Preparation of a descaling and antiscaling agent for ash removal water system

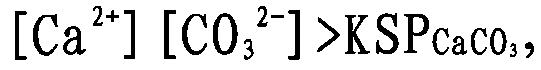

An anti-scaling agent and gray water technology, applied in the field of anti-scaling and anti-scaling agents, can solve problems such as scaling of return water pumps, valves and pipelines, endangering the normal operation of the ash removal water reuse system, and decreased pump output, and achieves the elimination of easy Effects of hydrolysis, scaling prevention, and improvement of dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

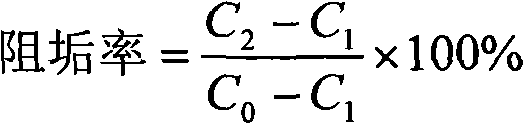

Examples

Embodiment 1

[0016] The components are prepared in parts by weight: 32 parts of itaconic acid-styrenesulfonic acid-acrylic acid copolymer, 33 parts of polyol phosphate, 22 parts of glycolic acid, and 19 parts of pure water;

[0017] Its other components: take 30 parts of itaconic acid-styrenesulfonic acid-acrylic acid copolymer, 30 parts of polyol phosphate, 20 parts of glycolic acid, and 20 parts of pure water;

[0018] Among them: take the preparation of itaconic acid-styrene sulfonic acid-acrylic acid copolymer, take 12 parts of itaconic acid, 6 parts of styrene sulfonic acid, 4 parts of isopropanol, and 34 parts of pure water, put them into the reaction kettle and stir, heat To 95°C, add 24 parts of acrylic acid and 2 parts of ammonium persulfate solution (diluted with 18 parts of pure water) dropwise at the same time, control the dropwise addition within 30 minutes, keep the temperature for 120 minutes, cool down to room temperature and discharge, and obtain light yellow and transparen...

Embodiment 2

[0022] Control 1 Commercially available hydroxyethylene diphosphonic acid, code-named HEDP

[0023] Control 2 commercially available aminotrimethylene phosphonic acid, code-named ATMP

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com