Biochemical sludge processing method

A biochemical sludge and treatment method technology, applied in pyrolysis treatment of sludge and other directions, can solve problems such as unsuitable land use, occupy large land, damage the environment, etc., achieve good economic and social benefits, reduce equipment investment, save energy effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

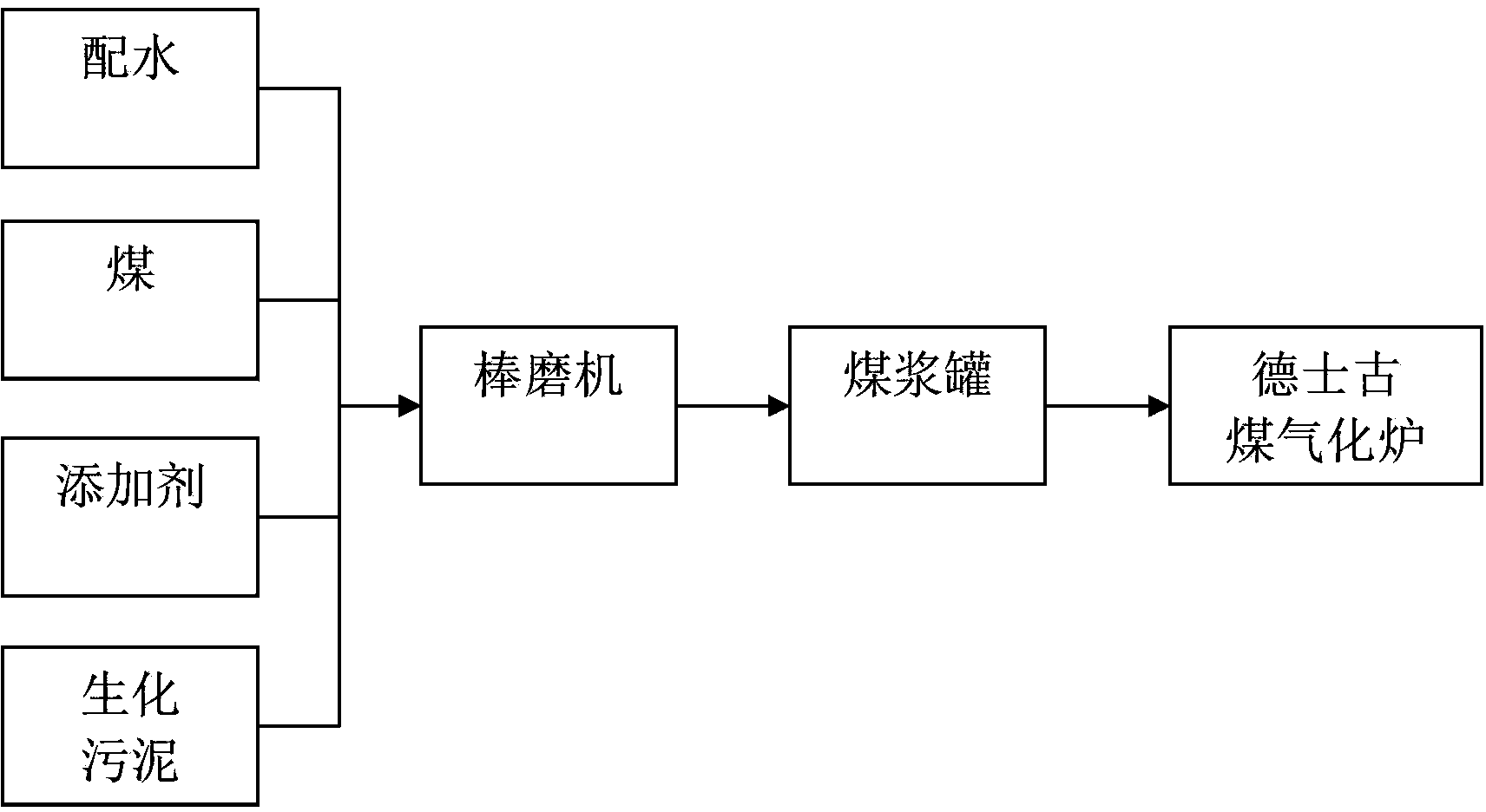

Method used

Image

Examples

Embodiment 1

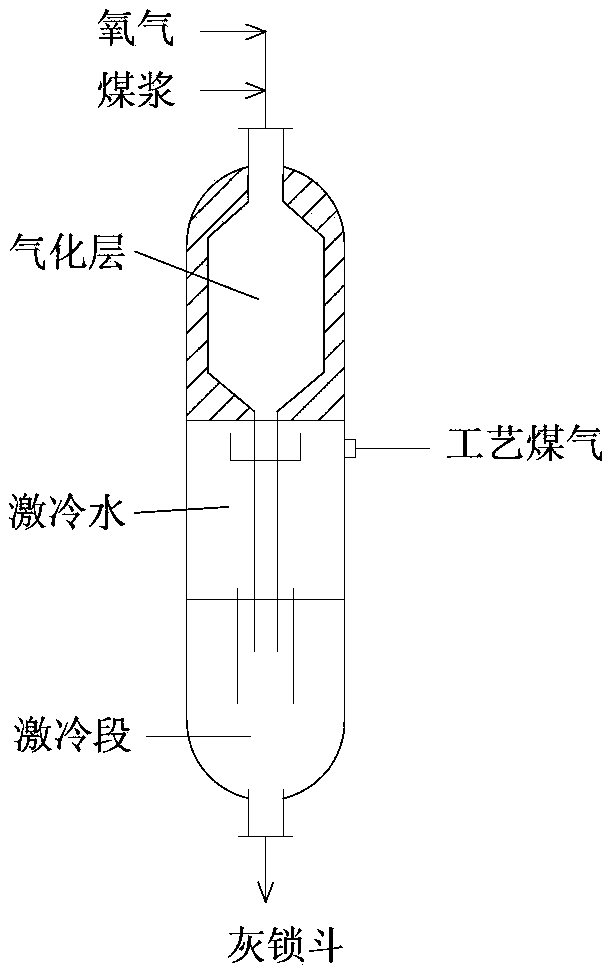

[0050] Example 1: 70 parts of coal, 0.5 part of biochemical sludge with a water content of 75%, 30 parts of cyclohexanone wastewater and 0.5 part of lignosulfonate are added to a rod mill according to the mass ratio, and the rod mill forms water coal Slurry, coal water slurry viscosity in 700 ~ 1400mPa. Between S, in line with the process requirements. Pump the prepared coal-water slurry to the coal slurry tank for storage, and use the diaphragm pump to transport the coal-water slurry in the coal slurry tank to the raw material inlet of the Texaco coal gasifier. The oxygen-coal ratio is 480, and the coal-water slurry And oxygen enters the gasification layer of the Texaco coal gasifier, gasifies at 1350°C to generate process gas and produces slag, and the sludge in the coal-water slurry is completely gasified at 1350°C. After the process gas enters the quenching section, it is discharged from the process gas outlet, and hydrogen is obtained through the subsequent purification ...

Embodiment 2

