Method for preparing edible mushroom culture bar

A technology of edible fungi and culture medium, which is applied in the field of preparation of edible fungus culture sticks, can solve the problems of medium raw materials being inhomogeneously exposed to high-pressure steam, increasing sterilization time, and high labor intensity, so as to avoid uneven contact with high-pressure steam, Effect of shortening cooling time and saving steam volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

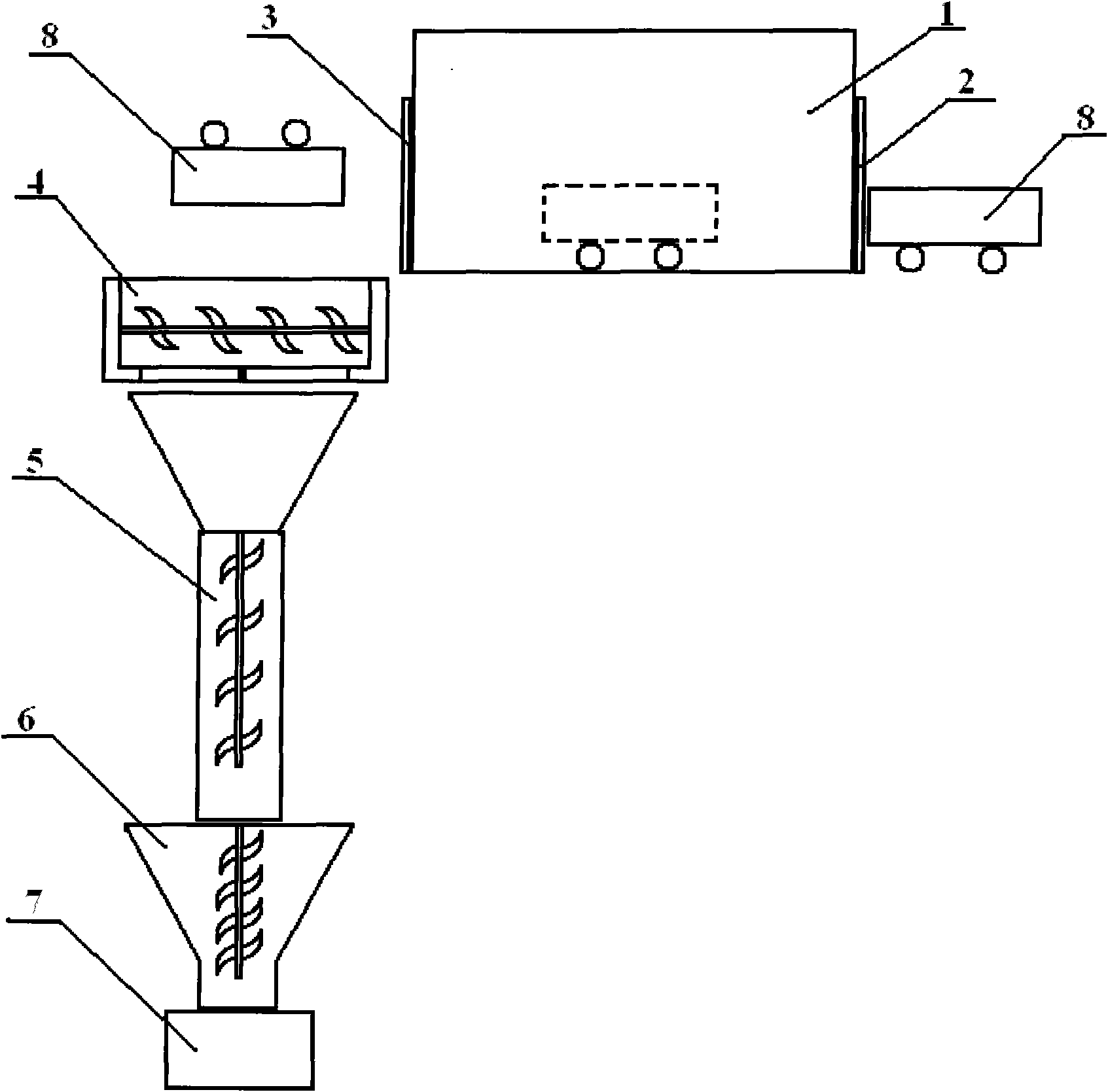

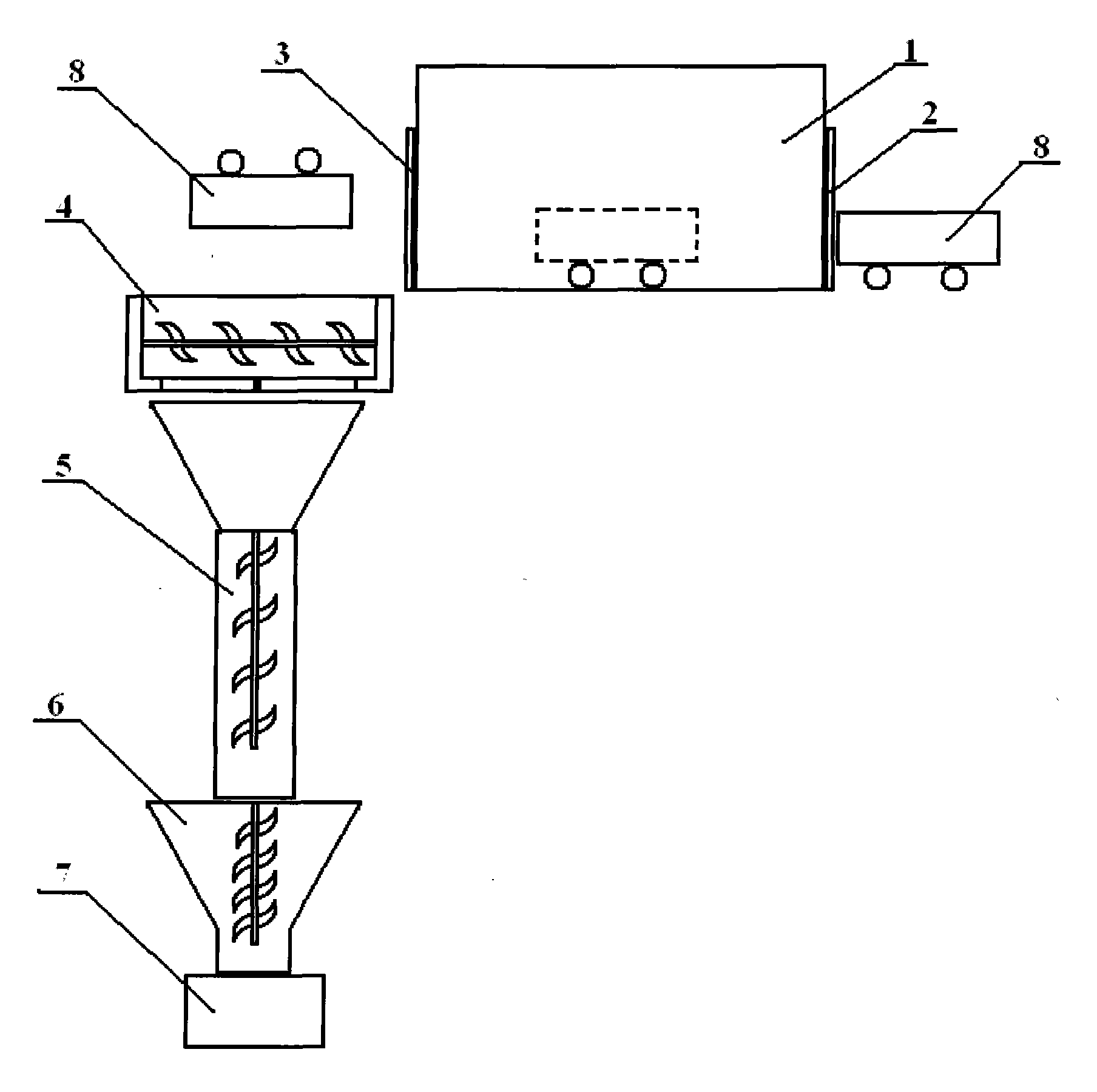

[0031] The preparation method of edible mushroom culture stick is made up of following steps:

[0032] (1) Get by weight ratio: 70% of cottonseed hulls, 6% of corncobs, 2% of calcium carbonate and 22% of wheat bran, pulverized and mixed;

[0033] (2) Load into the material transport vehicle 8, enter the sterilizer 1 from the sterilizer feed door 2;

[0034] (3) Close the sterilizer, under stirring, feed steam to raise the temperature to 120-160°C, sterilize for 30 minutes, depressurize to normal pressure, and remove the material transport vehicle from the discharge door 3 of the sterilizer set in the clean area , turned over, and unloaded into a stirring tank 4 with a jacketed bottom provided with a discharge valve;

[0035] (4) exchange heat with the cooling water partition wall and cool down to room temperature in the stirring tank provided with the discharge valve at the bottom with the jacket, open the discharge valve and discharge the material into the inoculation stirri...

Embodiment 2

[0040] The preparation method of edible mushroom culture stick is made up of following steps:

[0041] (1) Get by weight ratio: 70% of corn cob, 10% of cottonseed hull, 15% of bran, 4% of corn flour, 1% of gypsum, pulverized and mixed;

