Control method for coal gasifier

A control method and technology of coal gasification, which can be used in granular/powder fuel gasification, special data processing applications, instruments, etc., can solve the problems of difficulty, large and complex equipment, and high temperature in the furnace, and achieve the effect of precise adjustment and monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

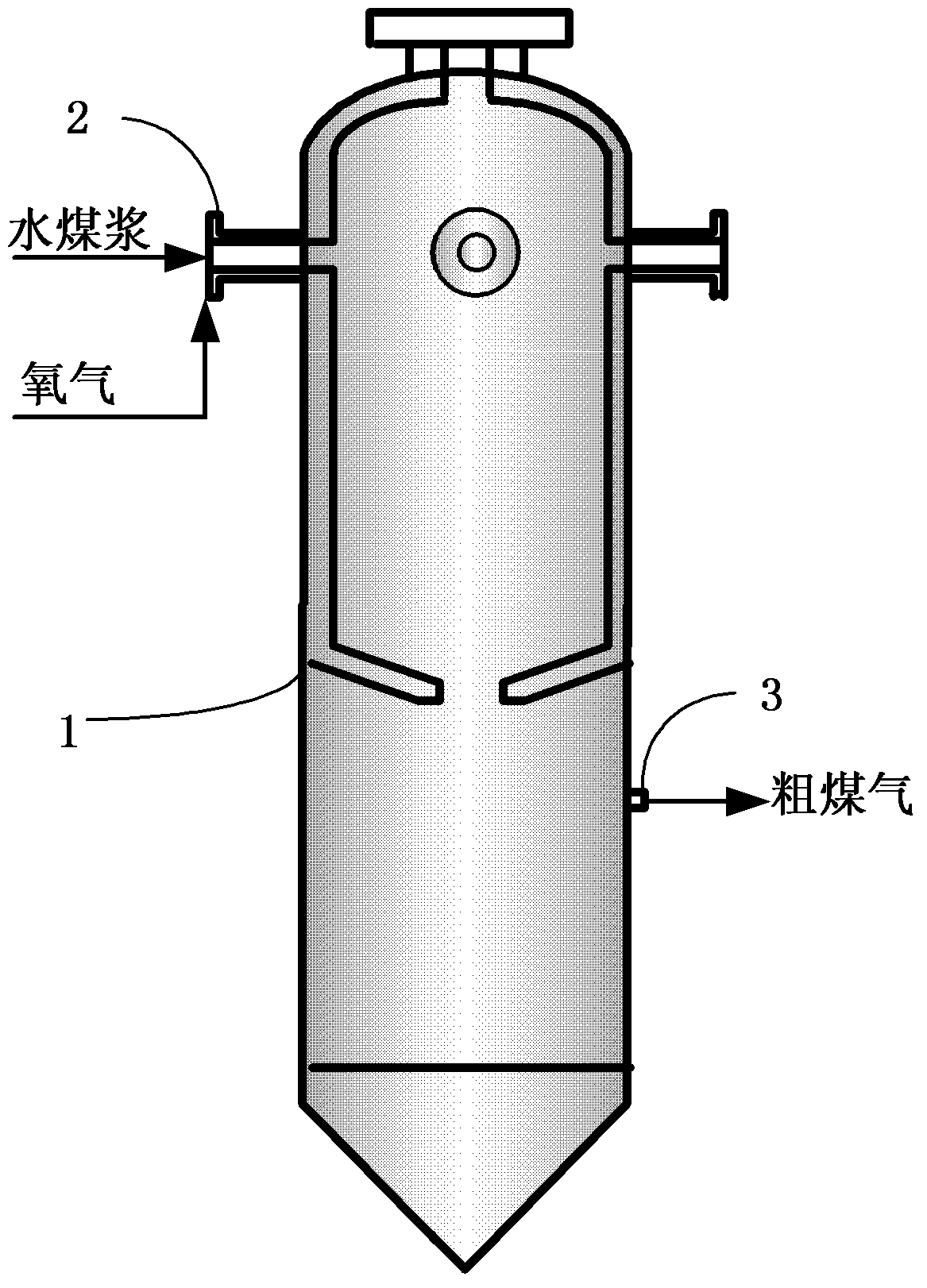

[0014] figure 1 It is a schematic diagram of the structure of a coal gasifier. As shown in the figure, the coal gasifier 1 includes a feed port 2 and a gas outlet 3. After the coal water slurry and oxygen enter the coal gasifier 1 from the feed port 2, they undergo a series of complex chemical reactions at a certain temperature and pressure. , generate CO, CO 2 、H 2 The crude gas as the main component is discharged from the gas outlet 3. It should be noted that the figure 1 It is only a schematic diagram. The actual coal gasifier also includes other various working parts, such as slag outlet, etc., but they are all well known to those skilled in the art and do not affect the control method of the present invention, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com