Method and system for improving quality of desulfuration byproduct ammonium sulfate

A by-product, ammonium sulfate technology, which is applied in the field of improving the quality of desulfurization by-product ammonium sulfate, can solve the problems of wasting absorbent ammonia or ammonia water, affecting the absorption effect, and poor production environment, so as to improve quality, avoid secondary pollution, and reduce steam volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

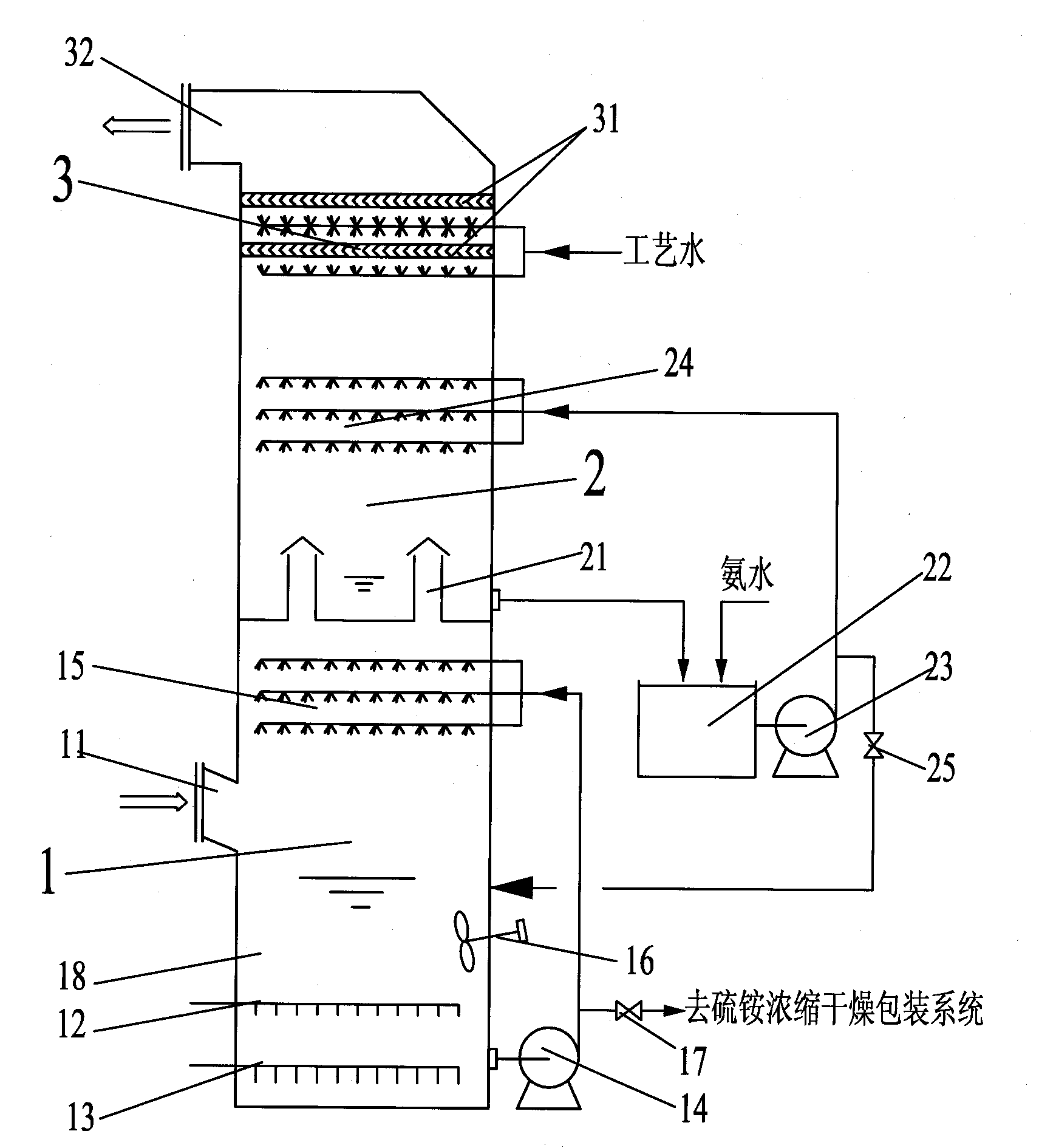

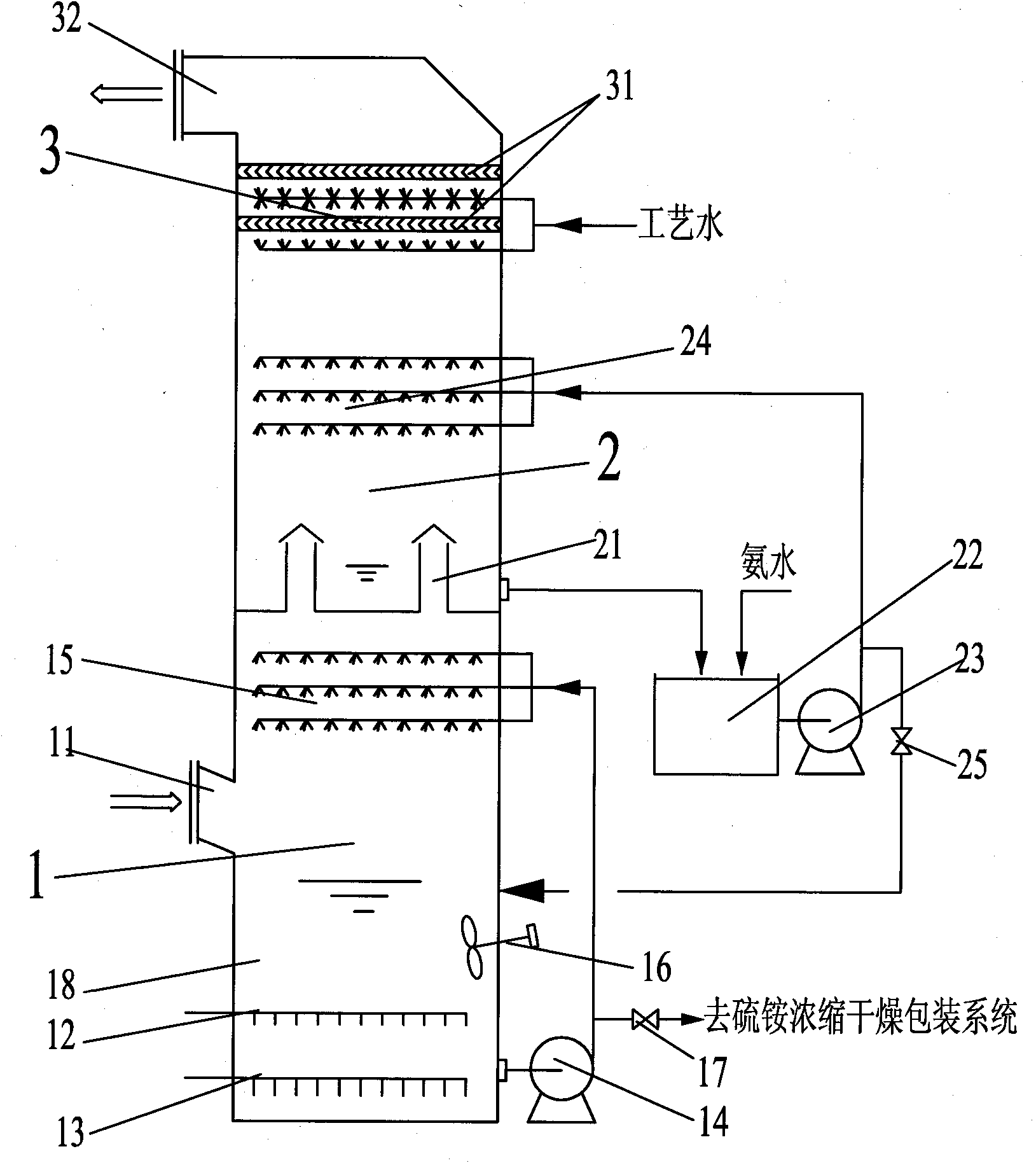

[0029] Example implementation mode: 300MW thermal power generation unit, the sulfur content of coal combustion is 2.0% to 2.6%, and the flue gas volume produced by the boiler is 1.10 to 1.18 million Nm 3 / h, SO 2 Content 6855mg / Nm 3 Around, the outlet flue gas temperature is 130 ℃ ~ 165 ℃. The flue gas directly enters the ammonium sulfate crystallization section 1 of the device system by the flue gas inlet 11, and the bottom of this section is provided with an ammonia addition device 12 and an ozone addition device 13, which is formed by SO 2 The slurry from the absorption section 2 contains a large amount of NH 4 HSO 3 and (NH 4 ) 2 SO 3 , and the mass concentration of the slurry is low, after this slurry enters the ammonium sulfate crystallization section 1, it reacts with the ammoniacal liquor ejected by the ammoniacal liquor adding device 12 rapidly, and the NH in the slurry 4 HSO 3 converted to (NH 4 ) 2 SO 3 :

[0030] NH 4 HSO 3 +NH 3 =(NH 4 ) 2 SO 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com