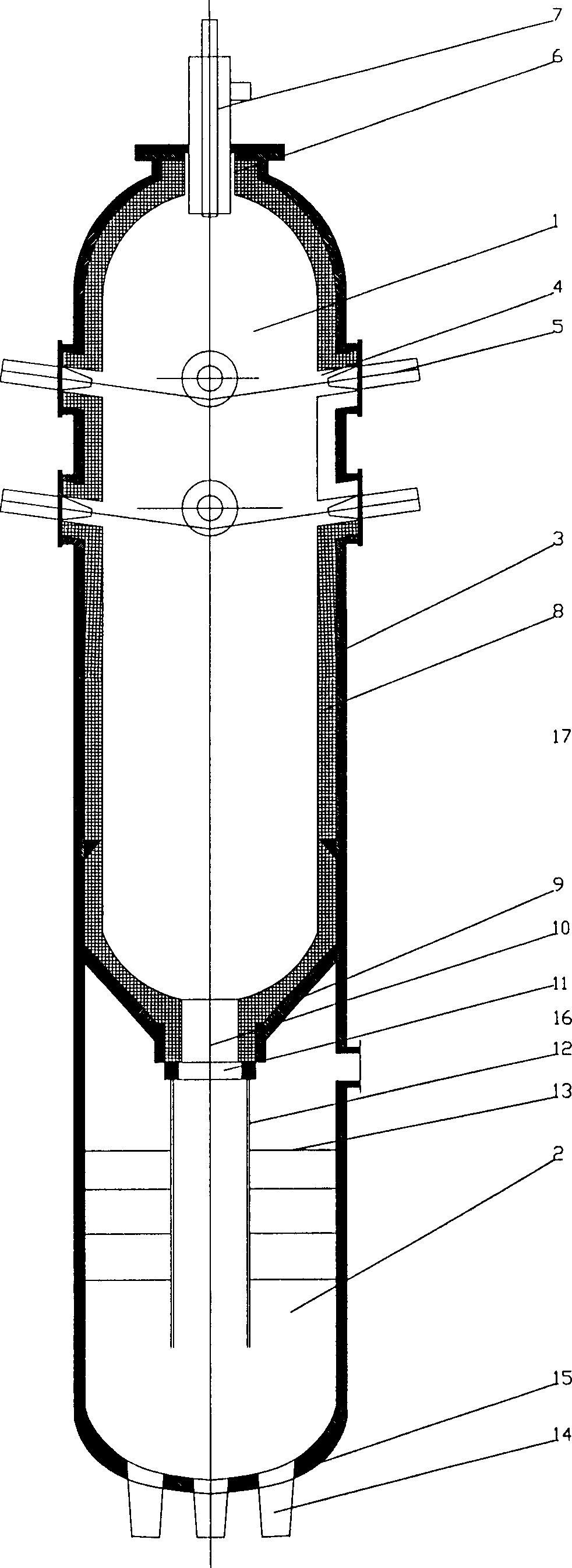

Multi-nozzle coal water mixture or fine coal gasifying furnace and its industrial application

A coal-water slurry and multi-nozzle technology, applied in the field of gasifier, can solve the problems of easy solidification, shortened operation period, easy blockage of pipelines and downstream equipment, etc., and achieves the effect of saving investment and uniform temperature distribution in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A multi-nozzle coal-water slurry gasifier with a daily processing capacity of 3,000 tons of coal, the gasification pressure is 6.5MPa, the inner diameter of the gasification chamber shell is Φ4400mm, and there are three slag lowering ports 14. The coal-water slurry process nozzle adopts the patent 95111750.5 For the proposed structure, the angle α between the axis and the horizontal plane is 10°;

[0024] The gasifying agent is oxygen, and the total consumption of oxygen is 82192Nm 3 / h, the gasification temperature is 1350°C, the weight ratio of coal water slurry to gasification agent is 1.77, and the total gas flow rate out of the gasification chamber is 301476Nm 3 / h.

