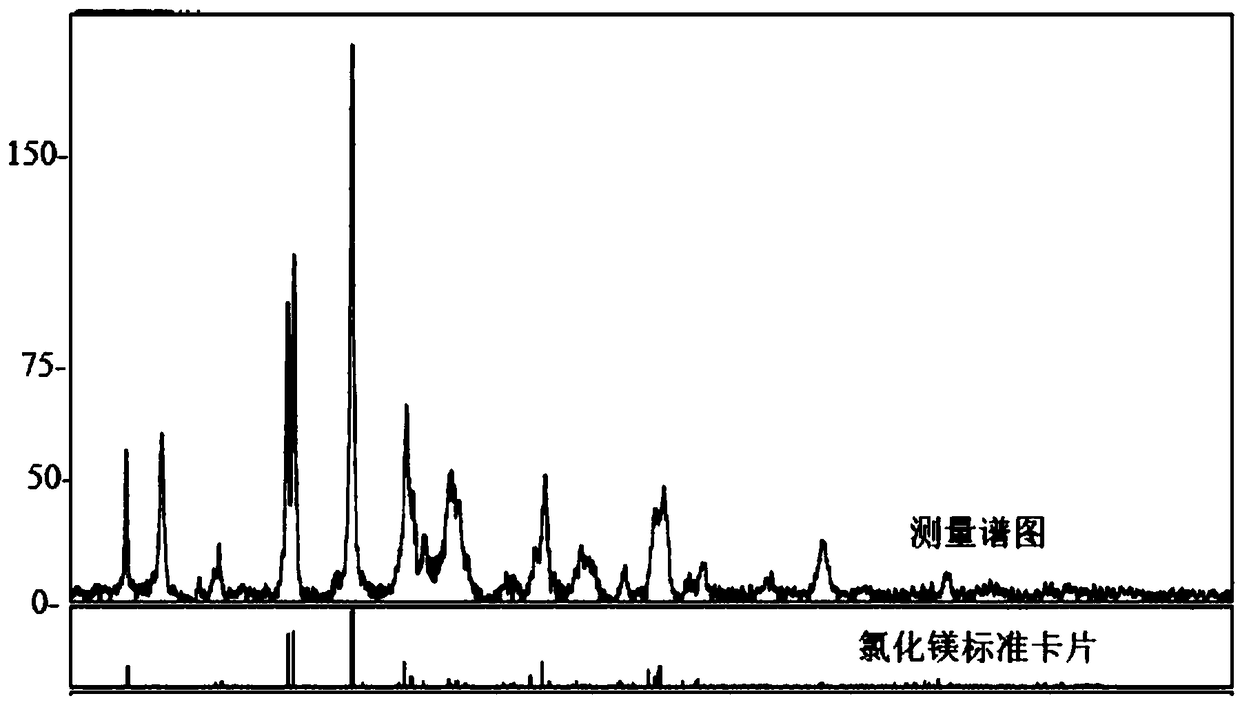

[0050] The XRD spectrum pattern of the anhydrous magnesium chloride that prepares is as figure 1 shown.

Embodiment 2

[0052] The present embodiment provides a kind of preparation method of magnesium chloride, and described preparation method comprises the steps:

[0053] (1) mix ammonium chloride and magnesium carbonate, obtain mixture, the mol ratio of described ammonium chloride and described magnesium carbonate is 2:1;

[0054] (2) Preheat the mixture obtained in step (1) to 140° C. in a muffle furnace at a heating rate of 3° C. / min, and keep it warm for 5 minutes;

[0055] (3) Heating the mixture obtained in step (2) to 240° C. at a heating rate of 4° C. / min in a muffle furnace to 240° C., and heat treatment for 120 minutes to obtain anhydrous magnesium chloride, ammonia and carbon dioxide;

[0056] (4) recrystallization step (3) gained anhydrous magnesium chloride, obtains magnesium chloride product.

Embodiment 3

[0058] The present embodiment provides a kind of preparation method of magnesium chloride, and described preparation method comprises the steps:

[0059] (1) mix ammonium chloride and magnesium carbonate, obtain mixture, the mol ratio of described ammonium chloride and described magnesium carbonate is 2:1.3;

[0060] (2) heating the mixture obtained in step (1) to 350° C. in a muffle furnace at a heating rate of 6° C. / min, and heating for 60 minutes to obtain anhydrous magnesium chloride, ammonia and carbon dioxide;

[0061] (3) recrystallization step (2) gained anhydrous magnesium chloride, obtains magnesium chloride product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com