High-temperature-resistant oil-well cement retarder and preparation method thereof

A technology of oil well cement and high temperature resistance, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of unobvious fluctuations, and achieve the effect of simple and easy operation, high success rate, and increased consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

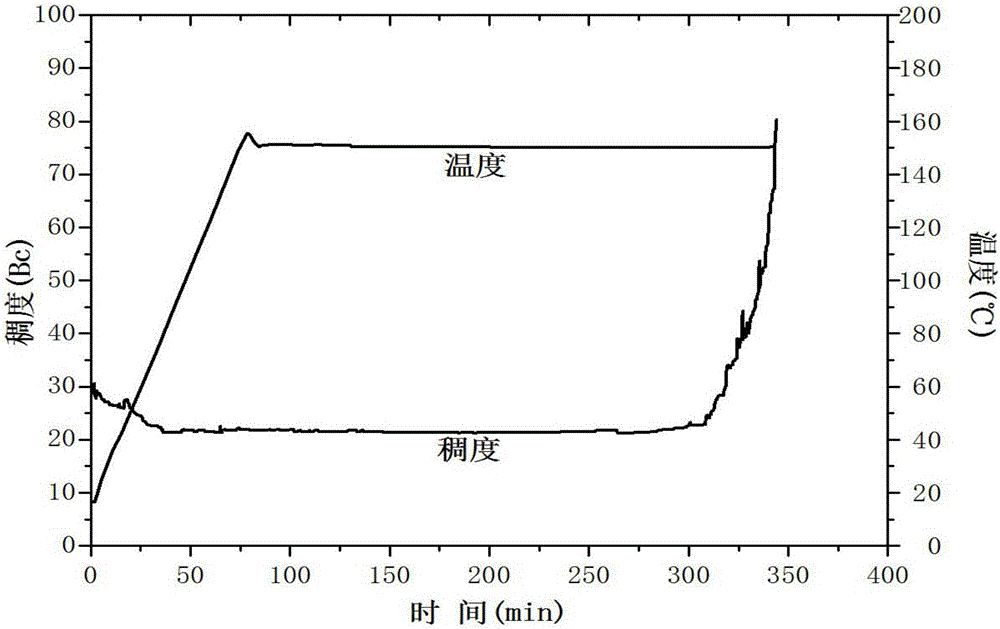

[0031] Example 1 Preparation of high temperature resistant retarder with itaconic acid as the main retarding monomer

[0032] Weigh out sodium p-styrene sulfonate (SSS), itaconic acid (IA), and N-vinyl caprolactam (NVCL) at a mass ratio of 16:3:1, and dissolve them with deionized water, and pass the concentration to 5mol / L sodium hydroxide solution to adjust the PH value to 5, with 12% solid content as the standard to control the total solution volume.

[0033] Adjust the temperature of the water bath to 60°C, and install the reaction device, which includes three-necked flask, polytetrafluoroethylene stirring rod, separatory funnel and other main components. Transfer the mixed solution of sodium styrene sulfonate (SSS) and itaconic acid (IA) into a three-necked flask, keep the PTFE stirring rod at a speed of (2000±200 rpm), and pour nitrogen into the container to remove oxygen After the temperature rises to the set temperature, use a separating funnel to add N-vinyl caprolactam (...

Embodiment 2

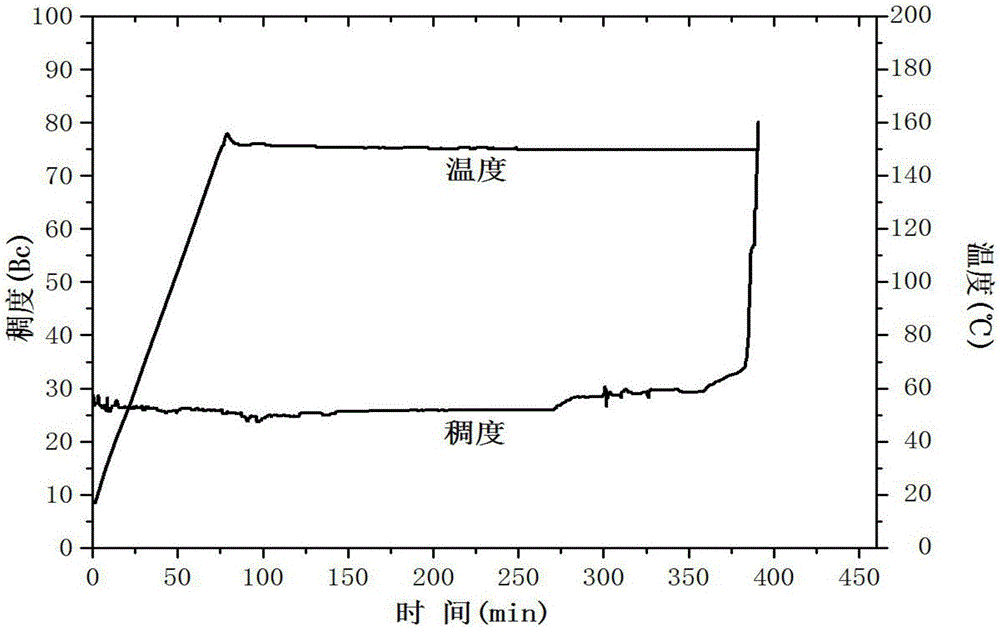

[0035] Example 2 Preparation of high temperature resistant retarder with maleic acid as the main retarding monomer

[0036] Weigh out sodium p-styrene sulfonate (SSS), itaconic acid (IA), and N-vinyl caprolactam (NVCL) in a mass ratio of 13:3:3, dissolve them with deionized water, and pass the concentration to 5mol / L of sodium hydroxide solution to adjust the PH value to 7, with 12% solid content as the standard to control the total solution volume.

[0037] Adjust the temperature of the water bath to 65°C, and install the reaction device, which includes a three-necked flask, a polytetrafluoroethylene stirring rod, a separatory funnel and other main components. Transfer the mixed solution of sodium styrene sulfonate (SSS) and itaconic acid (MA) into a three-necked flask, keep the PTFE stirring rod at (2000±200 rpm), and pour nitrogen into the container to remove oxygen After the temperature rises to the set temperature, use a separatory funnel to add N-vinylcaprolactam (NVCL) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com