De-sulfur method with reproducible desulfurizer for preparing sulfuric acid as final product

A final product, desulfurizer technology, applied in the direction of separation methods, chemical instruments and methods, sulfur compounds, etc., can solve the problems of large initial investment, waste of functions, waste of energy, etc., to eliminate waste, reduce condensation, size and weight Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

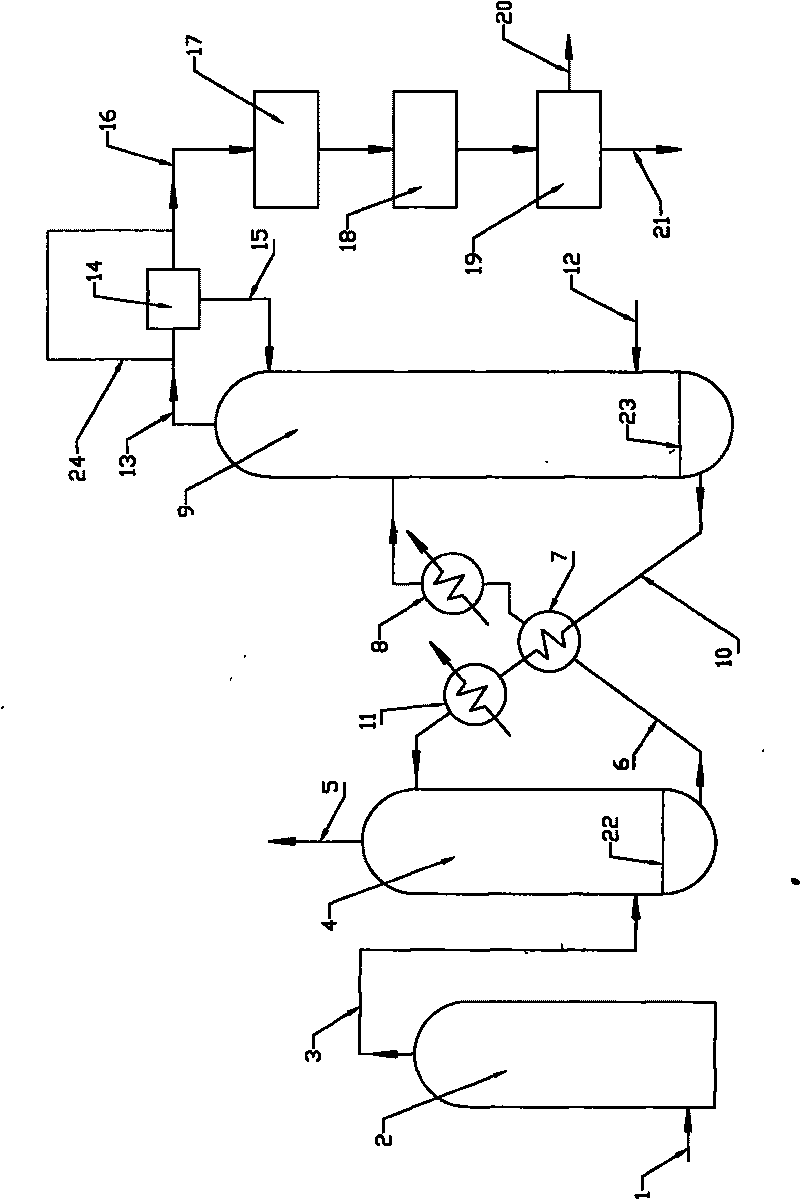

[0028] The specific implementation manner of the present invention can be described in conjunction with Embodiment 1, namely the accompanying drawings.

[0029] The main process flow of this embodiment is as follows: the flue gas to be desulfurized enters the pretreatment tower 2 from the inlet pipe 1, and in the pretreatment tower 2, the flue gas to be desulfurized is usually washed and cooled. Since the cooling water circulation and treatment system equipped for the pretreatment tower 2 belong to basic common sense, they are not shown. The pretreated flue gas to be desulfurized is sent to the lower part of the absorption tower 4 through the pipeline 3, and the SO in it is absorbed by the lean liquid that is further cooled to the technological requirement. 2 , and then discharged through the flue gas discharge pipe 5 after desulfurization. As the above-mentioned process continues, the lean liquid in the absorption tower 4 gradually becomes rich liquid, and is sent to the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com