Comprehensive utilization high advantage zero discharge seawater desalination production technology

A production process, zero-emission technology, applied in chemical instruments and methods, seawater treatment, alkali metal chlorides, etc., can solve the problems of high production cost, high price, marine ecological environment pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

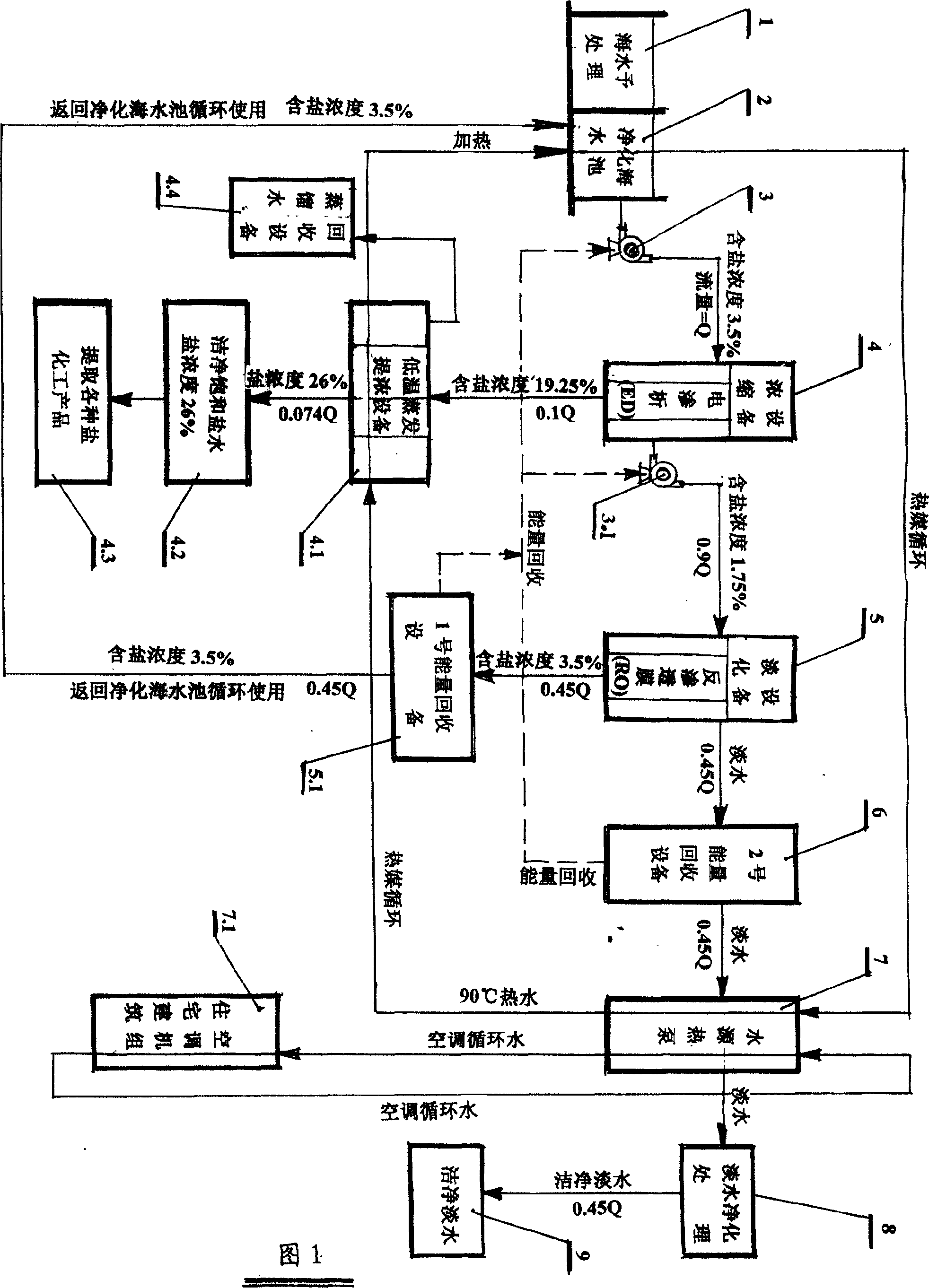

[0040] The specific implementation, features, and effects of the comprehensive utilization, high-efficiency and zero-emission seawater desalination combined production process proposed by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0041] Please refer to Figure 1, the present invention comprehensively utilizes the seawater desalination combined production process with high efficiency and zero discharge, which mainly includes seawater pretreatment 1, seawater purification pool 2, delivery pump 3, concentration equipment electrodialysis (ED) 4, low temperature Evaporation and concentration equipment 4.1, clean saturated brine 4.2, extraction of various salt chemical products 4.3, distilled water recovery equipment 4.4, desalination equipment reverse osmosis membrane (RO) 5, No. 1 energy recovery equipment 5.1, No. 2 energy recovery equipment 6, water source heat pump 7. Fresh water purification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com