Preparation method of heterogeneous cyclohexanone oxime

A cyclohexanone oxime, heterogeneous technology, applied in oxime preparation, organic chemistry and other directions, can solve the problems of high operating cost, high energy consumption, low production capacity, etc., to reduce energy consumption, reduce impurity content, and ensure efficient utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

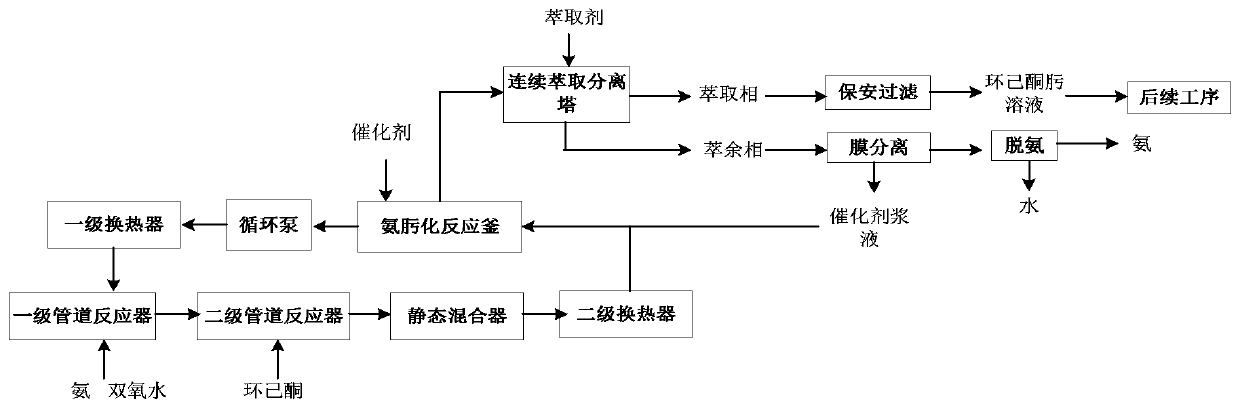

[0028] refer to figure 1 The shown process flow diagram of the present invention, a method for preparing heterogeneous cyclohexanone oxime, comprises the following steps:

[0029] (1) Ammoximation reaction

[0030] Add the titanium-silicon molecular sieve catalyst into the ammonia oximation reactor, add ammonia and hydrogen peroxide into the first-stage pipeline reactor, and add cyclohexanone into the second-level pipeline reactor. In the first-level pipeline reactor, ammonia and hydrogen peroxide are added to the catalyst Under the action of the reaction, hydroxylamine is first generated, and then reacts with the free cyclohexanone added from the secondary pipeline reactor, then circulates back to the reactor for further aging to generate cyclohexanone oxime, and obtains cyclohexanone oxime mainly containing cyclohexanone oxime, catalyst, water , a mixed solution of a small amount of ammonia; the temperature in the ammonia oximation reactor and the external circulation pipel...

Embodiment 2

[0040] refer to figure 1 The shown process flow diagram of the present invention, a method for preparing heterogeneous cyclohexanone oxime, comprises the following steps:

[0041] (1) Ammoximation reaction

[0042] The titanium-silicon molecular sieve catalyst is directly added to the ammonia oximation reactor, ammonia and hydrogen peroxide are added to the first-stage pipeline reactor, and cyclohexanone is added to the second-level pipeline reactor. In the first-level pipeline reactor, ammonia and hydrogen peroxide are Under the action of the catalyst, hydroxylamine is first generated, and then reacts with the free cyclohexanone added from the secondary pipeline reactor, then circulates back to the reactor for further aging to generate cyclohexanone oxime, and obtains cyclohexanone oxime mainly containing cyclohexanone oxime, catalyst, A mixed solution of water and a small amount of ammonia; the temperature in the ammonia oximation reactor and the external circulation pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com