Recovering treatment of hydrated hydrazine by-product saline-alkali by urea method

A method of hydration and saline-alkali technology, which is applied in the field of saline-alkali recovery and treatment by-products of urea hydrazine hydrate, can solve the problems of low recovery rate of by-products, incomplete recovery, incomplete recovery, etc. Ease of recovery of hydrazine hydrate and increase in product value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

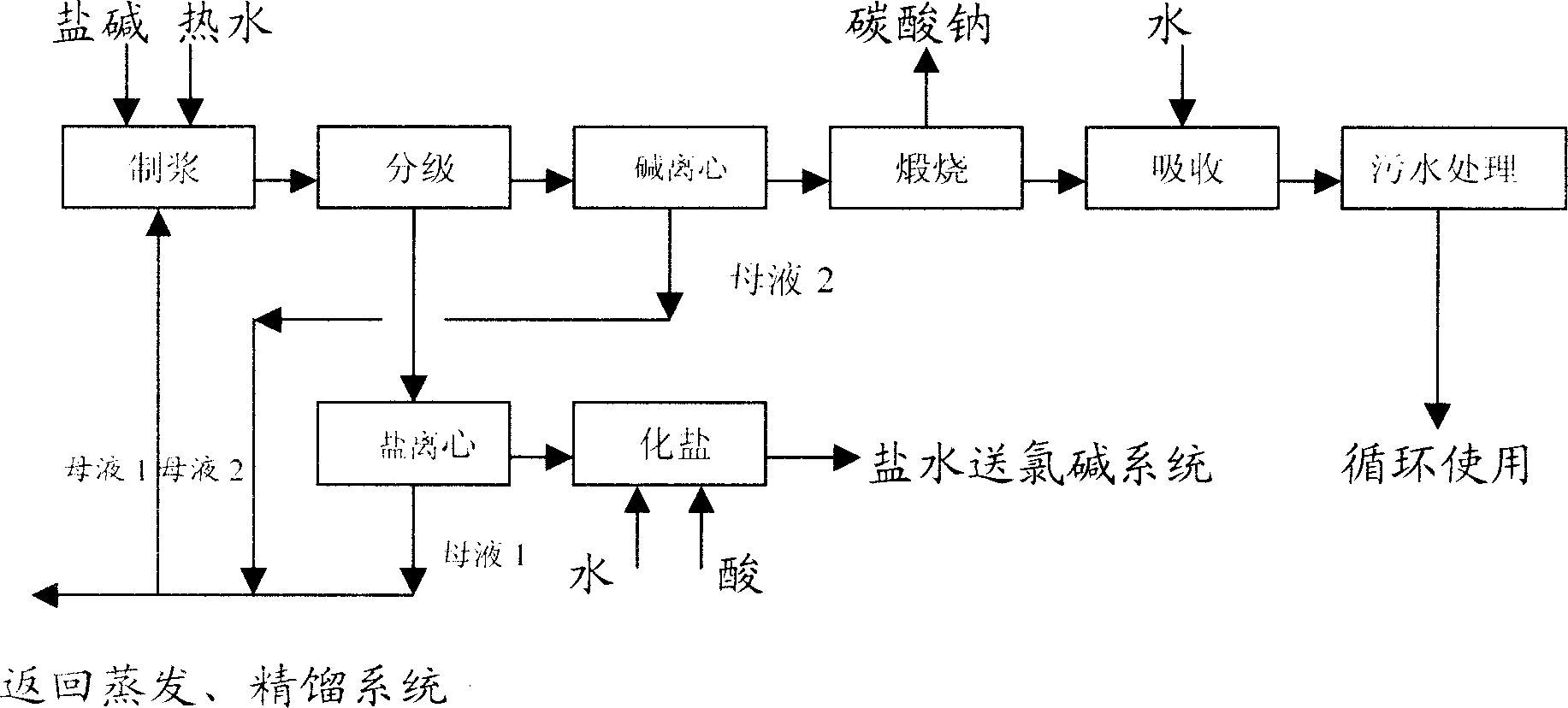

Image

Examples

Embodiment 1

[0028] Embodiment 1: the above-mentioned saline-alkali mixture is processed according to the following steps:

[0029] (a) The pulping step uses hot water as the pulping medium for pulping: pump the 90°C hot water discharged from the system into the pulping tank with stirring, start stirring and continuously add hydrazine hydrate to produce saline and alkali The mixture is made into a supersaturated slurry with a solid-to-liquid ratio of 0.8:1 and sodium carbonate, sodium chloride, caustic soda, and hydrazine hydrate;

[0030] (b) Separation step of salt slurry and alkali slurry: pump the slurry prepared in step (a) into the suspension device for classification, and use the principle of different gravity of salt slurry and alkali slurry to separate salt slurry and alkali slurry , respectively to obtain a solid-liquid ratio of 1: 1 salt slurry and 0.6: 1 alkali slurry;

[0031](c) The processing step of salt slurry: the mother liquor obtained after the salt slurry classified i...

Embodiment 2

[0034] Embodiment 2: prepare hydrazine hydrate according to above-mentioned conventional steps, after the hydrazine hydrate in the hydrazine hydrate crude solution, water evaporation, the chemical composition of the saline-alkali mixture obtained is as follows:

[0035] Sodium chloride: 30% Sodium carbonate: 15% Caustic soda: 10% N 2 h 4 ·H 2 O: 0.4% and the rest are water and other trace impurities. The above-mentioned saline-alkali mixture is processed as follows:

[0036] (a) Pulping step: use hot water as the pulping medium for pulping: pump the 65°C hot water discharged from the system into the pulping tank with stirring, start stirring and continuously add hydrazine hydrate by-product salt Alkali mixture, made into a supersaturated slurry with a solid-to-liquid ratio of 0.3:1 and containing sodium carbonate, sodium chloride, caustic soda, and hydrazine hydrate;

[0037] (b) Separation step of salt slurry and alkali slurry: pump the slurry prepared in step (a) into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com