High-salinity coal mine water standard treatment and resource utilization device and use method thereof

A technology with high salinity and mine water, which is applied in mining wastewater treatment, oxidized water/sewage treatment, water/sewage treatment, etc. It can solve the problems of large consumption of softening agents, increased sludge volume, and expensive caustic soda. Achieve the effect of reducing the cost of softening and hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

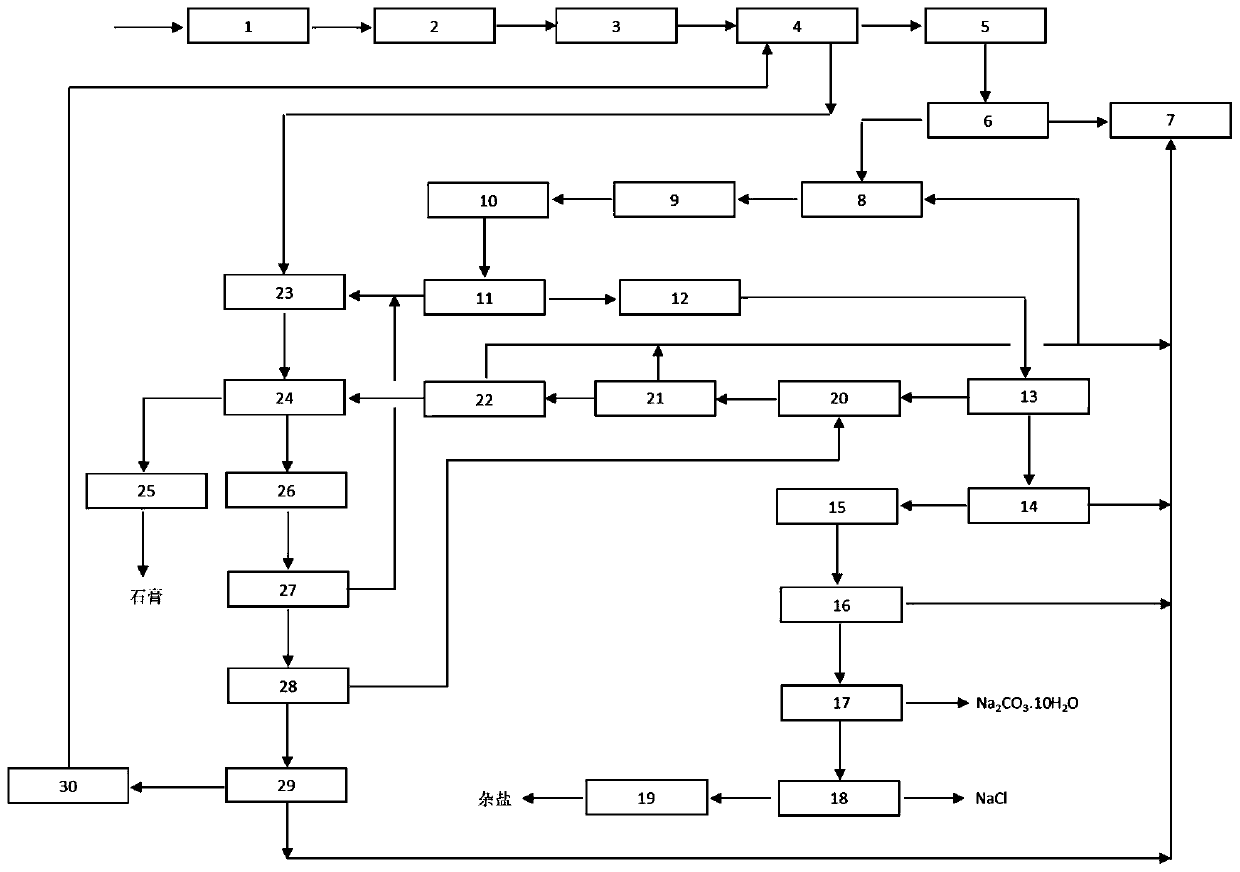

[0040] Attached below figure 1 The present invention will describe in detail the high-salinity coal mine mine water standard treatment and resource utilization device and its use method.

