Process for preparing high-quality heavy soda ash by using crude sodium bicarbonate

A technology of sodium bicarbonate and heavy soda ash, applied in carbonate preparations, alkali metal carbonates, alkali metal compounds, etc., can solve the problems of high consumption of brine, low total alkalinity of brine, and impact, etc. The effect of production cost, product quality improvement, and soda ash quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

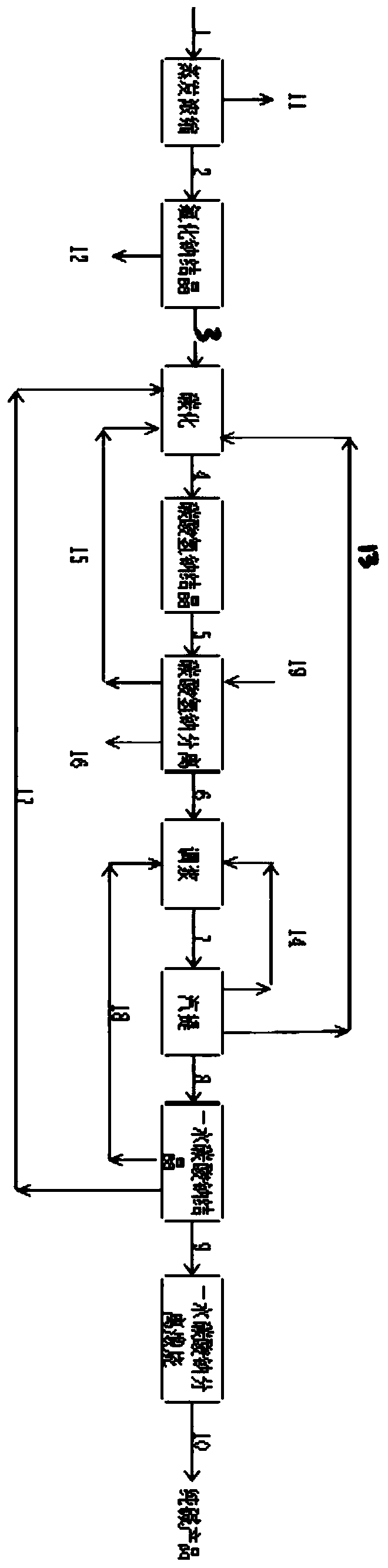

[0037] Such as figure 1 As shown, a process for producing high-quality heavy soda ash by using crude sodium bicarbonate, high-saline-alkaline brine is obtained through the brine extracted from underground trona mines or directly drawn from the ground. The hypersaline brine 1 collected from the ground is composed of sodium chloride: 12.93wt%, total alkalinity 2.43wt%, sodium sulfate: 1.41wt%, potassium chloride: 0.43wt%.

[0038] (1) Evaporation and concentration of high-salinity brine: high-salt-alkaline brine 1 reaches the crystallization point of sodium chloride through evaporation and concentration, and obtains a concentrated product, that is, sodium chloride saturated solution 2, and water vapor 11 is also generated during the evaporation and concentration process;

[0039] (2) Sodium chloride crystallization separation: the saturated sodium chloride solution 2 is further evaporated, and sodium chloride crystals are separated out to obtain sodium chloride product 12 and al...

Embodiment 2

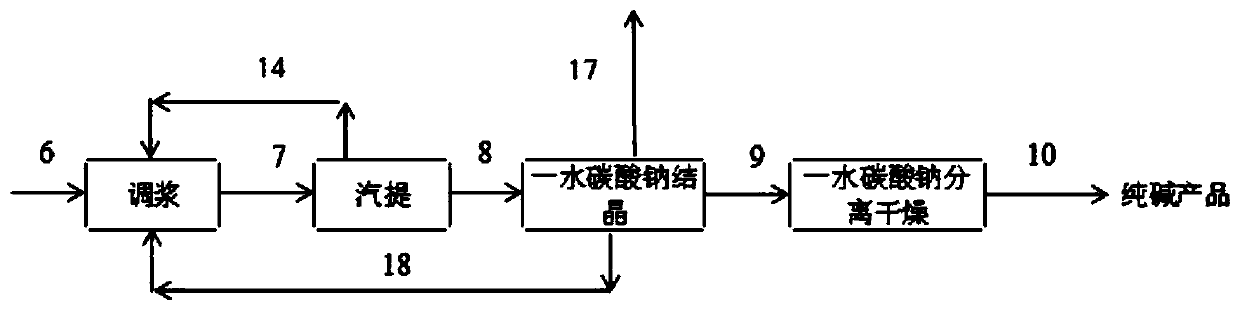

[0048] Such as figure 2 Shown, a kind of technique that utilizes thick sodium bicarbonate to produce high-quality heavy soda ash, concrete technological process is as follows: thick sodium bicarbonate is the thick sodium bicarbonate filter cake that obtains from certain trona production process, and its sodium chloride content is about 3300ppm, TOC content is about 2000ppm.

[0049] (1) Slurry stripping: mix the thick sodium bicarbonate 6 with water to obtain the sodium bicarbonate slurry 7, adjust the slurry to 25% solid content, and use steam to remove part of the sodium bicarbonate in the sodium bicarbonate slurry 7 in the stripping tower Decompose into sodium carbonate, carbon dioxide and water to obtain stripping complete liquid 8; use a stripping tower to decompose most of the sodium bicarbonate and carry out monohydrate alkali crystallization, the stripping temperature is 146 ° C, and the stripping pressure is 3.8 barg.

[0050] (2) Crystallization of sodium carbonate...

Embodiment 3

[0054] Such as figure 2 Shown, a kind of technology that utilizes crude sodium bicarbonate to produce high-quality heavy soda ash, concrete technological process is as follows: Crude sodium bicarbonate is the thick heavy alkali that ammonia soda factory obtains by carbonization and heavy alkali separation, and its typical composition is: bicarbonate Sodium: 76.04wt%, sodium carbonate: 6.68wt%, sodium chloride: 0.45wt%, ammonium bicarbonate: 3.09wt%, water: 13.74wt%.

[0055] (1) Slurry stripping: thick sodium bicarbonate 6 is mixed with water to obtain sodium bicarbonate slurry 7, and slurry is adjusted to a concentration of 25-35wt% sodium bicarbonate, and steam is used to remove sodium bicarbonate slurry 7 in the stripping tower. Part of the sodium bicarbonate is decomposed into sodium carbonate, carbon dioxide and water, and the stripping complete liquid 8 is obtained; most of the sodium bicarbonate is decomposed by a stripping tower, followed by monohydrate alkali crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com