Preparation method of 5-methylpyrazine-2-carboxylic acid

A technology of methylpyrazine and dimethylpyrazine, applied in the field of preparation of 5-methylpyrazine-2-carboxylic acid, can solve the problems of unsuitability for industrial production, easy deep oxidation, poor selectivity, etc. The effect of high yield and conversion rate and product purity, improved yield and product purity, and good technical effect

Inactive Publication Date: 2010-10-20

常州市康瑞化工有限公司

View PDF1 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The operation steps of this synthetic route are also relatively complicated, and because potassium permanganate is used for oxidation, the cost is higher, and potassium permanganate has a strong oxidation ability, so the selectivity is poor, and it is easy to be deeply oxidized, resulting in not very good product quality, and also not Suitable for industrial production

As mentioned above, most of the existing methods for preparing 5-methylpyrazine-2-carboxylic acid have shortcomings such as long steps, complicated operation, low yield or high cost, and are not suitable for industrial production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Login to View More

Abstract

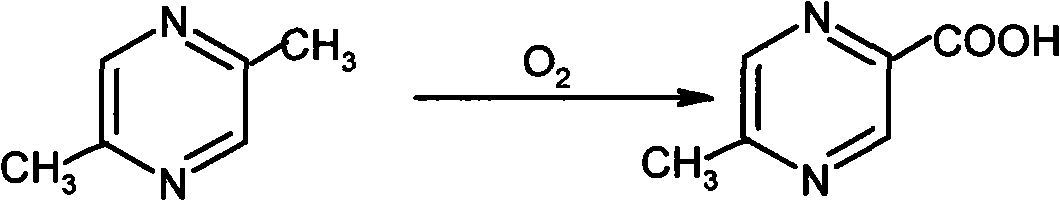

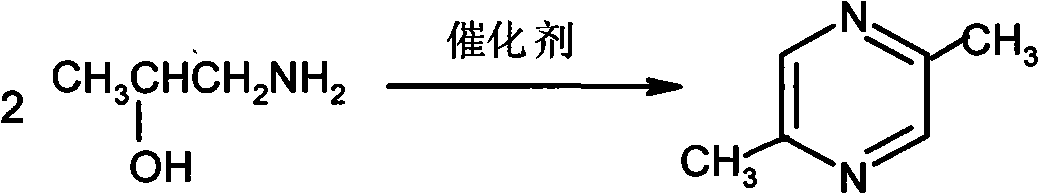

The invention relates to an improved preparation method of 5-methylpyrazine-2-carboxylic acid. The method comprises the following steps of: carrying out an oxidation reaction in an acetic acid solvent by using 2,5-dimethylpyrazine as raw materials, cobalt acetate and manganese acetate as catalysts and potassium bromide as a cocatalyst, wherein the temperature of the oxidation reaction is 90-110 DEG C; when a small quantity of unreacted 2,5-dimethylpyrazine is detected to be still in the reaction system, ending the oxidation reaction; and cooling reaction liquid obtained after the oxidation reaction is ended, crystallizing, filtering and drying to obtain the 5-methylpyrazine-2-carboxylic acid, wherein the 2,5-dimethylpyrazine is prepared by using isopropanolamine as raw materials, introducing H2 and N2 in the presence of an activated Al-Cu-Ag-Zn catalyst at 200-280 DEG C for a continuous feeding reaction and simply distilling the reaction liquid. The method has easy obtaining of raw materials, simple and convenient operation, short step, good product quality and low product cost and is more suitable for industrial production.

Description

technical field The present invention relates to a preparation method of an intermediate of a pharmaceutical raw material drug, in particular to a preparation method of 5-methylpyrazine-2-carboxylic acid. 5-Methylpyrazine-2-carboxylic acid is a pharmaceutical raw material drug " An important intermediate of "Acipimox" and "Glipizide". Background technique 5-Methylpyrazine-2-carboxylic acid is an important intermediate of pharmaceutical raw materials "Acipimox" and "Glipizide". Acipimox is a drug for treating hypertriglyceridemia, hypercholesterolemia, and hypertriglyceridemia combined with hypercholesterolemia, and glipizide is a second-generation sulfonylurea hypoglycemic drug. The preparation method of existing 5-methylpyrazine-2-carboxylic acid mainly contains following several kinds: The first is to use cis-2,3-diamino-2-butene-1,4-dinitrile as raw material, through cyclization with aceguvaldehyde and hydrolysis with sulfuric acid to obtain 2-methylpyrazine-5,6-dinit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07D241/24

Inventor 谢婷周爱军张瑞宽陈文华

Owner 常州市康瑞化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com