Production technology for producing sodium fluoride from sodium fluosilicate and co-producing white carbon black

A technology of sodium fluorosilicate and production process, which is applied in the fields of high-concentration salt-containing ammonia nitrogen wastewater treatment and fluorosilicon resource utilization, can solve the problem that it is difficult for white carbon black to reach the standard used in the rubber industry, and the purity of sodium fluoride is difficult to reach first-class products. requirements and other issues, to avoid frequent updates of mother liquor, prevent aggregation, and achieve good separation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: a kind of technique that utilizes sodium fluorosilicate to produce sodium fluoride to co-produce white carbon black, take sodium fluorosilicate and sodium carbonate as raw material, the molar ratio of sodium fluorosilicate and sodium carbonate is 1:1.05, It mainly includes the following steps:

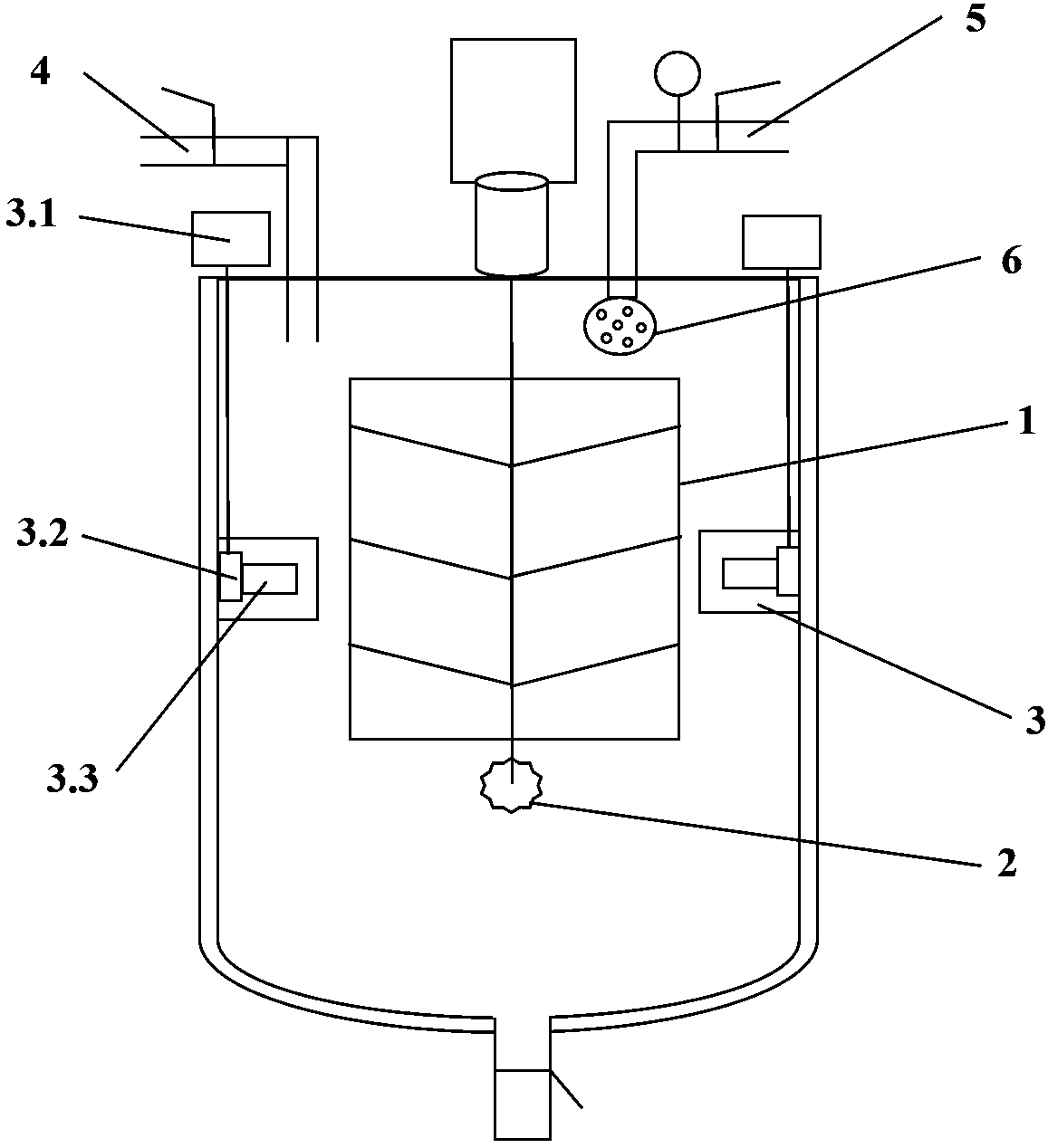

[0026] (1) Pulping: Add sodium fluorosilicate to the feeding tank 1 with mother liquor according to the feeding ratio, stir and dissolve to form sodium fluorosilicate slurry, and transport it to the reactor through the head tank;

[0027] (2) Alkali dissolving: add sodium carbonate to the feeding tank 2, dissolve it with the mother liquor at the same time, stir to form a sodium carbonate solution of about 30%, filter to remove insoluble impurities, and transport it to the reactor through the head tank;

[0028] (3) Reaction: transport the sodium fluorosilicate slurry to the ultrasonic reactor, heat the steam to 90°C and slowly add the sodium carbonate solution to s...

Embodiment 2

[0032] Embodiment 2: A kind of technology that utilizes sodium fluorosilicate to produce sodium fluoride to co-produce white carbon black, take sodium fluorosilicate and sodium carbonate as raw material, the feeding molar ratio of sodium fluorosilicate and sodium carbonate is 1:1.25, It mainly includes the following steps:

[0033] (1) Pulping: Add urea (the amount is 1.0% of the mass of the mother liquor) to the feeding tank 1 with the mother liquor, add sodium fluorosilicate according to the feeding ratio, stir and dissolve to form a sodium fluorosilicate slurry, and transport it through the elevated tank to the reactor;

[0034] (2) Alkali dissolving: add sodium carbonate to the feeding tank 2, dissolve it with the mother liquor at the same time, stir to form a sodium carbonate solution of about 30%, filter to remove insoluble impurities, and transport it to the reactor through the head tank;

[0035] (3) Reaction: Transport the sodium fluorosilicate slurry to the ultrason...

Embodiment 3

[0039]Embodiment 3: A kind of technology that utilizes sodium fluorosilicate to produce sodium fluoride to co-produce white carbon black, take sodium fluorosilicate and sodium carbonate as raw material, the feeding molar ratio of sodium fluorosilicate and sodium carbonate is 1:1.20, It mainly includes the following steps:

[0040] (1) Pulping: Add urea (the amount is 2.5% of the mass of the mother liquor) to the feeding tank 1 containing the mother liquor, add sodium fluorosilicate according to the feeding ratio, stir and dissolve to form a sodium fluorosilicate slurry, and transport it through the elevated tank to the reactor;

[0041] (2) Alkali dissolving: add sodium carbonate to the feeding tank 2, dissolve it with the mother liquor at the same time, stir to form a sodium carbonate solution of about 30%, filter to remove insoluble impurities, and transport it to the reactor through the head tank;

[0042] (3) Reaction: Transport the sodium fluorosilicate slurry to the ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com