Underground coal gasification furnace and underground coal gasification method

a gasification furnace and underground coal technology, applied in the direction of surface mining, wellbore/well accessories, construction, etc., can solve the problems of poor directivity of air fracturing drilling blockage, etc., to eliminate the defects in the gasification production stage, slow penetration speed, and unstable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0048]The underground coal gasification furnace and the underground coal gasification process according to the present invention are explained by taking bituminous coal seam having buried depth of 500 m and horizontal thickness of 10 m at some place as an example.

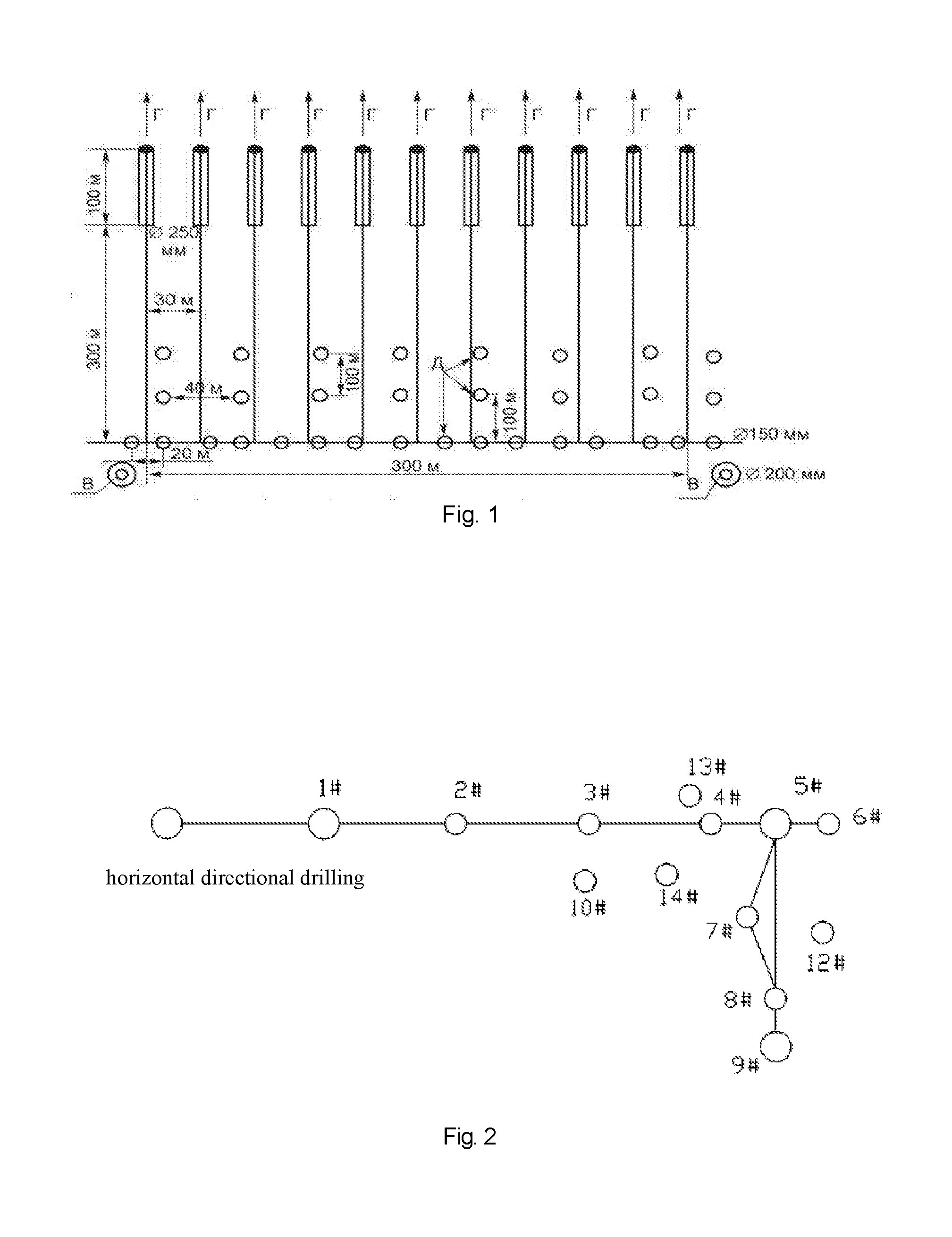

[0049]Firstly, referring to FIG. 4, a first vertical drilling well 1 is drilled to the middle lower part of the coal seam in the selected area for constructing the underground gasification furnace; the first horizontal directional drilling well a is drilled against the developing direction of cracks in coal seam towards the first vertical drilling well 1; the first horizontal directional drilling well a has a 250 m horizontal bore hole at the middle lower part of the coal seam. The second vertical drilling wells 2-7 are drilled into the middle lower part of the coal seam at a distance of about 5 m from both sides of the first horizontal directional drilling well a, which are spaced from each other at a distance of 25 m. The...

example 2

[0055]The underground coal gasification furnace and the underground coal gasification process according to the present invention are explained by taking lignite coal seam having buried depth of 300 m and horizontal thickness of 8 m at some place as an example.

