Oxygenation method and oxygenation device for high pressure casting

A high-pressure casting and high-pressure technology, which is applied in the field of high-pressure casting oxygenation and its oxygenation device, can solve the problem of unequal control of oxygenation time and rhythm, and achieve the effect of simple structure and low oxygen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

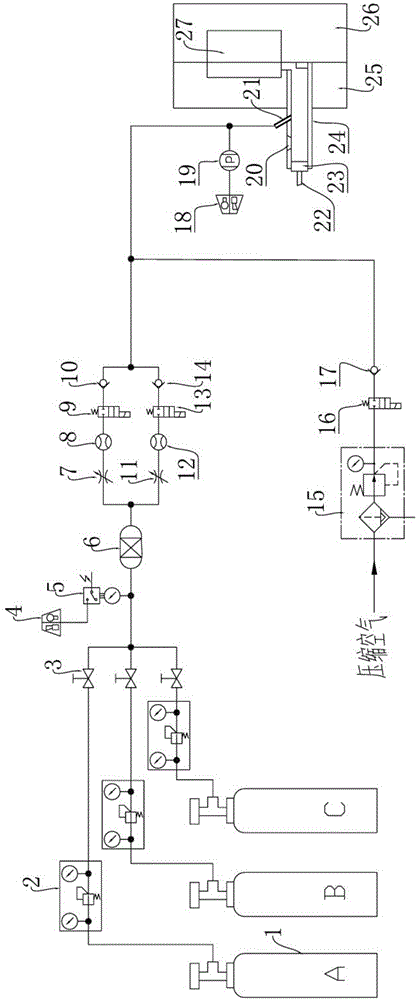

[0023] The oxygenation method and the oxygenation device of the high pressure casting applying the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] like figure 1 As shown, the high-pressure casting system includes a casting press, and the casting press includes a pressure chamber 24, and the pressure chamber 24 communicates with a mold cavity 27; the mold includes a fixed mold 25 and a movable mold 26.

[0025] The left side of the pressure chamber 24 is provided with an extruding piston 23 , and the right side is provided with an air inlet pipe 21 , and a gate 20 through which liquid metal enters is arranged between the air inlet pipe 21 and the extruding piston 23 . The drive shaft 22 of the extrusion piston 23 is connected to a drive cylinder (not shown in the figure). When the metal liquid is poured from the gate 20 into the pressure chamber 24, the metal liquid can flow into the mold cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com