Production method for naphthalene high-concentration water reducer

A production method and technology of water reducing agent are applied in the production field of naphthalene-based high-concentration water reducing agent, which can solve the problems of increasing waste residue, mild reaction, waste of raw materials, etc., and achieve the effects of improving conversion rate, reducing discharge and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

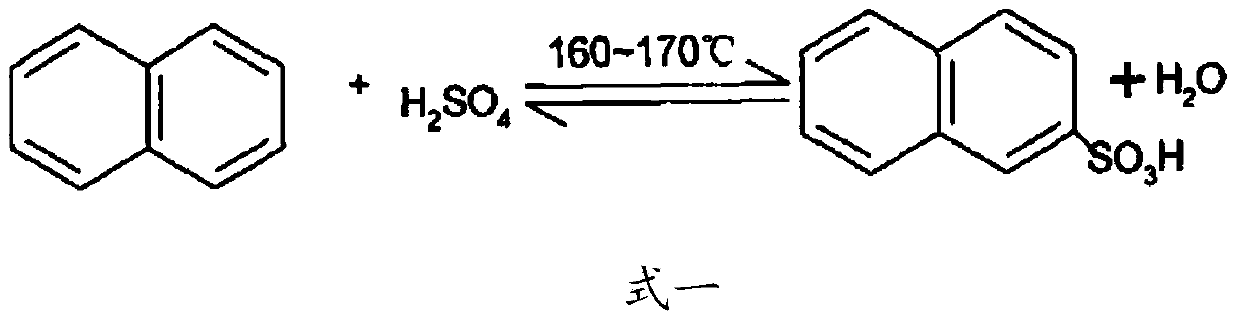

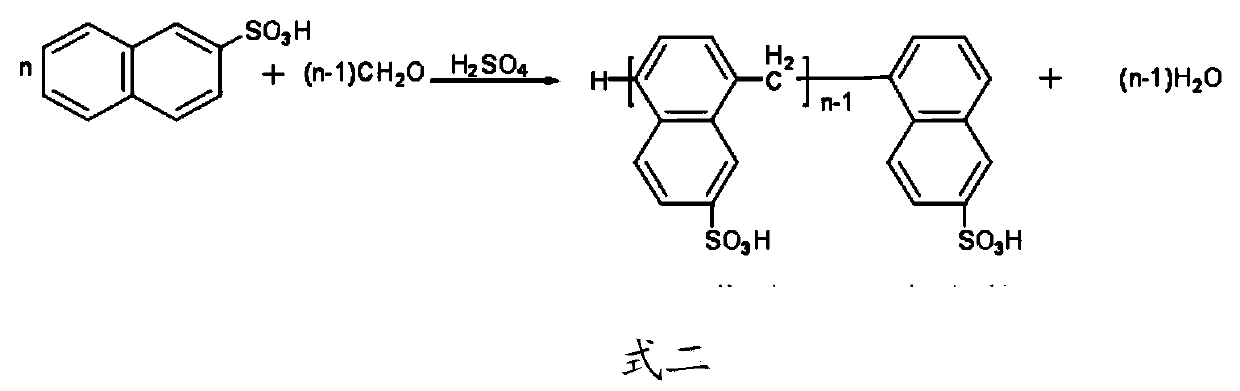

Method used

Image

Examples

Embodiment 1

[0028] A production method of a naphthalene-based high-concentration water-reducing agent is carried out according to the following steps:

[0029] 1) Raw material preparation: industrial naphthalene: 4400KG; 98% concentrated sulfuric acid: 3910KG; 37% formaldehyde: 2630KG.

[0030] 2) When the material temperature of the naphthalene storage tank is 130 ℃, put into industrial naphthalene;

[0031] 3) Sulfonation: when the temperature of industrial naphthalene rises to 150°C, start to add concentrated sulfuric acid, and add it at one time at a uniform speed for 25 minutes; after adding acid, carry out sulfonation reaction at 160°C; in the sulfonation process, Increase solvent circulation and remove residual solvent steps to ensure the full progress of the reaction; sulfonation acidity is controlled at 26%;

[0032] 4) Hydrolysis: add water to the reaction solution in step 3), hydrolyze at 110° C. for 15 minutes, and control the hydrolysis acidity at 22%;

[0033] 5) Condensat...

Embodiment 2

[0036] A production method of a naphthalene-based high-concentration water-reducing agent is carried out according to the following steps:

[0037] 1) Raw material preparation: industrial naphthalene: 4400KG; 98% concentrated sulfuric acid: 3910KG; 37% formaldehyde: 2630KG.

[0038] 2) When the material temperature of the naphthalene storage tank is 133°C, put into industrial naphthalene;

[0039] 3) Sulfonation: when the temperature of industrial naphthalene rises to 150°C, start adding concentrated sulfuric acid, and add it at one time at a constant speed for 30 minutes; after adding acid, carry out the sulfonation reaction at 165°C; during the sulfonation process, Increase solvent circulation and remove residual solvent steps to ensure the full progress of the reaction; the sulfonation acidity is controlled at 27%;

[0040] 4) Hydrolysis: add water to the reaction solution in step 3), hydrolyze at 125° C. for 15 minutes, and control the hydrolysis acidity at 23%;

[0041]...

Embodiment 3

[0044] A production method of a naphthalene-based high-concentration water-reducing agent is carried out according to the following steps:

[0045] 1) Raw material preparation: industrial naphthalene: 4400KG; 98% concentrated sulfuric acid: 3910KG; 37% formaldehyde: 2630KG.

[0046] 2) When the material temperature of the naphthalene storage tank is 132°C, put into industrial naphthalene;

[0047] 3) Sulfonation: when the temperature of industrial naphthalene rises to 150°C, start to add concentrated sulfuric acid, and add it at one time at a constant speed for 28 minutes; after adding acid, carry out sulfonation reaction at 162°C; in the sulfonation process, Increase solvent circulation and remove residual solvent steps to ensure the full progress of the reaction; sulfonation acidity is controlled at 26%;

[0048]4) Hydrolysis: add water to the reaction solution in step 3), hydrolyze at 115° C. for 15 minutes, and control the hydrolysis acidity at 22%;

[0049] 5) Condensat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com