A method for preparing non-sintering cementitious material by using waste incineration fly ash

A technology of waste incineration fly ash and cementitious materials, which is applied in the direction of cement production, etc., to achieve the effects of saving process energy consumption, realizing harmless and resource utilization, and avoiding secondary pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

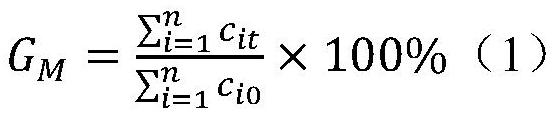

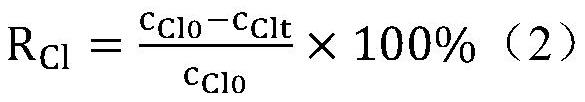

[0022] Effect of mass ratio of graphite powder and waste incineration fly ash on the performance of prepared cementitious materials

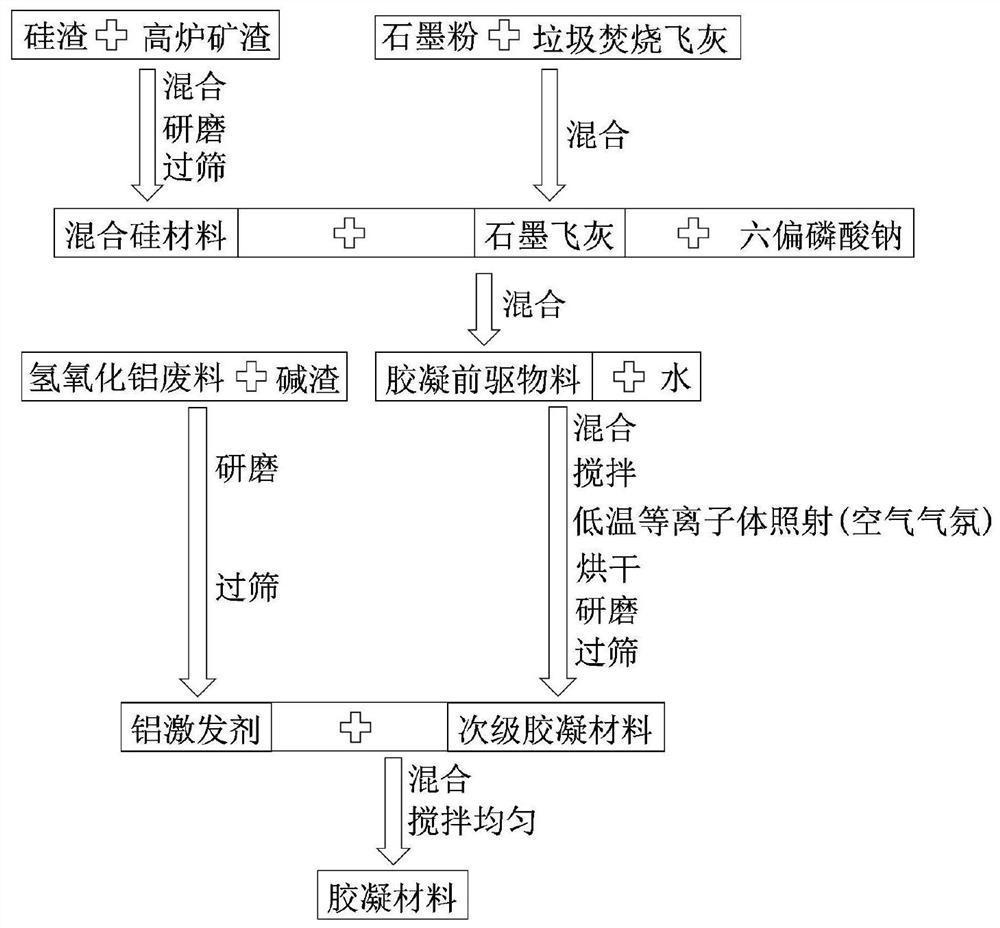

[0023] Preparation of cementitious material: as figure 1 As shown, silicon slag and blast furnace slag were weighed according to the mass ratio of silicon slag and blast furnace slag at 1:1, mixed and ground, and passed through a 200 mesh sieve to obtain a mixed silicon material; according to the mass ratio of graphite powder and waste incineration fly ash of 0.5:100 , 0.7:100, 0.9:100, 1:100, 3:100, 5:100, 5.5:100, 6.5:100, 7.5:100 respectively take graphite powder and refuse incineration fly ash, mix, get graphite fly ash; Weigh sodium hexametaphosphate, mixed silicon material, and graphite fly ash according to the mass ratio of sodium hexametaphosphate, mixed silicon material, and graphite fly ash of 2:10:100, and mix to obtain a gelled precursor material; according to the liquid-solid ratio of 1 mL: Mix 1mg of water and gelling precursor ma...

Embodiment 2

[0037] Effect of mass ratio of sodium hexametaphosphate, mixed silicon material, and graphite fly ash on the properties of prepared cementitious materials

[0038] Preparation of cementitious material: Weigh silicon slag and blast furnace slag respectively according to the mass ratio of silicon slag and blast furnace slag 1.5:1, mix and grind, pass through a 300-mesh sieve to obtain mixed silicon material; according to the mass ratio of graphite powder and waste incineration fly ash 5:100 respectively take graphite powder and refuse incineration fly ash, mix, get graphite fly ash; According to sodium hexametaphosphate, mixed silicon material, graphite fly ash mass ratio 2:5:100, 2:7:100, 2: 9:100, 0.5:10:100, 1:10:100, 1.5:10:100, 2:10:100, 2:15:100, 2:20:100, 4:10:100, 4:15: 100, 4:20:100, 6:10:100, 6:15:100, 6:20:100, 6.5:20:100, 7:20:100, 7.5:20:100, 6:21:100, 6:23:100 and 6:25:100 respectively weigh sodium hexametaphosphate, mixed silicon material and graphite fly ash, an...

Embodiment 3

[0045] Effect of the mass ratio of aluminum activator and secondary cementitious material on the properties of the prepared cementitious material

[0046] Preparation of cementitious material: Weigh silicon slag and blast furnace slag respectively according to the mass ratio of silicon slag and blast furnace slag 2:1, mix and grind, and pass through a 400-mesh sieve to obtain mixed silicon material; according to the mass ratio of graphite powder and waste incineration fly ash Take graphite powder and waste incineration fly ash at 5:100 respectively, and mix them to obtain graphite fly ash; weigh sodium hexametaphosphate, mix them according to the mass ratio of sodium hexametaphosphate, mixed silicon material, and graphite fly ash at 6:20:100. Silicon material and graphite fly ash were mixed to obtain gelled precursor material; water and gelled precursor material were mixed according to the liquid-solid ratio of 3mL:1mg, stirred at 480rpm, and simultaneously irradiated with low-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com