Method for preparing new clay material for 3D printing

A 3D printing and clay technology, applied in the production and application of clay products and ceramic materials, can solve the problems of poor chemical properties, unfavorable support and modeling of clay materials, and achieve the effect of good dimensional accuracy, easy molding, and promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of described novel 3D printing clay material comprises the following steps:

[0054] S1: Take the soil with a pH of 7.8-11.5, air-dry it naturally, put it into a planetary ball mill to grind, pass the soil powder through a 300-400 mesh sieve, and obtain the clay material of the raw material;

[0055] S2: crushing the stone through a 250-300 mesh sieve to obtain calcium carbonate powder;

[0056] S3: Treat plants, fallen leaves, and residues at 1200-1400°C to produce plant ash;

[0057]S4: Mix the clay material prepared in step S1, the calcium carbonate powder prepared in step S2, and the plant ash prepared in step S3 into a low-temperature pulverizer, and pulverize the mixture at a temperature of -95-108°C for 2- 3h, obtain 90-100 mesh material A after sieving;

[0058] S5: Add a specific synthetic agent to the material A prepared in step S4, raise the temperature to 150-160° C., knead for 4-5 hours at a rotation speed of 50-80 r / min, and then c...

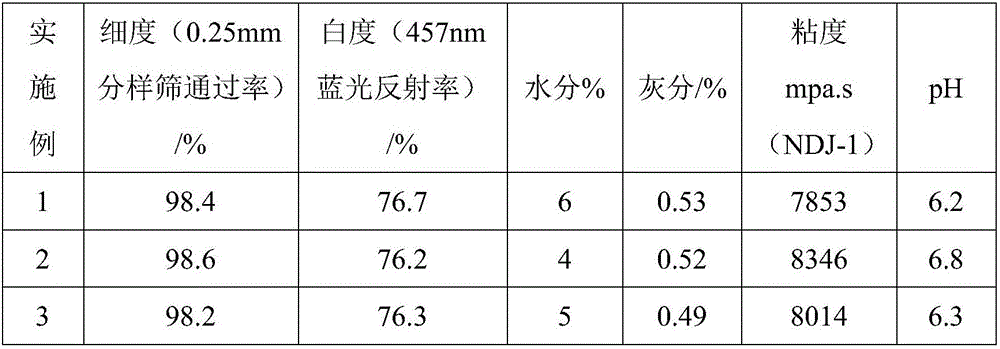

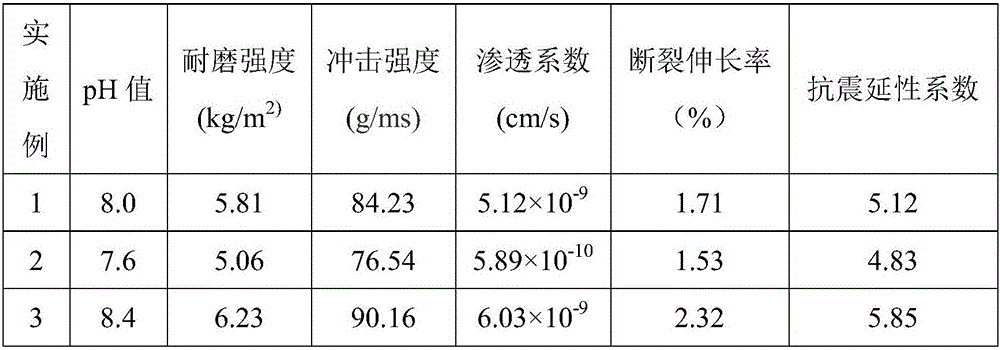

Embodiment 1

[0072] A new type of clay material for 3D printing, including raw materials in the following mass ratio: clay material: calcium carbonate powder: plant ash: specific synthetic agent: starch synthetic agent = 28:12:8:6:5;

[0073] The specific synthetic agent is in parts by weight, including the following raw materials: 18 parts of regulator, 15 parts of strengthening agent, 12 parts of stabilizer, 12 parts of bridging agent, 8 parts of toughening agent, 8 parts of thickening agent, stabilizer 6 parts, 4 parts of antifungal agent, 4 parts of terminator;

[0074] The regulator is JINHASS;

[0075] The strengthening agent is 701 powder strengthening agent;

[0076] The stabilizer is composed of salt gypsum, phosphogypsum, fluorogypsum, iron oxide, calcium oxide;

[0077] The bridging agent is an acrylic acid type compatibilizer;

[0078] The toughening agent is silicon carbide whisker;

[0079] The thickener is a cellulose ether thickener;

[0080] Described stabilizer is cl...

Embodiment 2

[0102] A new type of clay material for 3D printing, including raw materials with the following mass ratio: clay material: calcium carbonate powder: plant ash: specific synthetic agent: starch synthetic agent = 25:8:6:6:4;

[0103] The specific synthetic agent is in parts by weight, including the following raw materials: 15 parts of regulator, 10 parts of strengthening agent, 8 parts of stabilizer, 8 parts of bridging agent, 6 parts of toughening agent, 6 parts of thickener, stabilizer 4 parts, 2 parts of antifungal agent, 2 parts of terminator;

[0104] The regulator is JINHASS;

[0105] The strengthening agent is 701 powder strengthening agent;

[0106] The stabilizer is composed of salt gypsum, phosphogypsum, fluorogypsum, iron oxide, calcium oxide;

[0107] The bridging agent is an acrylic acid type compatibilizer;

[0108] The toughening agent is silicon carbide whisker;

[0109] The thickener is a cellulose ether thickener;

[0110] Described stabilizer is clay stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com