Process for preparing calcined soda by high salt low alkali forced-circulation carbonization

A technology of forced circulation and carbonization, which is applied in the field of soda ash production, can solve the problems of reduced product output, low product profit rate, and reduced raw material utilization rate, and achieves the effect of continuous production process, improved production efficiency, and improved raw material utilization rate.

Active Publication Date: 2010-11-10

HENAN ZHONGYUAN CHEM

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These two processes require that the amount of alkali and salt in the raw materials must be within the specified range, otherwise the utilization rate of raw materials will be greatly reduced, the output of products will be reduced, and ultimately the profit margin of the product will be relatively low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

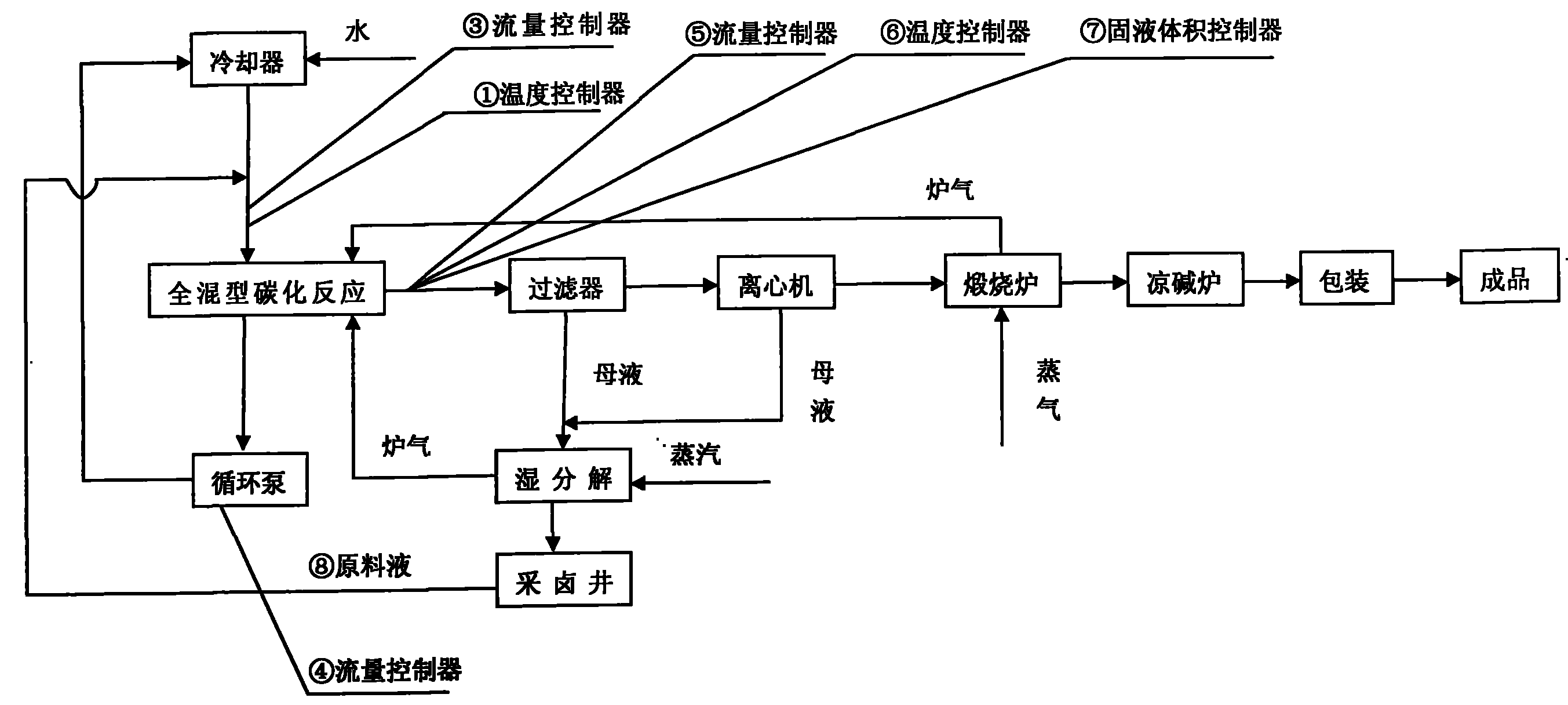

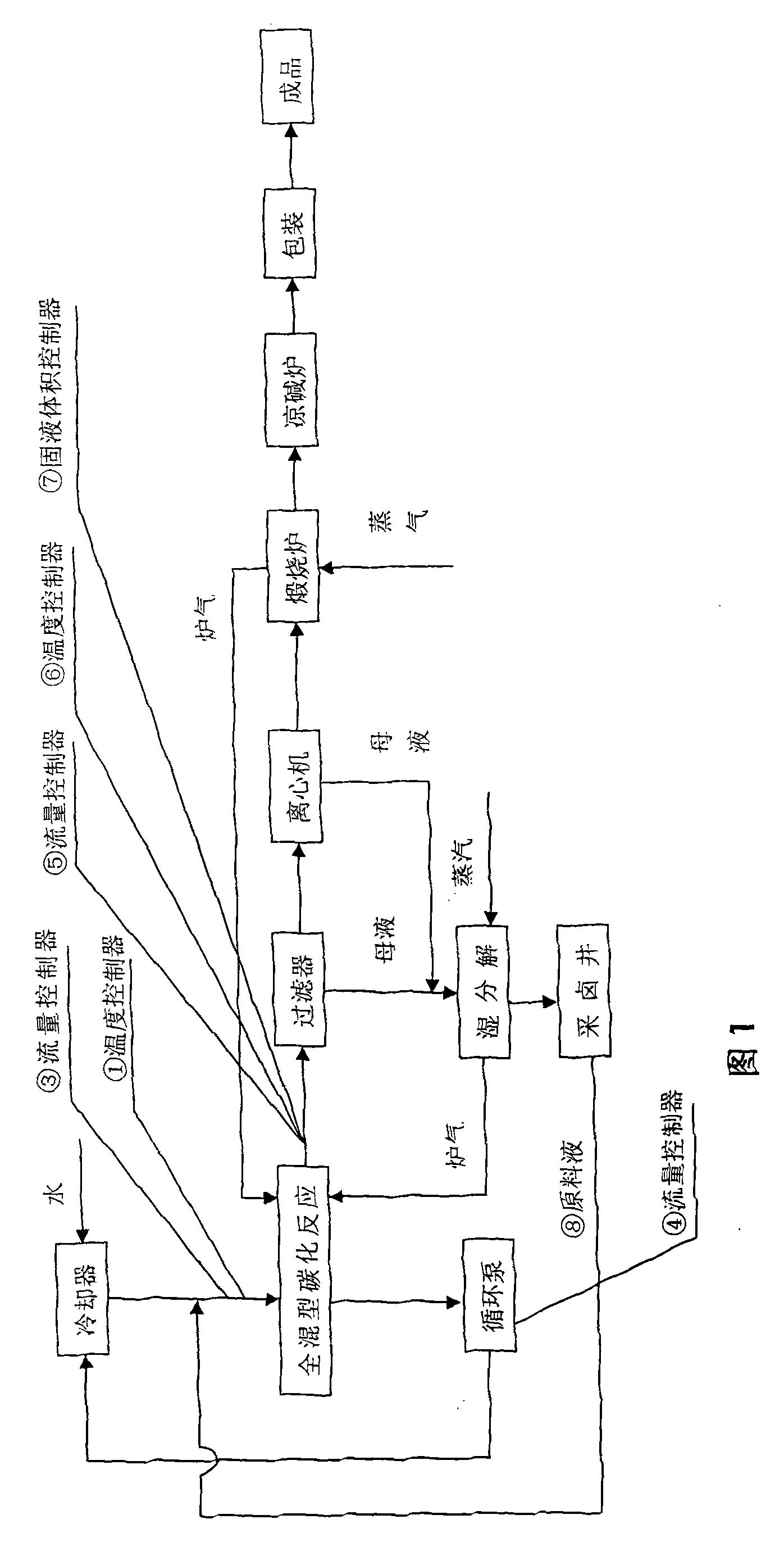

The invention discloses soda ash preparation technology by a high-salt low-alkali forced circulation carbonization method, which comprises the following steps that: a soda solution is pumped into a forced circulation full mixing type carbonization tank, and a device is orderly provided with a carbonization system, a separation system and a calcination system; a raw material liquid with the composition of Na2CO3, NaHCO3 and NaCl, and a temperature of between 50 and 52 DEG C and furnace air CO2 are injected into a circulation pump of the carbonization system respectively; and the raw material liquid passes through the carbonization system, the separation system and the calcination system, and finally reaches a packaging system to obtain a finished product of granular light soda ash. The technology mainly takes sesquibasic low-alkali high-salt as a raw material to pass through a full mixing type carbonization reactor through the steps of controlling process indexes, improves production efficiency, also improves the utilization rate of the raw material, realizes the fully-closed operation of the flow, and ensures that the production process is continuous, steady and safe.

Description

High-salt and low-alkali forced circulation carbonization process of soda ash Technical field The invention belongs to the technical field of soda ash production technology, and relates to a soda ash production process of sesquialka, high-salt and low-alkali lye through forced circulation and full-mixing carbonization method, in particular to a soda ash production process of high-salt and low-alkali forced circulation carbonization method. Background technique At present, the raw materials of the carbonization method are high-alkali and low-salt and high-alkali and high-salt, and the soda ash product is obtained through the processes of carbonization, filtration, centrifugation, calcination and packaging. These two processes require that the amount of alkali and salt in the raw materials must be within a specified range, otherwise the utilization rate of raw materials will be greatly reduced, the output of products will be reduced, and ultimately the profit margin of the pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01D7/12

Inventor 孙朝晖李山岭李守刚李保平刘二明孔涛于建平陈福连冯花梅

Owner HENAN ZHONGYUAN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com