Dry coal dust gasification furnace for carbon dioxide emission reduction

A carbon dioxide and gasifier technology, applied in the direction of granular/powdered fuel gasification, reagents, educts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

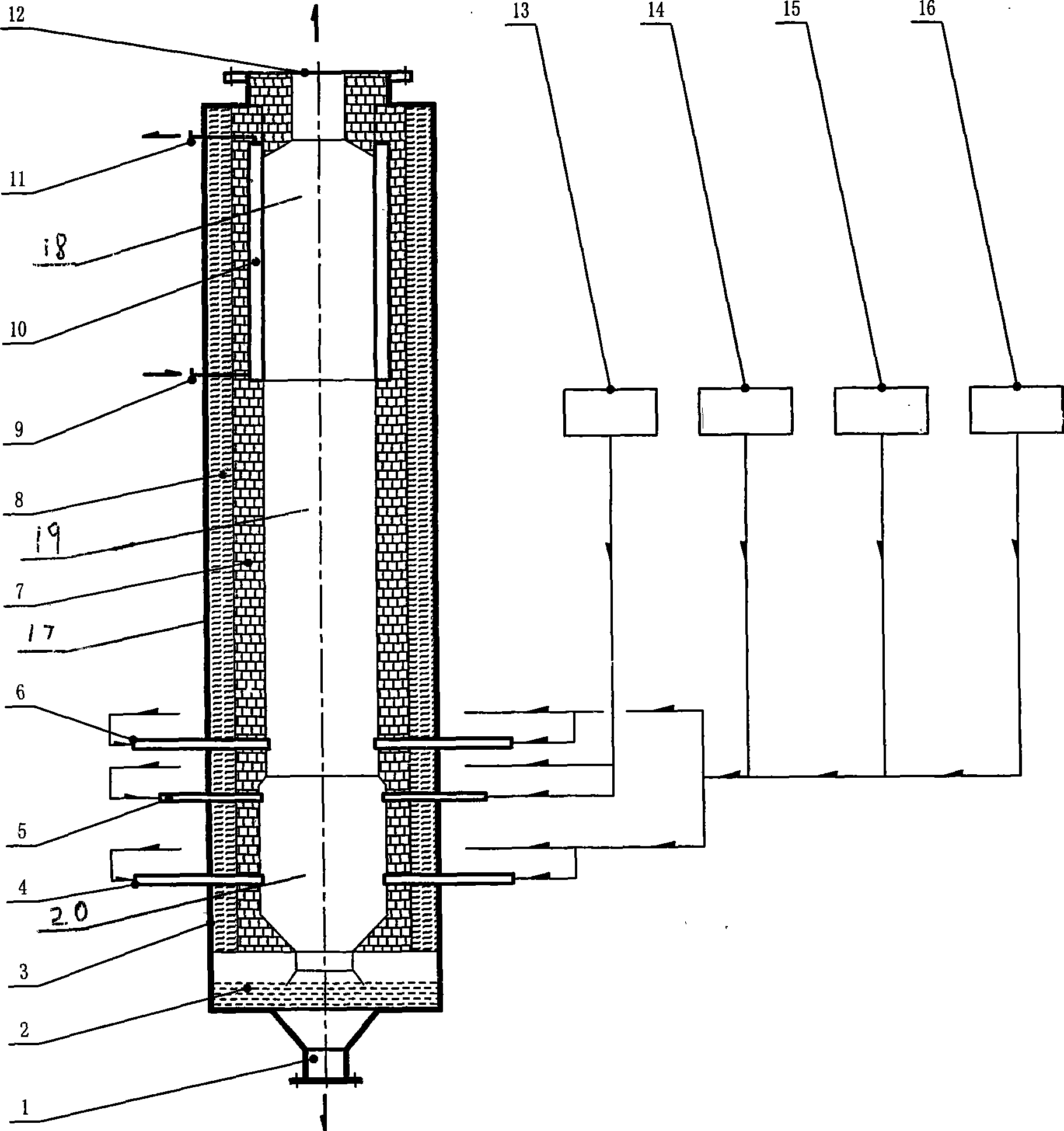

[0011] 17 among the figure is the gasification furnace of the present invention, and gasification furnace 17 is made up of shell 3, coal gas outlet 12, slag outlet 1 and feed port 4, feed port 5, feed port 6, and shell 3 lining Insulation material 8 and refractory material 7, the lower part of the shell 3 is the slag outlet 1 and the water seal 2, and the interior can be divided into three areas, from top to bottom are the cooling area 18, the reduction area 19, the combustion area 20, and the cooling area The inner wall of the housing 3 of 18 is lined with a water jacket 10, and the water jacket 10 has a water inlet 9 and a water outlet 11. In the lower part of the housing 3, there are a primary feed port 4, a secondary feed port 6, and a feed port It is connected with the feeding device, which is composed of a carbon dioxide storage tank 13, a pulverized coal storage tank 14, an oxygen storage tank 15, and a steam storage tank 16 to supply raw materials for the gasifier. The...

Embodiment 2

[0013] According to Embodiment 1, in order to ensure the supply of carbon dioxide and the stability and easy control of production, a special carbon dioxide feed port 5 can be set, which is communicated with the carbon dioxide storage tank 13 separately, and the primary feed port 4 and the secondary feed port 6 are connected to the carbon dioxide storage tank 13. Other storage tanks are connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com