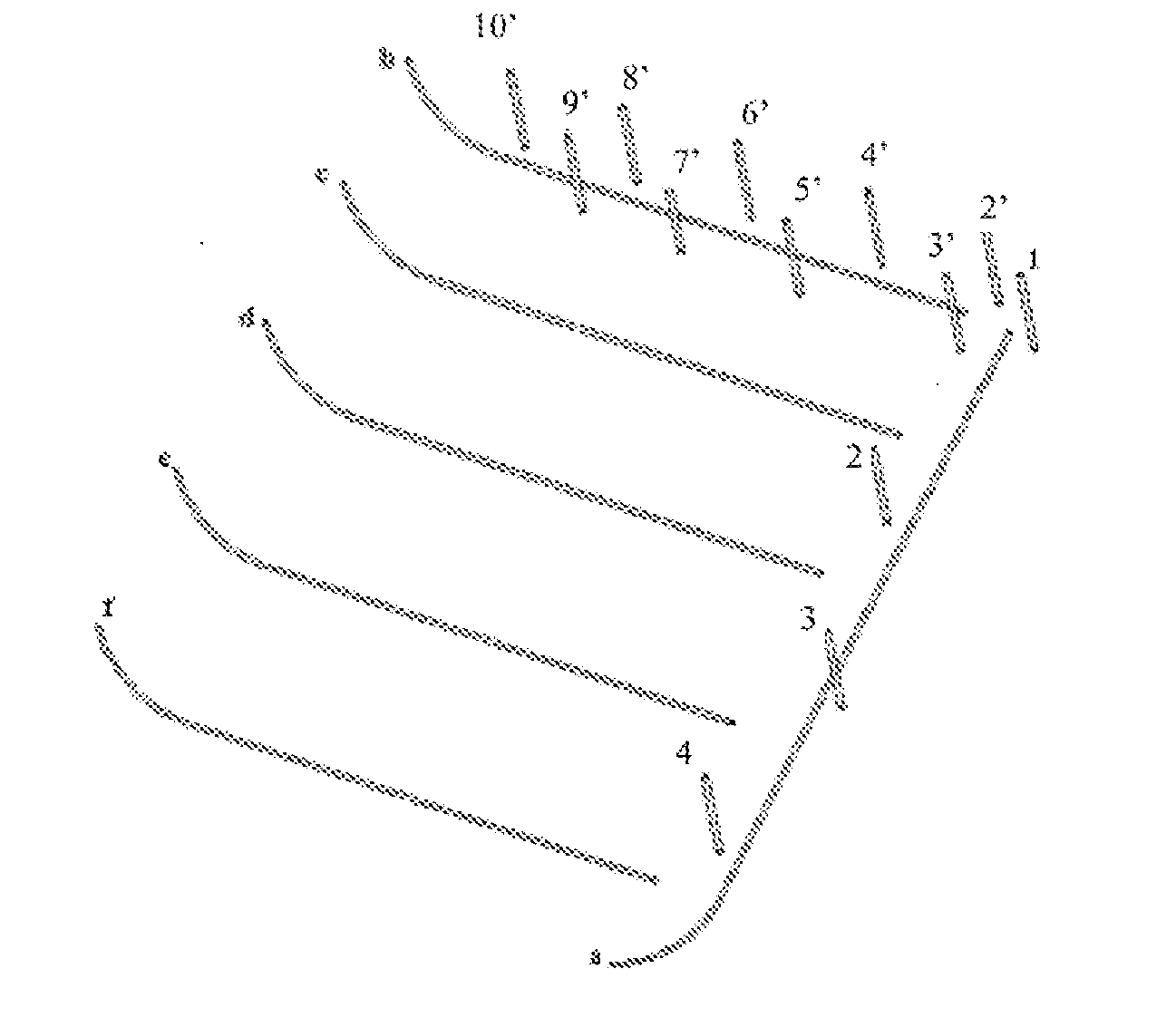

[0056]Firstly, the developing direction of cracks in coal seam is determined according to geological data in the selected coal seam area for underground gasification, as shown by arrow in FIG. 5. At one selected point, a first vertical drilling well 1 is drilled to the middle lower part of the coal seam; a second vertical drilling well is drilled into the middle lower part of the coal seam in the developing direction of cracks in coal seam at interval of about 35 m and is numbered as 2, 3, 4, 5, 6; the first horizontal directional drilling well a is drilled against the developing direction of cracks in coal seam towards the first vertical drilling well 1; the horizontal section of the drilling well has a length of about 250 m a...

example 3

[0060]The underground coal gasification furnace and the underground coal gasification process according to the present invention are explained by taking sub-bituminous coal seam having buried depth of 600 m and horizontal thickness of 12 m at some place as an example.

