Efficient coal dust combustor for reducing smoke NOx content

A burner and content technology, applied in the direction of burners, burners burning powder fuel, combustion methods, etc., can solve the problems of inapplicability to small and medium-sized pulverized coal boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

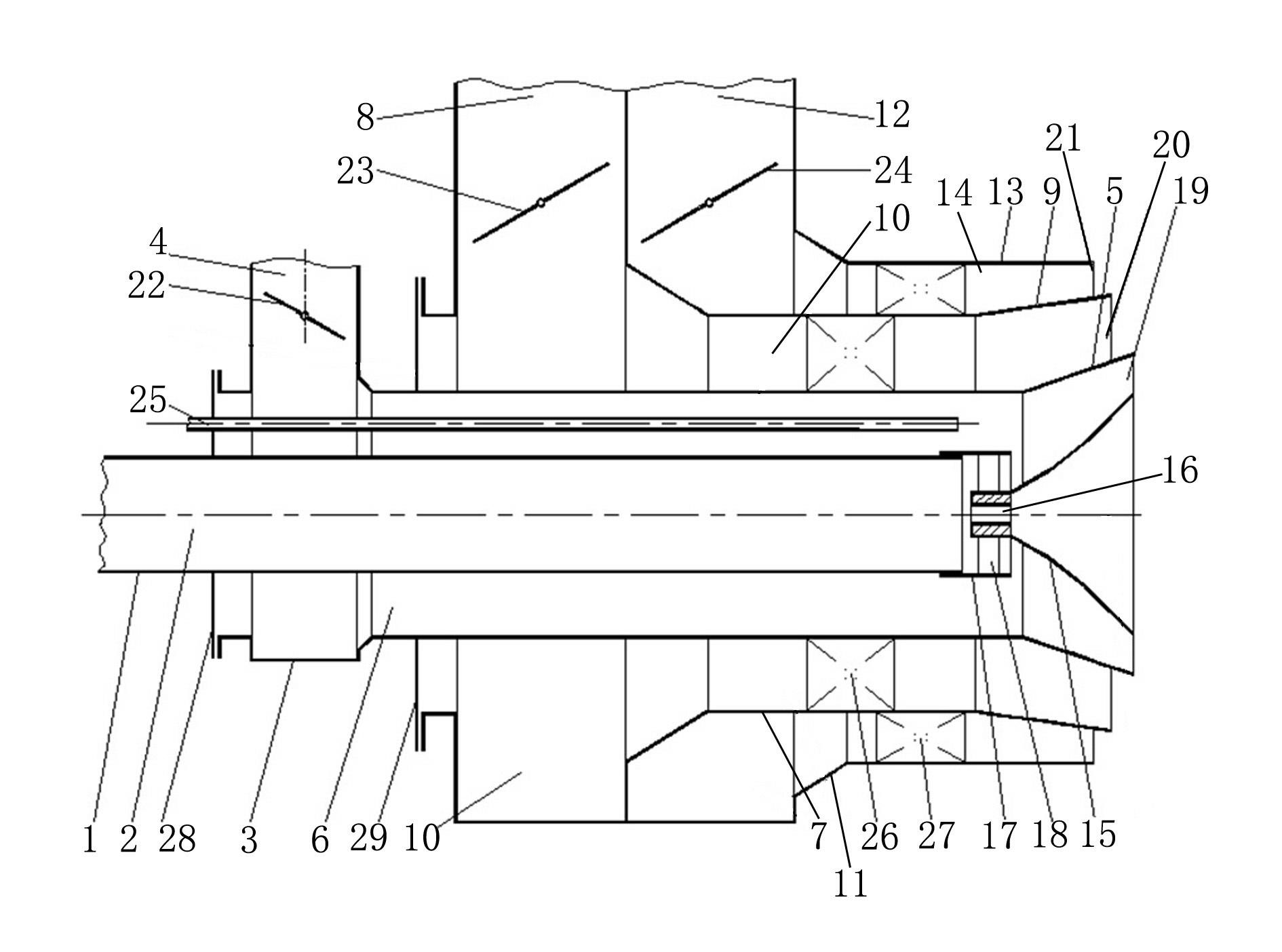

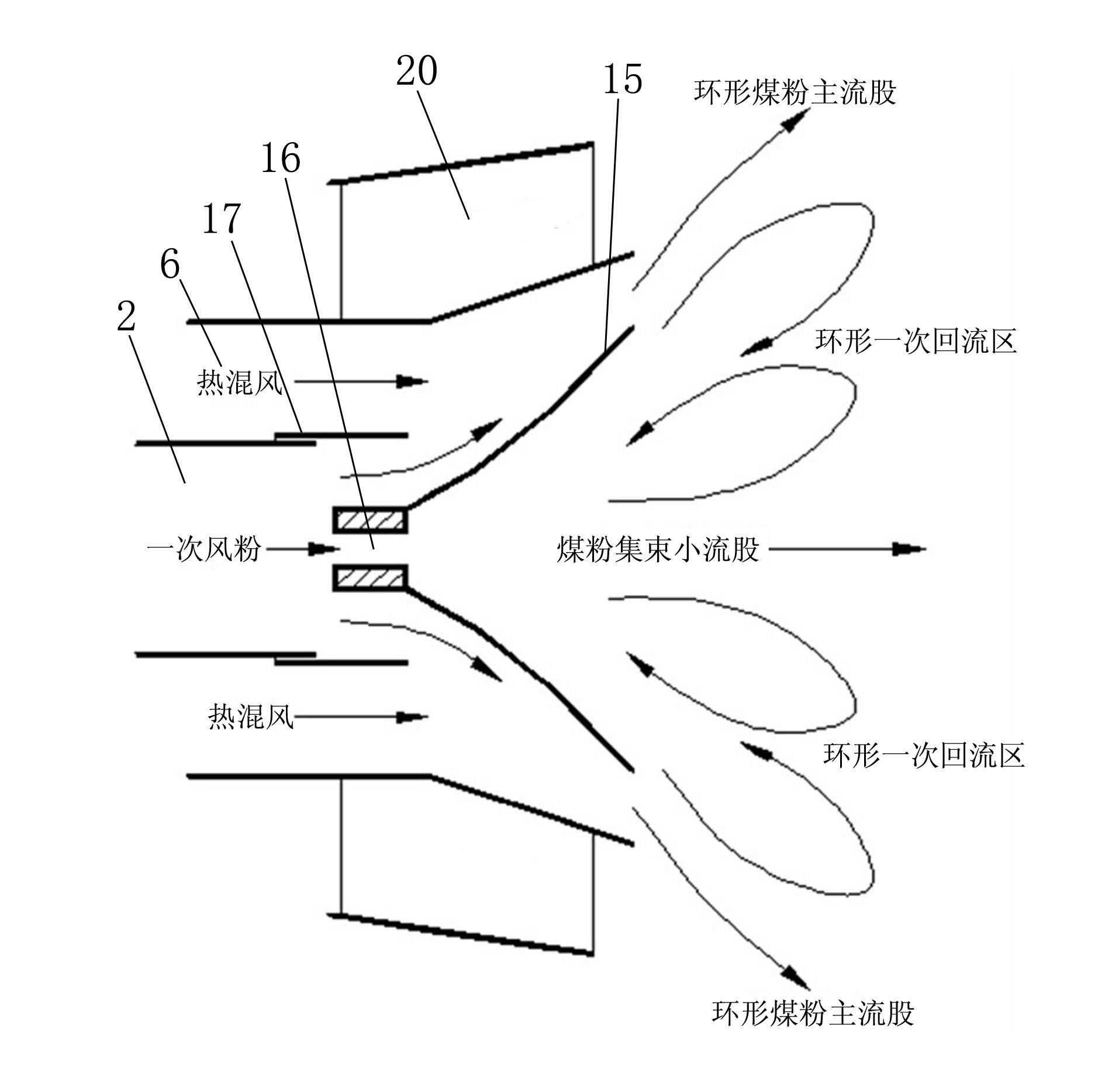

[0017]The high-efficiency pulverized coal burner for reducing the NOx content of flue gas includes a primary air duct 1; the inner cavity of the primary air duct 1 forms a primary air channel 2; the outer coaxial sleeve of the primary air duct 1 is provided with an air mixing sleeve 3; the air mixing sleeve The inlet end of the tube 3 is connected with the mixed air inlet pipe 4; the outlet end of the mixed air sleeve 3 is provided with a mixed air expansion section 5; the inner wall of the mixed air sleeve 3 and the outer wall of the primary air pipe 1 jointly form an annular mixed air chamber 6 The outer coaxial sleeve of the air mixing sleeve 3 is provided with an inner secondary air sleeve 7; the inlet end of the inner secondary air sleeve 7 is connected with an inner secondary air inlet pipe 8; the outlet of the inner secondary air sleeve 7 The end is provided with an inner secondary air expansion section 9; the inner wall of the inner secondary air sleeve 7 and the outer ...

