Production method of heavy soda ash

A technology of heavy soda ash and production method, applied in chemical instruments and methods, alkali metal compounds, alkali metal carbonates, etc., can solve problems such as unsuitable scarring, reduce environmental pollution and resource waste, reduce efflux, The effect of reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

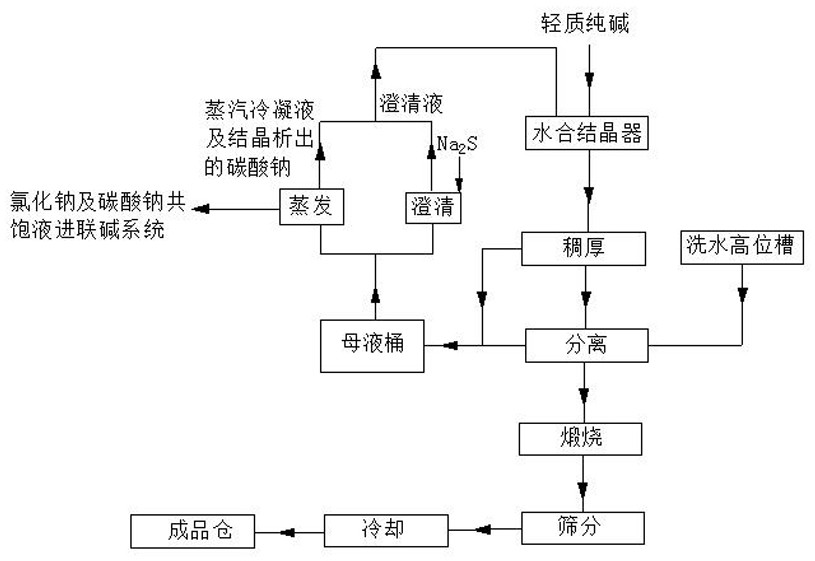

Image

Examples

Embodiment 1

[0028] Add light soda ash and saturated sodium carbonate solution with a weight percentage of 1:0.7 into the hydration crystallizer, and carry out hydration reaction at a temperature of 105°C for 5 minutes. The hydrated crystal slurry has a solid-liquid volume ratio of 35%. The hydrated crystal slurry is sent to a thickener until the solid-liquid volume ratio is 45%, and then enters the centrifuge for dehydration. The water volume is 220kg / t 重质纯碱 Wash away the salt and other impurities in the soda monohydrate, after dehydration, enter the heavy soda ash furnace for drying, and then carry out particle size screening and cooling to obtain low-salt heavy soda ash. Water enters the mother liquor bucket. 20% of the volume of heavy soda ash mother liquor in the mother liquor tank is evaporated by evaporation equipment, sodium carbonate monohydrate crystals and steam condensate are mixed and recycled to the hydration crystallizer in the original device, and the remaining sodium chlo...

Embodiment 2

[0031] Add light soda ash and saturated sodium carbonate solution with a weight percentage of 1:0.9 into the hydration crystallizer, and perform hydration reaction at a temperature of 95°C for 8 minutes. The solid-liquid volume ratio of the hydrated crystal slurry is 29%. The hydrated crystal slurry is sent into a thickener until the solid-liquid volume ratio is 42%, and then enters the centrifuge for dehydration. The amount of water is 200kg / t 重质纯碱 Wash away the salt and other impurities in the soda monohydrate, after dehydration, enter the heavy soda ash furnace for drying, and then carry out particle size screening and cooling to obtain low-salt heavy soda ash. Water enters the mother liquor bucket. 30% of the volume of heavy soda ash mother liquor in the mother liquor tank is evaporated by evaporation equipment, sodium carbonate monohydrate crystals and steam condensate are mixed and recycled to the hydration crystallizer in the original device, and the remaining sodium c...

Embodiment 3

[0034] Add light soda ash and saturated sodium carbonate solution with a weight percentage of 1:1 into the hydration crystallizer, and carry out hydration reaction at a temperature of 100°C for 10 minutes. The solid-liquid volume ratio of the hydrated crystal slurry is 25%, and the hydrated crystal slurry is sent to a thickener until the solid-liquid volume ratio is 35%, and then dehydrated in a centrifuge, and washed with the washing water in the high-level tank. 180kg / t 重质纯碱 Wash away the salt and other impurities in the soda monohydrate, after dehydration, enter the heavy soda ash furnace for drying, and then carry out particle size screening and cooling to obtain low-salt heavy soda ash. Water enters the mother liquor bucket. 30% of the volume of heavy soda ash mother liquor in the mother liquor tank is evaporated by evaporation equipment, sodium carbonate monohydrate crystals and steam condensate are mixed and recycled to the hydration crystallizer in the original device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com