Method of cement kiln co-processing for calcium-added and passivated town sludge

A technology of co-processing and cement kiln, which is applied in the direction of water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of serious secondary pollution, multiple fuels, consumption, etc., to avoid landfill, Fuel saving and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

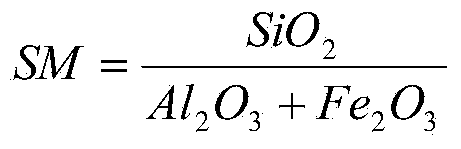

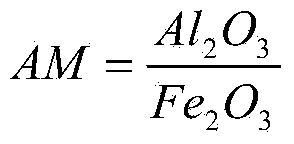

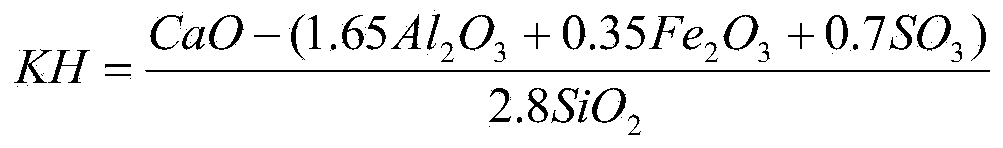

Embodiment 1

[0035] A kind of urban sludge with a moisture content of 78.2%, a volatile matter content of 18.1%, heavy metals Zn, Cu, Cr, and Ni contents of 1046mg / kg, 293mg / kg, 244mg / kg, and 221mg / kg, respectively, Sr, Mn , Ba content are 766mg / kg, 535mg / kg and 386mg / kg respectively. Add 10% (mass percentage) waste lime, transport it to the sludge mixing mixer with a screw conveyor, fully stir it, and stack it naturally for 7 days under direct sunlight. The water content of the mixture of urban sludge and waste lime is 40%. Calculated based on the dry weight of urban sludge and waste lime, mixed with raw meal (see Table 1 for composition) at a replacement ratio of 2%, to meet the SM=2.5, IM=1.5, KH=0.9 of clinker. The clinker calcination method is as follows: the uniform mixture of urban sludge and waste lime is uniformly mixed with cement raw meal, and then pressed with water to form a φ100mm×15mm green sheet. After drying at 105°C for 24 hours, raise the temperature to 1450°C at a rate...

Embodiment 2

[0040] Town sludge properties are the same as in Example 1. Add 15% (mass percentage) waste lime, transport it to the sludge mixing mixer with a screw conveyor, fully stir it, and stack it naturally for 7 days under direct sunlight. The water content of the mixture of urban sludge and waste lime is 38%. Calculated based on the dry weight of urban sludge and waste lime, mixed with raw meal (see Table 1 for composition) at a replacement ratio of 5%, to meet the requirements of SM=2.4, IM=1.5, and KH=0.9 for clinker. The clinker calcining method is the same as in Example 1.

[0041] After the calcined Portland cement clinker is tested, the four main components in the clinker are tricalcium silicate (C 3 S), dicalcium silicate (C 2 S), tricalcium aluminate (C 3 A) and tetracalcium aluminoferrite (C 4 AF) content were 56%, 20%, 7.9% and 9.2%.

[0042] After calcination, the compressive strengths of ordinary Portland cement 1d, 3d and 28d are 11MPa, 22MPa and 54MPa respectively...

Embodiment 3

[0045] Town sludge properties are the same as in Example 1. Add 20% (mass percentage) waste lime, transport it to the sludge mixing mixer with a screw conveyor, fully stir it, and stack it naturally for 7 days under direct sunlight. The water content of the mixture of urban sludge and waste lime is 30%. Calculated based on the dry weight of urban sludge and waste lime, mixed with raw meal (see Table 1 for composition) at a replacement ratio of 10%, to meet the SM=2.5, IM=1.5, KH=0.9 of clinker. The clinker calcining method is the same as in Example 1.

[0046] After the calcined Portland cement clinker is tested, the four main components in the clinker are tricalcium silicate (C 3 S), dicalcium silicate (C 2 S), tricalcium aluminate (C 3 A) and tetracalcium aluminoferrite (C 4 AF) content were 53%, 20%, 8.1% and 9.0%.

[0047] After calcination, the compressive strengths of ordinary Portland cement 1d, 3d and 28d are 10MPa, 21MPa and 51MPa, respectively. Other indicators...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com