Embodiment 2

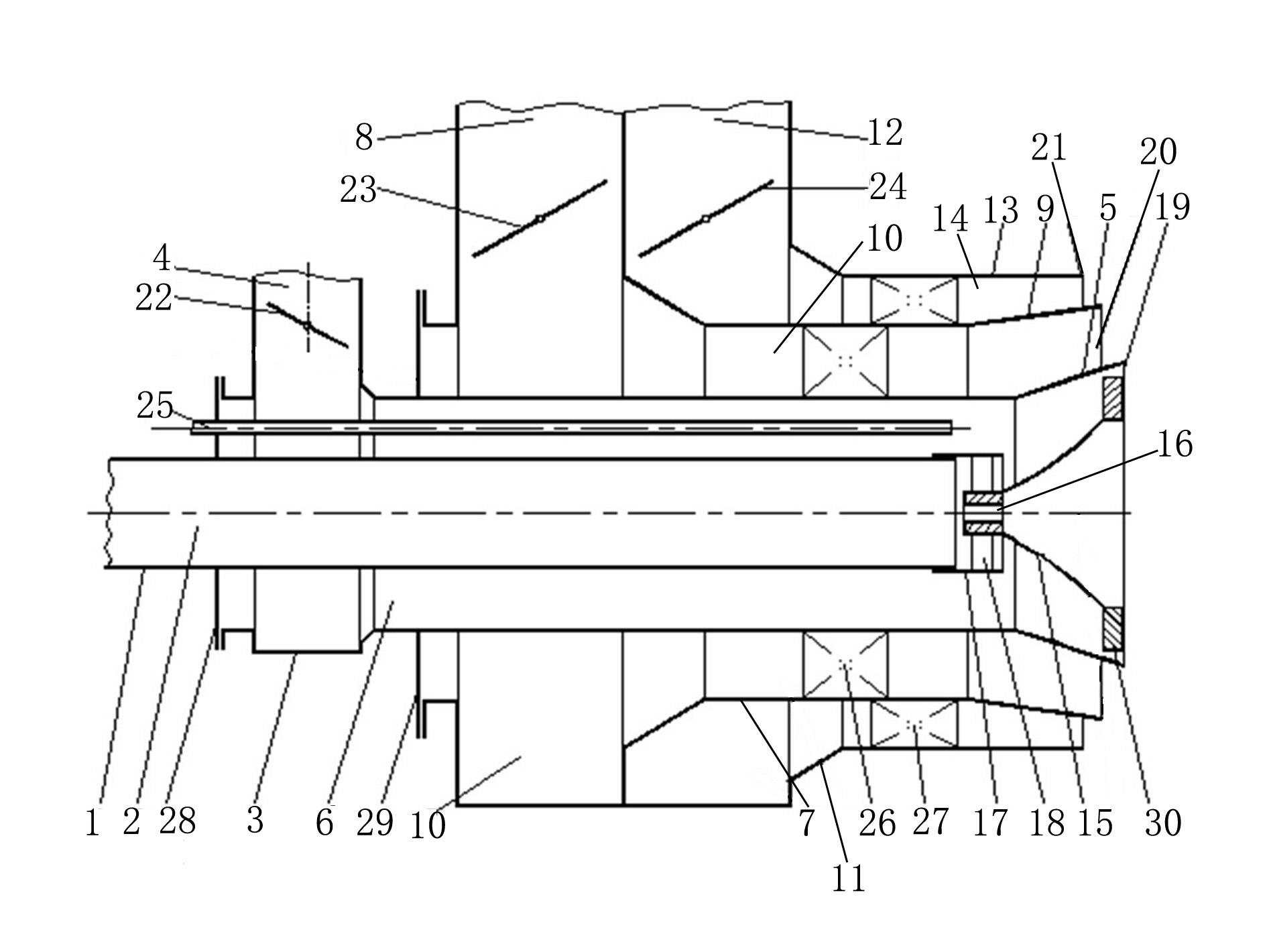

[0022] The high-efficiency pulverized coal burner for reducing the NOx content of flue gas includes a primary air duct 1; the inner cavity of the primary air duct 1 forms a primary air channel 2; the outer coaxial sleeve of the primary air duct 1 is provided with an air mixing sleeve 3; the air mixing sleeve The inlet end of the tube 3 is connected with the mixed air inlet pipe 4; the outlet end of the mixed air sleeve 3 is provided with a mixed air expansion section 5; the inner wall of the mixed air sleeve 3 and the outer wall of the primary air pipe 1 jointly form an annular mixed air chamber 6 The outer coaxial sleeve of the air mixing sleeve 3 is provided with an inner secondary air sleeve 7; the inlet end of the inner secondary air sleeve 7 is connected with an inner secondary air inlet pipe 8; the outlet of the inner secondary air sleeve 7 The end is provided with an inner secondary air expansion section 9; the inner wall of the inner secondary air sleeve 7 and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com