Heat recovering technique for synthetic gas production process by coal gasification

A technology of heat recovery and process method, applied in the chemical industry, sustainable manufacturing/processing, petroleum industry, etc., can solve the problems of reducing the heat transfer efficiency of radiant coolers, improve the utilization value, expand the scope of application, and reduce consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

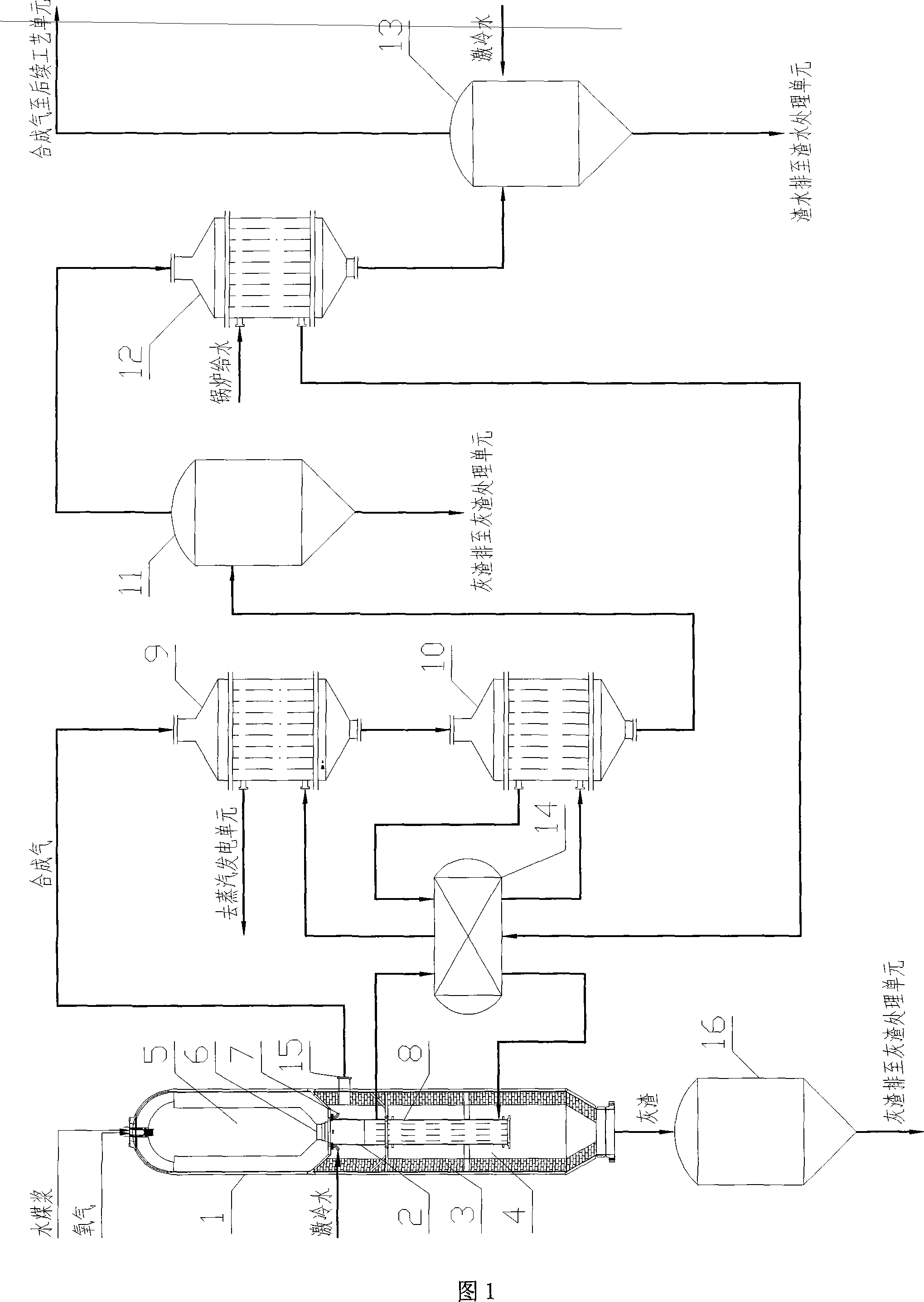

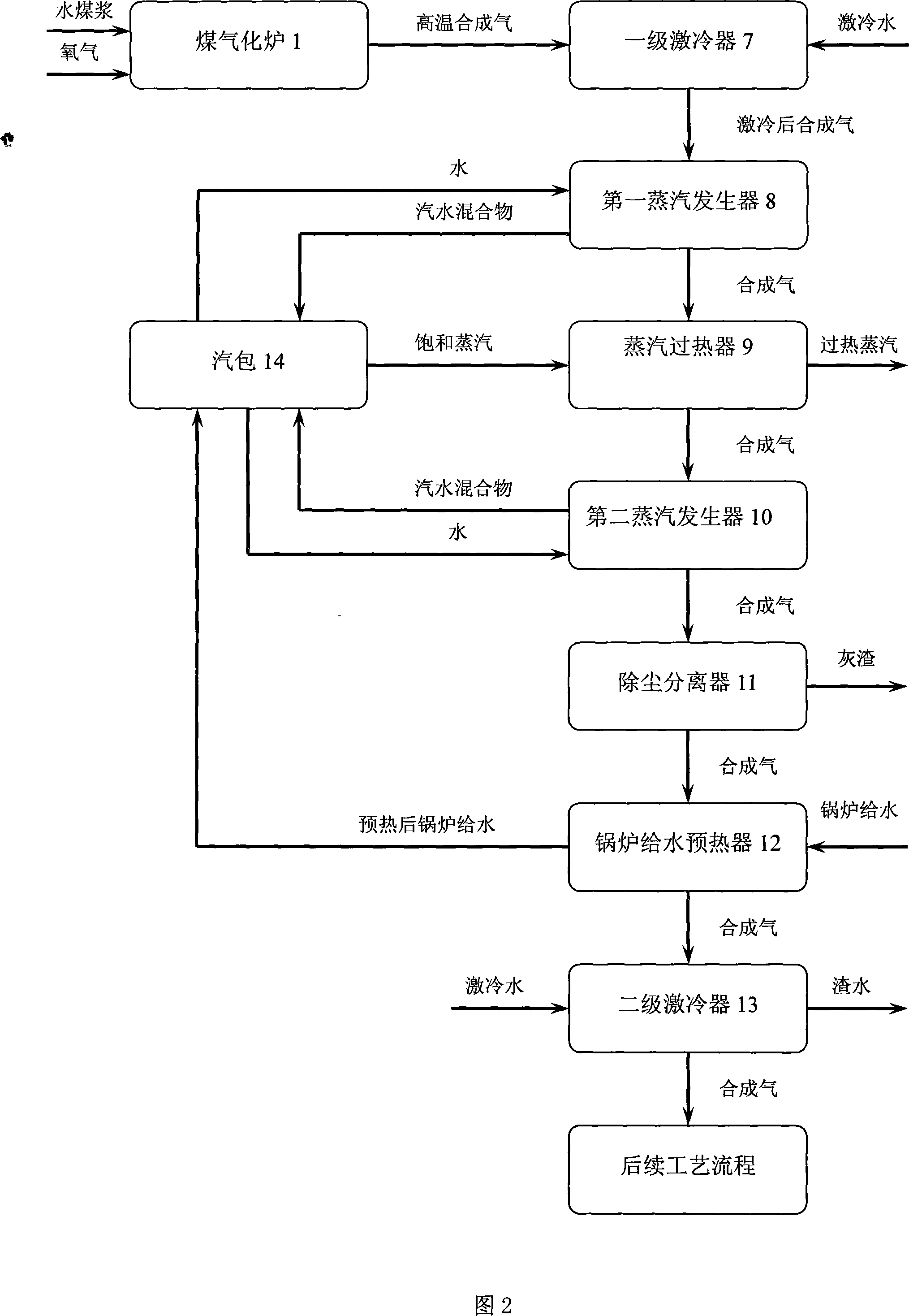

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] Taking a gasification furnace with a coal processing capacity of 35 tons / hour as an example, referring to Fig. 1, the coal gasification furnace 1 of the device is provided with a gasification chamber 5 and a quenching chamber 4; in the transition connection between the gasification chamber and the quenching chamber The section is provided with a first-stage chiller 7, and the first-stage chiller 7 is composed of 20 atomizing nozzles. The synthesis gas produced by the gasification chamber 5 has a pressure of 6.5MPa and a temperature of 1250-1350°C. It enters the primary chiller 7 from the outlet 6 of the gasification chamber, and the primary chiller 7 sprays chilled water into the In the stream of synthesis gas, this can make the synthesis gas be cooled uniformly and rapidly, so as to avoid the agglomeration of slag. The gas and ash go down the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com