Preparation method of frozen noodles added with food microemulsion

A microemulsion and noodle technology, applied in the field of food processing, can solve problems such as nutritional imbalance, oil, protein, carbohydrate ratio imbalance, and inability to meet dietary needs, etc., to achieve long shelf life, improved color and texture quality, and excellent quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

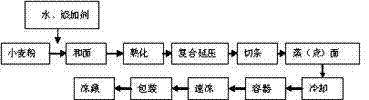

Method used

Image

Examples

Embodiment 1

[0019] a. Preparation of microemulsion: Take 1g of peanut oil, 8g of compound emulsifier (2.7g of glyceryl monolaurate, 2.7g of sodium stearoyl lactylate, 2.5g of sucrose fatty acid ester), 1g of propylene glycol, put them in a beaker, stir and add water to prepare into a microemulsion;

[0020] b. Weigh 100g of flour, 30g of distilled water, 1g of iodized salt, 0.1g of edible alkaline noodles, and 0.3g of microemulsion, and stir for 12 minutes; pour the reconciled flour into a clean ziplock bag, and let it stand and mature for 20 minutes ; Pour the cured flour wadding into a noodle press and press it into a noodle strip, and carry out continuous rolling three times. The first calendering obtains a noodle strip with a thickness of 2.0mm, and the second calendering obtains a noodle strip with a thickness of 1.6mm. Obtain a noodle strip with a thickness of 1.1mm; then cut the noodle strip into strips on a noodle cutter to obtain noodles with a width of 3.4mm, and pick out the in...

Embodiment 2

[0023] a. Preparation of microemulsion: Take 1g of peanut oil, 10g of compound emulsifier (3.2g of glyceryl monolaurate, 3.2g of sodium stearoyl lactylate, 3g of sucrose fatty acid ester), 1.5g of propylene glycol, put them in a beaker, stir and add water to prepare into a microemulsion;

[0024] b. The difference between this step and step b of Example 1 is that the added amount of the microemulsion is 0.5% of the flour weight (0.5g / 100g flour).

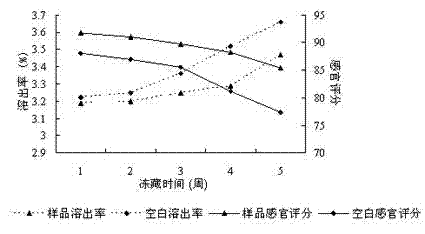

[0025] After the product prepared in this example was frozen and stored at -18°C for one month, the dissolution rate of the finished product after cooking was small, the color of the noodles was milky white, the elasticity was good, the taste was the same as that of fresh noodles, and the sensory quality was obviously better than that without adding microemulsion. Frozen noodles. This method prepares the frozen noodle product (sample) and the ordinary frozen noodle product (blank). figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com