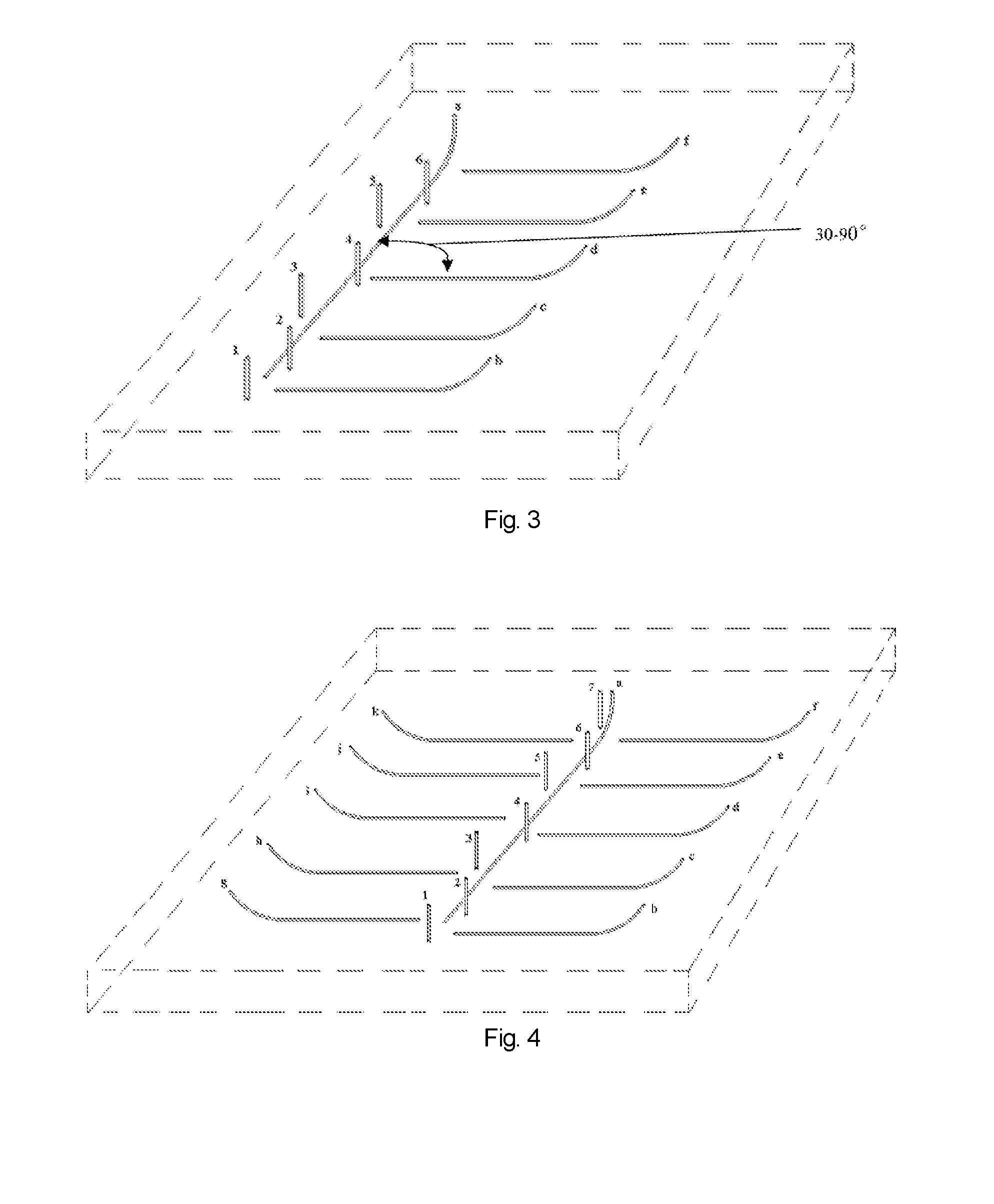

[0061]Firstly, referring to FIG. 6, a first vertical drilling well 1 is drilled to the middle lower part of the coal seam in the selected area for constructing the underground gasification furnace; the first horizontal directional drilling well a is drilled against the developing direction of cracks in coal seam towards the first vertical drilling well 1; the first horizontal directional drilling well a has a horizontal bore hole with a length of 250 m at the middle lower part of the coal seam. The second vertical drilling wells 2-3 are drilled into the middle lower part of the coal seam at a distance of 5-15 m from one side of the first horizontal directional drilling well a at intervals of about 100 m. The second vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com