Zero-discharge treatment method and system for high-carbonate mine water

A treatment method, mine water technology, applied in the field of water treatment, can solve the problem of high salt content in wastewater, and achieve the effect of simple process flow, high stability and high value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

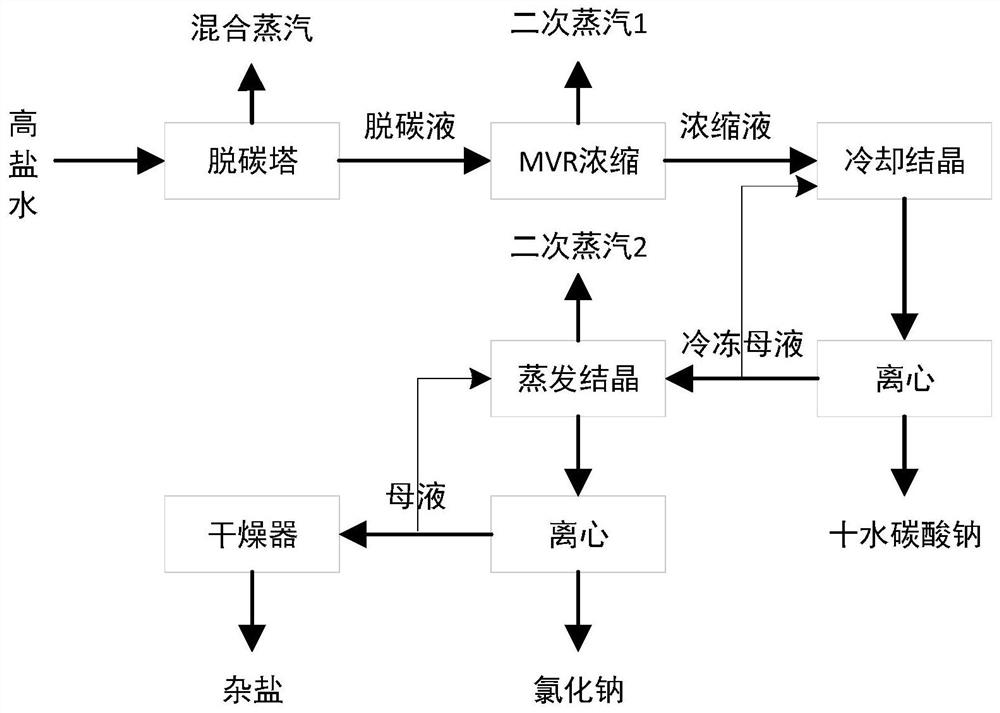

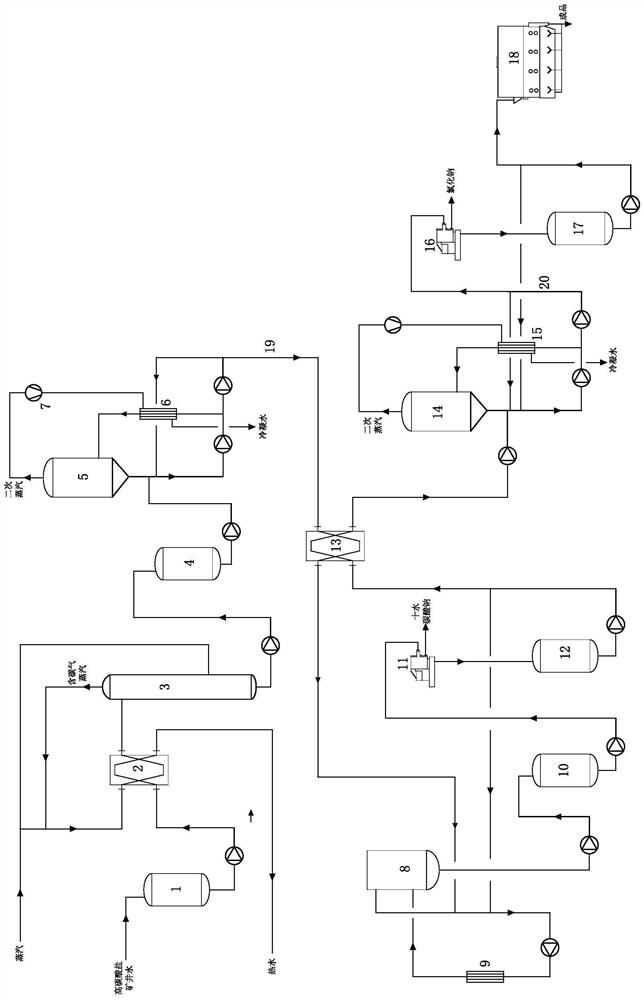

[0053] The core of the present invention is to provide a zero-discharge treatment method for high-carbonate mine water, a process flow chart of a specific embodiment is shown in figure 1 , which is referred to as the first embodiment, the method includes the following steps:

[0054] Step a, decarbonization; the mine water is preheated to a temperature of 85°C ± 5°C, and enters the decarbonization tower for stripping and decarbonization to obtain high-salt water and CO-containing salt water with sodium carbonate and sodium chloride as the main components. 2 mixed steam;

[0055] Step b, evaporation and concentration; the effluent in step a passes through the buffer tank, mixes with the effluent of the primary evaporator, and then enters the primary heat exchanger, and the superheated material after heat exchange enters the primary evaporator for flash evaporation to obtain an evaporation concentrate and secondary steam, the temperature of the evaporated concentrate is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com