[0042] (2) Load it into the material transport vehicle and enter the sterilizer from the feed door of the sterilizer;

[0043] (3) Close the sterilizer, heat up to 120-160°C under stirring, sterilize for 40 minutes, depressurize to normal pressure, remove the material transport vehicle from the discharge door of the sterilizer set in the clean area, turn it over, and unload it. Feed to the mixing tank with a jacketed bottom and a discharge valve;

[0044] (4) exchange heat with the cooling water partition wall in the stirring tank with the bottom of the jacket provided with the discharge valve to cool down to room temperature, open the discharge valve to discharge the material into the inoculation stirring tank;

[0045] (5) Add an appropria...

Embodiment 3

[0049] The preparation method of edible mushroom culture stick is made up of following steps:

[0050] (1) Get by weight ratio: 55% of cottonseed hulls, 20% of sawdust, 18.5% of wheat bran, 5% of corn flour, 0.5% of sucrose, 1% of calcium carbonate, pulverized and mixed;

[0051] (2) Load it into the material transport vehicle and enter the sterilizer from the feed door of the sterilizer;

[0052] (3) Seal the autoclave, under stirring, feed steam to heat up to 120-160°C, sterilize for 20 minutes, depressurize to normal pressure, and remove the material transport vehicle from the discharge door of the autoclave set in the clean area, Flip over and discharge to a stirring tank with a jacketed bottom and a discharge valve;

[0053] (4) exchange heat with the cooling water partition wall in the stirring tank with the bottom of the jacket provided with the discharge valve to cool down to room temperature, open the discharge valve to discharge the material into the inoculation sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com