Aerated concrete block and production process thereof

A kind of air-entrained concrete and production process technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve environmental pollution and other problems, achieve stable chemical properties, good bonding effect, and freeze-resistant effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

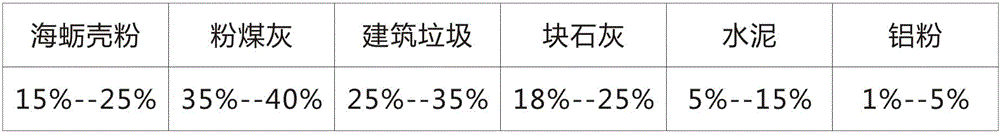

[0024] refer to figure 1 ,Such as figure 1 The shown aerated concrete block brick of the present invention is made of sea oyster shell powder 15%-25%, fly ash 35%-40%, construction waste 25%-35%, block lime 18% --25%, cement 5%--15%, aluminum powder 1%--5%.

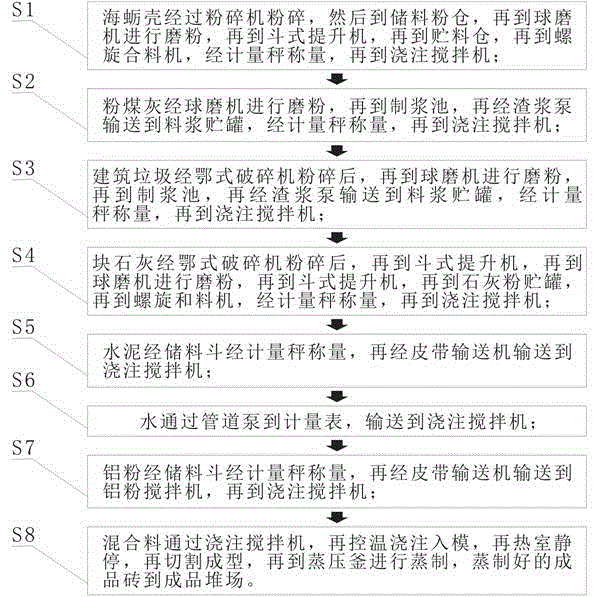

[0025] figure 2 Show a kind of air-entrained concrete block brick production technology of the present invention, comprise the following steps:

[0026] S1, sea oyster shells are pulverized by a pulverizer, then go to the storage powder bin, then go to the ball mill for grinding, then go to the bucket elevator, then go to the storage bin, and then go to the screw mixer, and then weighed by the weighing scale. Then to pouring mixer;

[0027] S2, the fly ash is pulverized by a ball mill, then sent to the slurry tank, then transported to the slurry storage tank by the slurry pump, weighed by the measuring scale, and then sent to the pouring mixer;

[0028] S3, after the construction waste is crushed by the jaw crusher,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com