Coal gasification-to-synthesis gas and chemical chain-to-oxygen-hydrogen combined cycle apparatus and coal gasification-to-synthesis gas and chemical chain-to-oxygen-hydrogen combined cycle method

A combined cycle, coal gasification technology, applied in chemical instruments and methods, oxygen/ozone/oxide/hydroxide, gasification processes, etc., can solve the problems of aggravating the global greenhouse effect, low hydrogen production efficiency, and complex processes , to achieve the effect of reducing CO2 emissions, simple process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

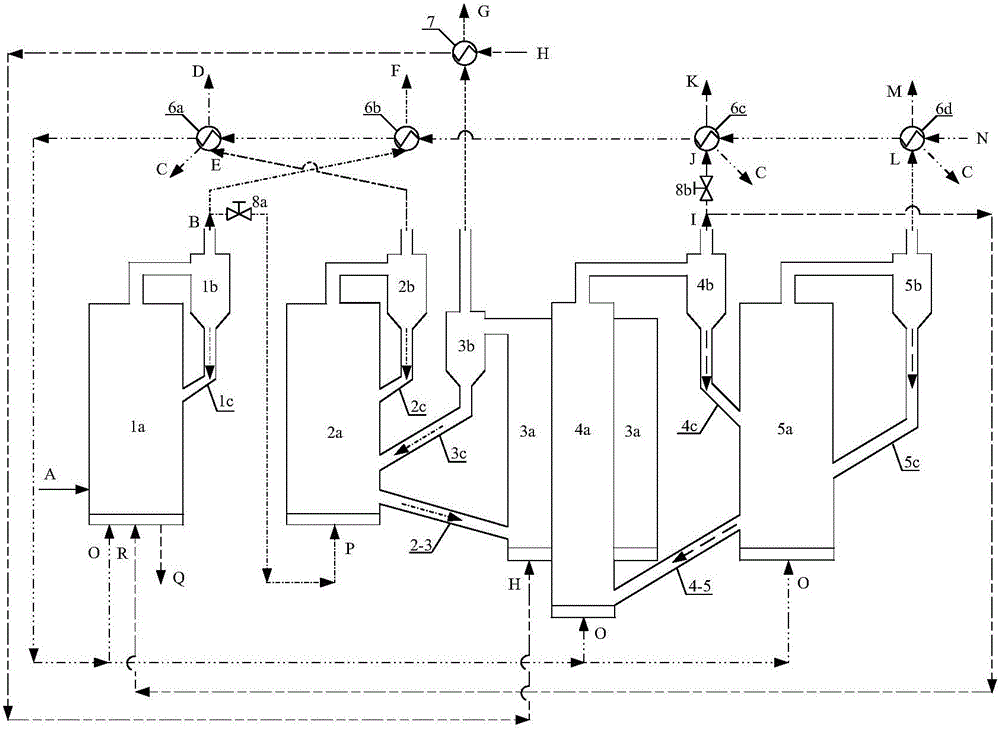

[0028] like figure 1 As shown, a coal gasification synthesis gas and chemical looping oxygen-hydrogen production combined cycle device includes a coal gasifier 1, a chemical looping combustion unit, a chemical looping oxygen-hydrogen production unit, a heat exchanger and pipelines;

[0029] The coal gasification furnace 1 is composed of a coal gasification furnace body 1a, a coal gasification furnace corresponding cyclone separator 1b and a coal gasification furnace corresponding standpipe 1c. The vertical pipe 1c corresponding to the furnace is connected to the main body 1a of the coal gasifier, and the upper outlet pipeline corresponding to the cyclone separator 1b of the coal gasifier is divided into two, one is connected to the second heat exchanger 6b, and the other is connected to the first switch control valve 8a and The fuel reactor body 2a is connected; the coal gasifier body 1a uses various bed forms, including moving bed, fluidized bed and entrained flow bed.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com