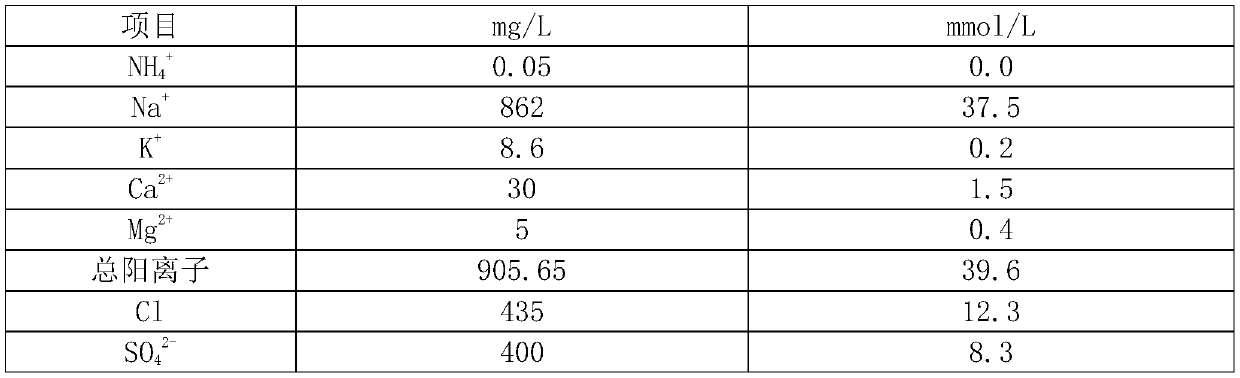

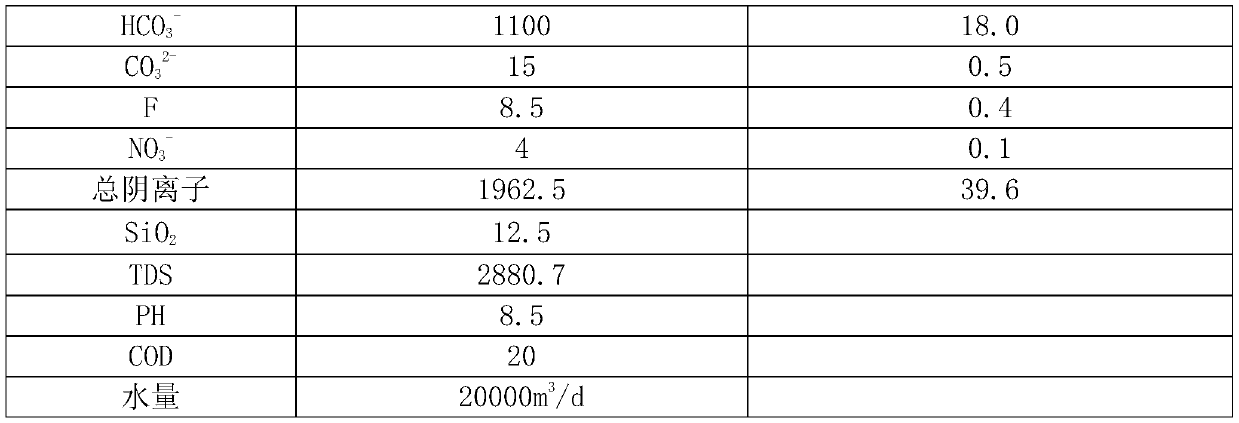

[0041] A high-salinity coal mine water standard treatment and resource utilization device, the high-salinity coal mine water standard treatment and resource utilization device includes: a homogeneous adjustment tank 1, a high-density clarification tank 2, a gravity filter Pool 3, sodium bed device 4, ultrafiltration device 5, reverse osmosis device 6, reuse water tank 7, ozone reaction tank 8, concentrated water high-density clarification tank 9, multimedia filter 10, concentrated water weak acid resin bed 11, concentrated Water ultrafiltration device 12, nanofiltration device 13, nanofiltration product water reverse osmosis device 14, concentrated brine tank 15, nanofiltration product water evaporation concentration device 16, sodium carbonate decahydrate freeze crystallization device 17, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com