[0051] Example 2: 60 parts of coal, 5 parts of biochemical sludge with a water content of 85%, 40 parts of nitrobenzene wastewater and 1 part of humate are added to the rod mill according to the mass ratio, and the rod mill forms a coal-water slurry , CWS viscosity in 700 ~ 1400mPa. Between S, in line with the process requirements. The prepared coal water slurry is pumped to the coal slurry tank for storage, and the diaphragm pump is used to transport the coal water slurry in the coal slurry tank to the raw material inlet of the Texaco coal gasifier, and the coal water slurry and oxygen enter the Texaco The gasification layer of the coal gasification furnace, with an oxygen-to-coal ratio of 500, is gasified at 1400°C to generate process gas and slag, and the sludge in the coal-water slurry is completely gasified at 1400°C. After the process gas enters the quenching section, it is discharged from the process gas outlet, and hydrogen is obtained through the subsequent purificat...

Embodiment 3

[0052] Example 3: 65 parts of coal, 3 parts of biochemical sludge with a water content of 80%, 35 parts of nitrochlorobenzene waste water and 0.1 part of naphthalenesulfonic acid formaldehyde condensate are added to the rod mill according to the mass ratio, and the rod mill forms Coal water slurry, the viscosity of coal water slurry is 700~1400mPa. Between S, in line with the process requirements. The prepared coal water slurry is pumped to the coal slurry tank for storage, and the diaphragm pump is used to transport the coal water slurry in the coal slurry tank to the raw material inlet of the Texaco coal gasifier, and the coal water slurry and oxygen enter the Texaco The gasification layer of the coal gasifier has an oxygen-to-coal ratio of 490. It is gasified at 1380°C to generate process gas and slag. The sludge in the coal-water slurry is completely gasified at 1380°C. After the process gas enters the quenching section, it is discharged from the process gas outlet, and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com