Method for preparation of concrete admixture from papermaking green mud alkali recovery bottom slag

A technology of concrete and admixture, applied in the field of building materials, can solve the problem of inability to solve a large number of chlorite alkali waste residues, etc., and achieve the effects of strong hydration activity, simple realization, good workability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

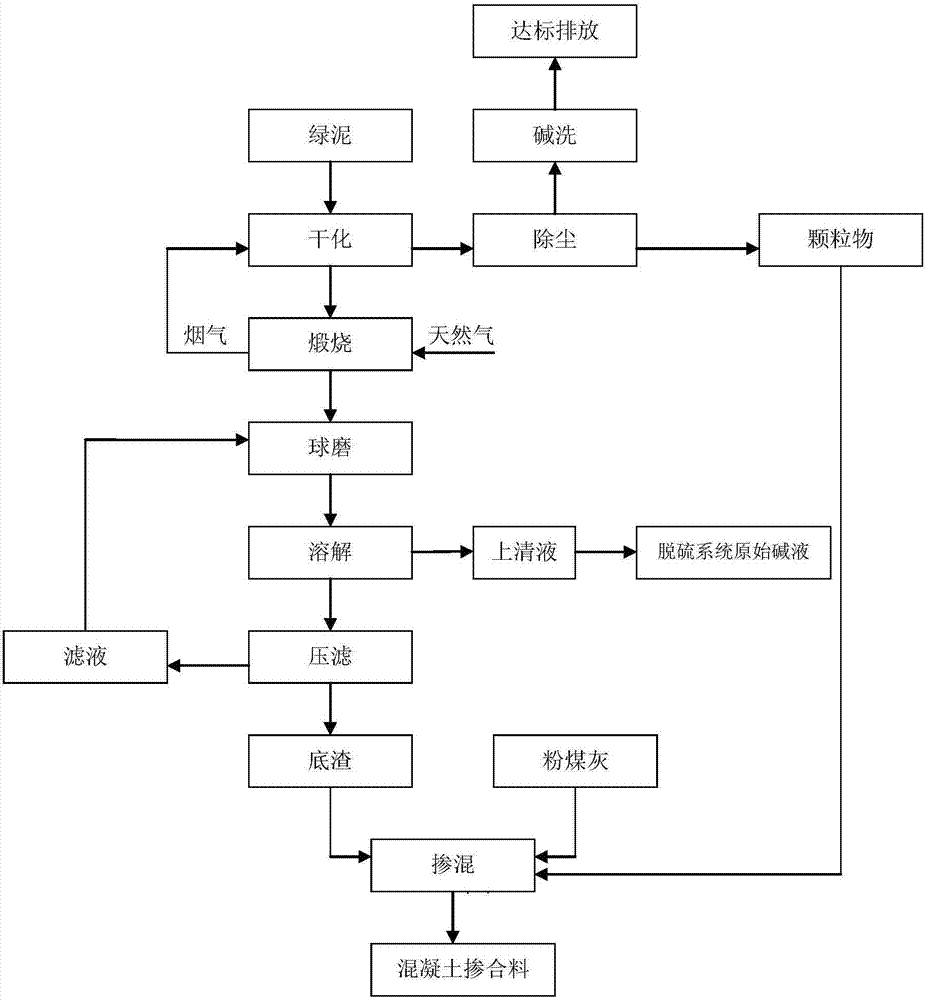

[0021] like figure 1 As shown, this embodiment provides a method for preparing concrete admixture by using papermaking chlorite alkali to recover the bottom slag, and the recovered chlormine alkali can be used as the original lye of the desulfurization system of the coal-fired boiler. specific:

[0022] (1) Drying of papermaking green mud, using calciner flue gas as the heat source, the papermaking green mud is contact-dried to reduce the original moisture content to below 10%, and the flue gas is discharged up to the standard after dust removal and alkali washing. The particles collected by gas dust removal are mixed with green marl and fly ash as concrete admixtures;

[0023] (2) Calcination, at 800-850°C, calcining in a calcination furnace for 10-30min, completely incinerating to remove the organic matter in the green mud, and decomposing the salt in the green mud for papermaking into oxides and converting it into green mud ash. The drying and calcination of papermaking g...

Embodiment 2

[0029] This embodiment provides a method for preparing concrete admixtures by using papermaking chlorite alkali to recover bottom slag, specifically:

[0030] (1) 100 units of paper-making green mud with a moisture content of 40% is used as a heat source, and the rotary kiln drying furnace is used to dry to a moisture content of 10%. The quality of the dried green mud is 66.7 units of mass, and the flue gas is passed through a cyclone After the dust is removed, it will be discharged up to the standard after subsequent treatment, and the dust particles will be collected from the bottom of the cyclone separator for future use.

[0031] (2) 66.7 units of paper-making green mud with a moisture content of 10% is used as fuel by a calcination furnace at 815° C. for 20 minutes to be converted into 40 units of green mud, and the calcined flue gas is used in step (1) green mud Dry.

[0032] (3) Use a ball mill to grind 40 units of green putty to a size below 180 mesh.

[0033] (4) Us...

Embodiment 3

[0040] In this example, the concrete admixture prepared in Example 2 is used to prepare C40 concrete, and the test is carried out according to the method stipulated in the "Concrete Quality Control Standard" (GB50164-2011) to detect the slump and mechanical properties of the concrete. Mixture Performance Test Methods" (GB / T 50080) and "Concrete Strength Inspection and Evaluation Standards" (GB / T50107).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com