[0025] Calorific value (kJ / kg)

[0026] h 2

Embodiment 2

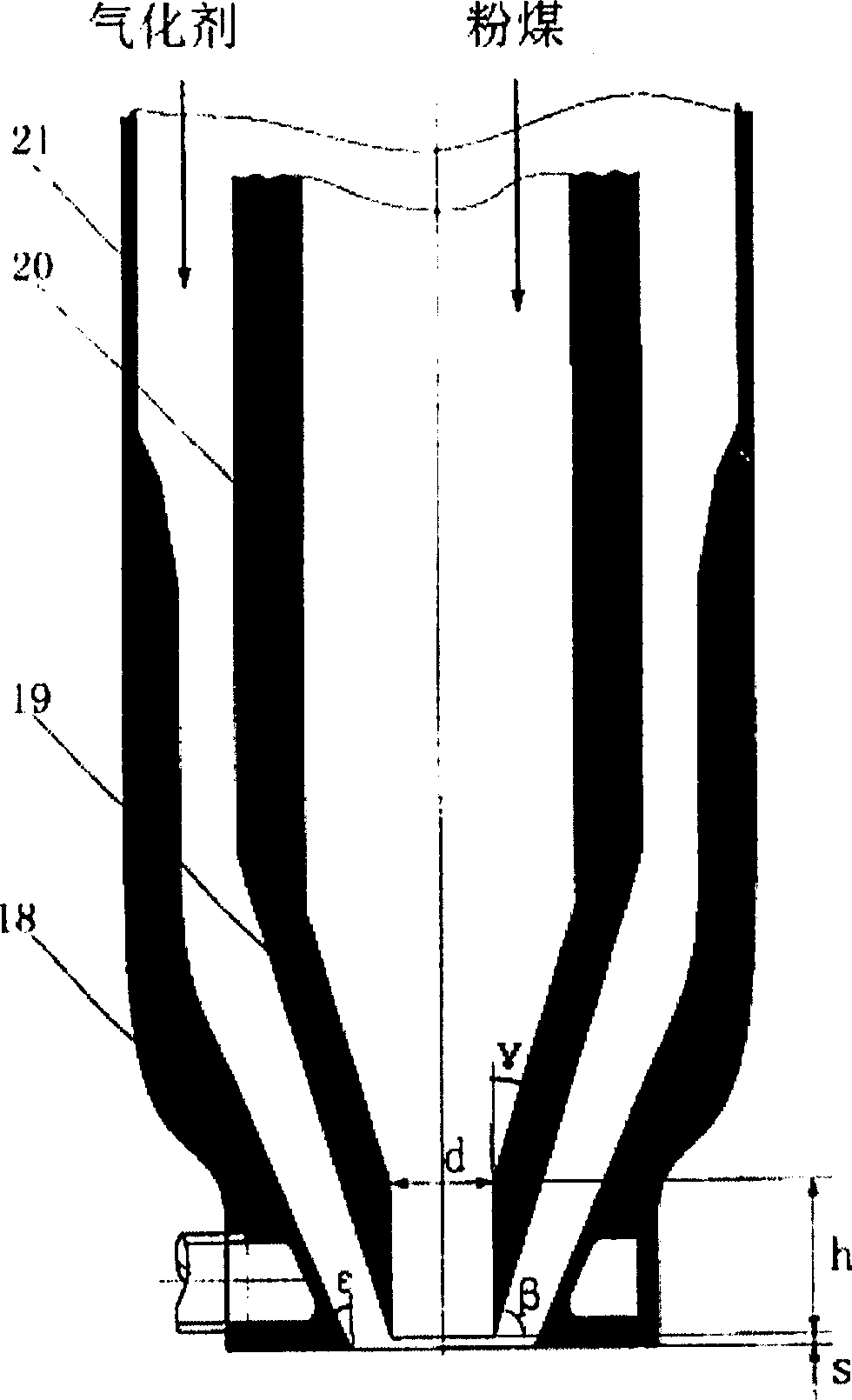

[0028] A multi-nozzle pulverized coal gasifier with a daily processing capacity of 3,000 tons of coal, the gasification pressure is 4.0MPa, the inner diameter of the gasification chamber shell is Φ4200mm, and there are three slag lowering ports 14, and the nozzle adopts figure 2 structure, the angle α between the axis and the horizontal plane is 10°;

[0029] The gasification agent is oxygen and water vapor, and the total consumption of oxygen is 70000Nm 3 / h, the total steam consumption is 22500kg / h, the gasification temperature is 1350°C, the weight ratio of pulverized coal to oxygen is 1.25, and the total gas flow out of the gasification chamber is 264175Nm 3 / h.

[0030] Water (wt%)

[0031] h 2 (v)%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com