Polymerization ferric sulfate water treatment agent and preparation method thereof

A polymeric sulfuric acid and treatment agent technology, applied in the direction of ferric sulfate, flocculation/precipitation water/sewage treatment, etc., can solve the problems of impurity in the product, high production cost, unreachable, etc., and achieve low raw material consumption, low cost, and production fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

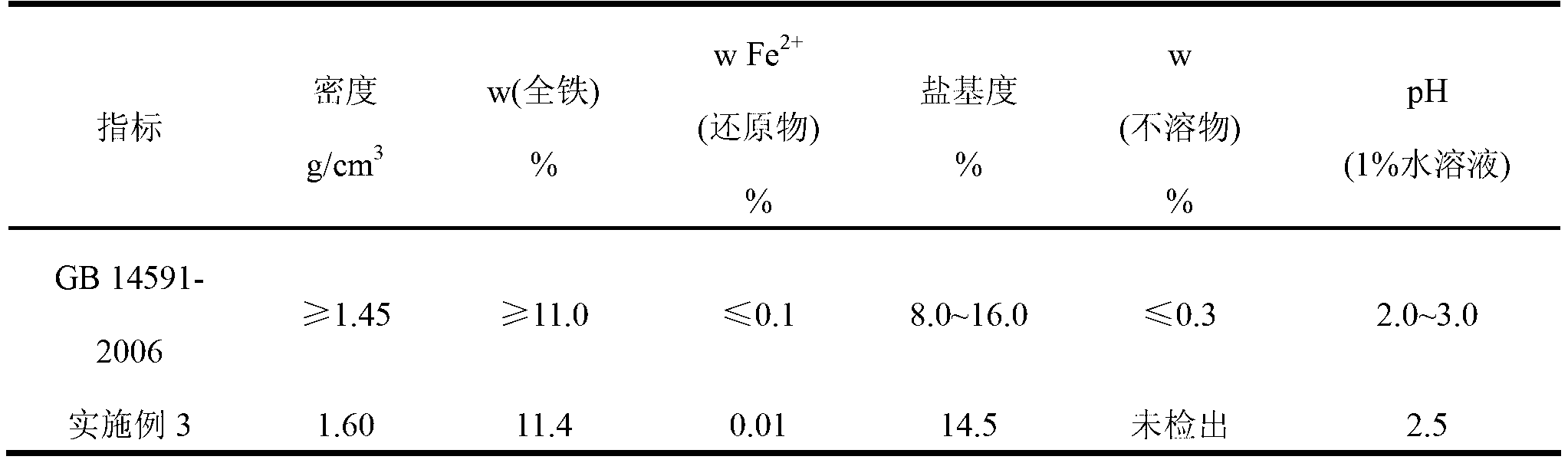

Embodiment 1

[0026] (1) Add 100.0g FeSO 4 ·7H 2 O mixes with 30.0g water, obtains mixed solution;

[0027] (2) 30wt% H under normal pressure 2 o 2 40.8 g of the aqueous solution was added to the mixed solution in step (1), and the temperature was lowered while stirring, and the temperature of the solution was controlled not to exceed 40°C to obtain a reaction solution;

[0028] (3) Add 10.0 g of 98wt% concentrated sulfuric acid to the reaction solution of step (2), stir evenly to obtain a polyferric sulfate water treatment agent; detect the conversion rate of iron after the reaction, Fe 2+ converted to Fe 3+ The conversion rate reaches 99.97%; the total iron mass fraction of the polyferric sulfate water treatment agent is 11.1%.

Embodiment 2

[0030] (1) Add 50.0g FeSO 4 ·7H 2 O is mixed with 20.0g water to obtain a mixed solution;

[0031] (2) 30wt% H under normal pressure 2 o 2 15.3 g of the aqueous solution was added to the mixed solution in step (1), and the temperature was lowered while stirring, and the temperature of the solution was controlled not to exceed 40°C to obtain a reaction solution;

[0032] (3) Add 4.0g of 98wt% concentrated sulfuric acid to the reaction solution of step (2), stir evenly to obtain a polymeric ferric sulfate water treatment agent; detect the conversion rate of iron after the reaction, Fe 2+ converted to Fe 3+ The conversion rate reaches 99.96%; the total iron mass fraction of the polyferric sulfate water treatment agent is 11.3%.

Embodiment 3

[0034] (1) Add 30g FeSO 4 ·7H 2 O mixes with 15g water, obtains mixed solution;

[0035] (2) 30wt%H at normal pressure 2 o 2 Add 6.7g of the aqueous solution into the mixed solution in step (1), and carry out cooling treatment while stirring, and control the temperature of the solution not to exceed 40°C to obtain a reaction solution;

[0036] (3) Add 1.2g of 98wt% concentrated sulfuric acid to the reaction solution of step (2), stir evenly to obtain polyferric sulfate water treatment agent; detect the conversion rate of iron after the reaction, Fe 2+ converted to Fe 3+ The conversion rate reaches 99.99%; the total iron mass fraction of the polyferric sulfate water treatment agent is 11.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com