Method of cement kiln co-processing for calcium-added and passivated town sludge

A co-processing and cement kiln technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of lack of targeted treatment technology, consumption, serious secondary pollution, etc. Achieve the effect of resource utilization, cost reduction and landfill avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

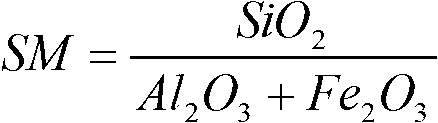

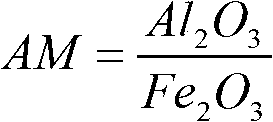

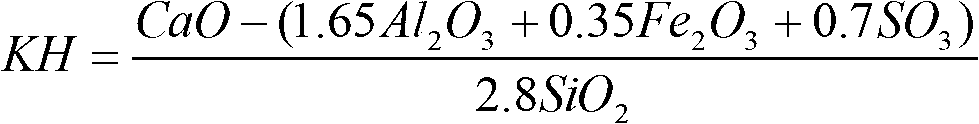

[0036] A kind of urban sludge with a moisture content of 78.2%, a volatile content of 18.1%, and the contents of heavy metals Zn, Cu, Cr, and Ni are 1046mg / kg, 293mg / kg, 244mg / kg and 221mg / kg respectively, Sr, Mn The contents of, Ba are 766mg / kg, 535mg / kg and 386mg / kg respectively. Add 10% (mass percentage) waste lime, use a screw conveyor to transport it to the sludge mixing mixer, fully stir, and pile it naturally for 7 days under direct sunlight. The moisture content of the sludge and waste lime is 40%. Mix with raw meal (see Table 1 for composition) at a replacement ratio of 2% (calculated based on the dry weight of sludge and waste lime) to meet the requirements of SM = 2.5, IM = 1.5, and KH = 0.9 for clinker. The clinker calcination method is as follows: a uniform mixture of sludge and waste lime is uniformly mixed with cement raw material, and water is pressed to form a φ100mm×15mm green sheet. After drying at 105°C for 24 hours, it was heated to 1450°C at a heating rat...

Embodiment 2

[0041] The properties of urban sludge are the same as in Example 1. Add 15% (mass percentage) waste lime, use a screw conveyor to transport it to the sludge mixing mixer for full mixing, and pile it naturally for 7 days under direct sunlight. The moisture content of the sludge and waste lime is 38%. Mix with raw meal (see Table 1 for composition) at a replacement ratio of 5% (calculated based on the dry weight of sludge and waste lime) to meet the SM=2.4, IM=1.5, and KH=0.9 of clinker. The clinker calcination method is the same as in Example 1.

[0042] The Portland cement clinker after calcination is tested. The four main components of the clinker are tricalcium silicate (C 3 S), dicalcium silicate (C 2 S), tricalcium aluminate (C 3 A) and tetracalcium iron aluminate (C 4 The content of AF) was 56%, 20%, 7.9% and 9.2, respectively.

[0043] The 1d, 3d and 28d compressive strengths of the calcined ordinary Portland cement are 11MPa, 22MPa and 54MPa respectively. Other indicators ...

Embodiment 3

[0046] The properties of urban sludge are the same as in Example 1. Add 20% (mass percentage) waste lime, use a screw conveyor to transport to the sludge mixing mixer, fully stir, and pile up naturally for 7 days under direct sunlight. The moisture content of the sludge and waste lime is 30%. Mix with raw meal (see Table 1 for composition) at a replacement ratio of 10% (calculated based on the dry weight of sludge and waste lime) to satisfy the SM=2.5, IM=1.5, and KH=0.9 of the clinker. The clinker calcination method is the same as in Example 1.

[0047] The Portland cement clinker after calcination is tested. The four main components of the clinker are tricalcium silicate (C 3 S), dicalcium silicate (C 2 S), tricalcium aluminate (C 3 A) and tetracalcium iron aluminate (C 4 The content of AF) was 53%, 20%, 8.1% and 9.0, respectively.

[0048] The 1d, 3d and 28d compressive strengths of the calcined ordinary Portland cement are 10MPa, 21MPa and 51MPa respectively. Other indicators...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com