Process for preparing high-quality low-salt low-potassium heavy sodium carbonate and ammonium chloride

A technology for heavy soda ash and ammonium chloride, which is applied in the production process of soda ash and ammonium chloride, can solve the problems of high energy consumption, high raw material consumption, and high physical strength, and achieve short process flow, easy access to raw materials, and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

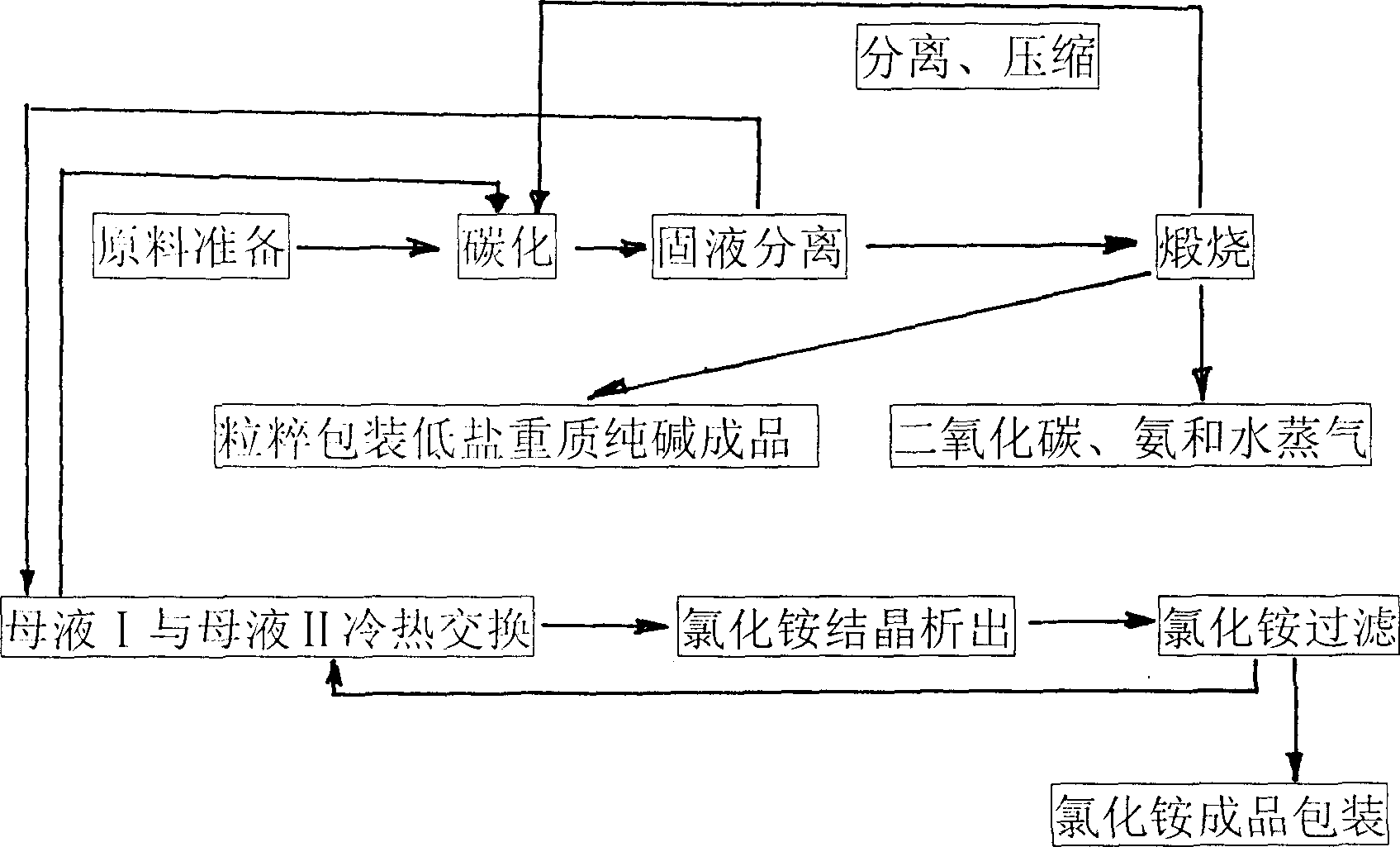

[0053] A. Raw material preparation

[0054] Raw materials include 6.0 tons of solid ammonium bicarbonate with a nitrogen content greater than 17.1%, carbon dioxide, 60 cubic meters of semi-ammonia mother liquor II with a concentration of 120 g / L of ammonium chloride and 210 g / L of sodium chloride;

[0055] B. Carbonization

[0056] In the carbonization tower, 60 cubic meters of semi-ammonium mother liquor II are first added, and the carbon dioxide gas compressed by the compressor from the calcination reactor is introduced at a temperature of 24 to 48 ° C, and then 6.0 tons of solid ammonium bicarbonate are added for carbonization to obtain qualified Sodium bicarbonate liquid;

[0057] C. Separation of material and liquid

[0058] The sodium bicarbonate feed liquid obtained after the carbonization is separated through a centrifuge to obtain 13 tons of granular wet sodium bicarbonate and 68 cubic meters of liquid mother liquor 1, which contains less than 4% sodium chloride in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com