Patents

Literature

33results about How to "Increase resource value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for obtaining transformable substrate by using fungi leftovers

InactiveCN101591688APromote digestionIncrease resource valueFermentationBiotechnologyEconomic benefits

The invention provides a method for obtaining a transformable substrate by using fungi leftovers, which comprises two steps of diluted alkaline pretreatment and cellulase saccharification. The method uses the fungi leftovers after fruiting as raw materials, changes waste materials generated by edible fungi and medicinal fungi into valuable, and not only improves the economic benefit of the productions of the edible fungi and the medicinal fungi, but also finds a new raw material for biorefinery. The method has the advantages of simple flow, simple reagent, low cost, and suitability for popularization and application.

Owner:HUAZHONG UNIV OF SCI & TECH

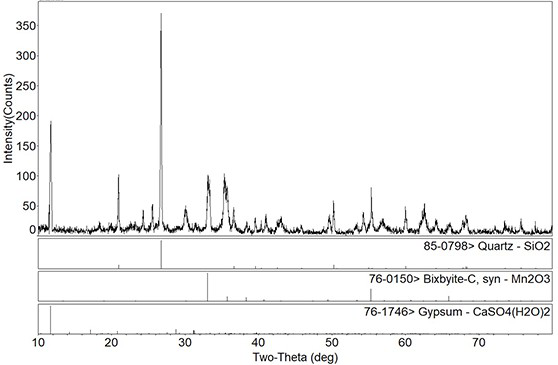

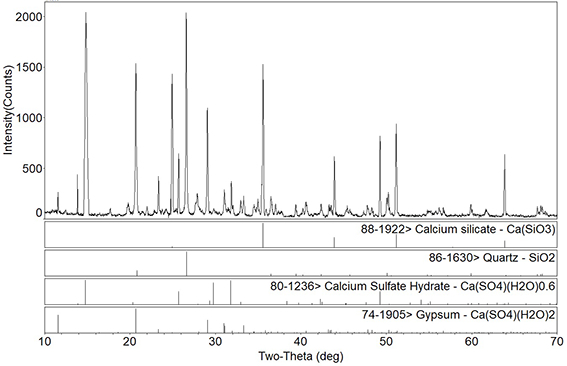

Low-grade phosphorite mineral dressing technology and method for producing by-product high-purity gypsum powder

InactiveCN102583290ARealize comprehensive utilizationSolve the shortageCalcium/strontium/barium sulfatesPhosphorus compoundsSlagMaterials science

The invention provides a low-grade phosphorite mineral dressing technology and a method for producing a by-product high-purity gypsum powder. Phosphorite is recycled and processed with hydrochloric acid to produce calcium dihydrogen phosphate and calcium hydrogen phosphate and co-produce high-purity gypsum powder. According to the method, the comprehensive utilization of accompanying elements in phosphorite resources is implemented; except for a main product calcium phosphate, three products of high silica slag, magnesium hydroxide and the high-purity gypsum powder are obtained; the high efficiency utilization of low-grade phosphorite is implemented; the resource value is promoted; the problem of phosphorus resource shortage in China is solved; a powerful support is provided for the sustainable development of phosphorus chemical industry enterprises; the economic benefits of the chemical industry enterprises are greatly improved; and great economic value and social benefits of limited mineral resources are realized.

Owner:张黔生

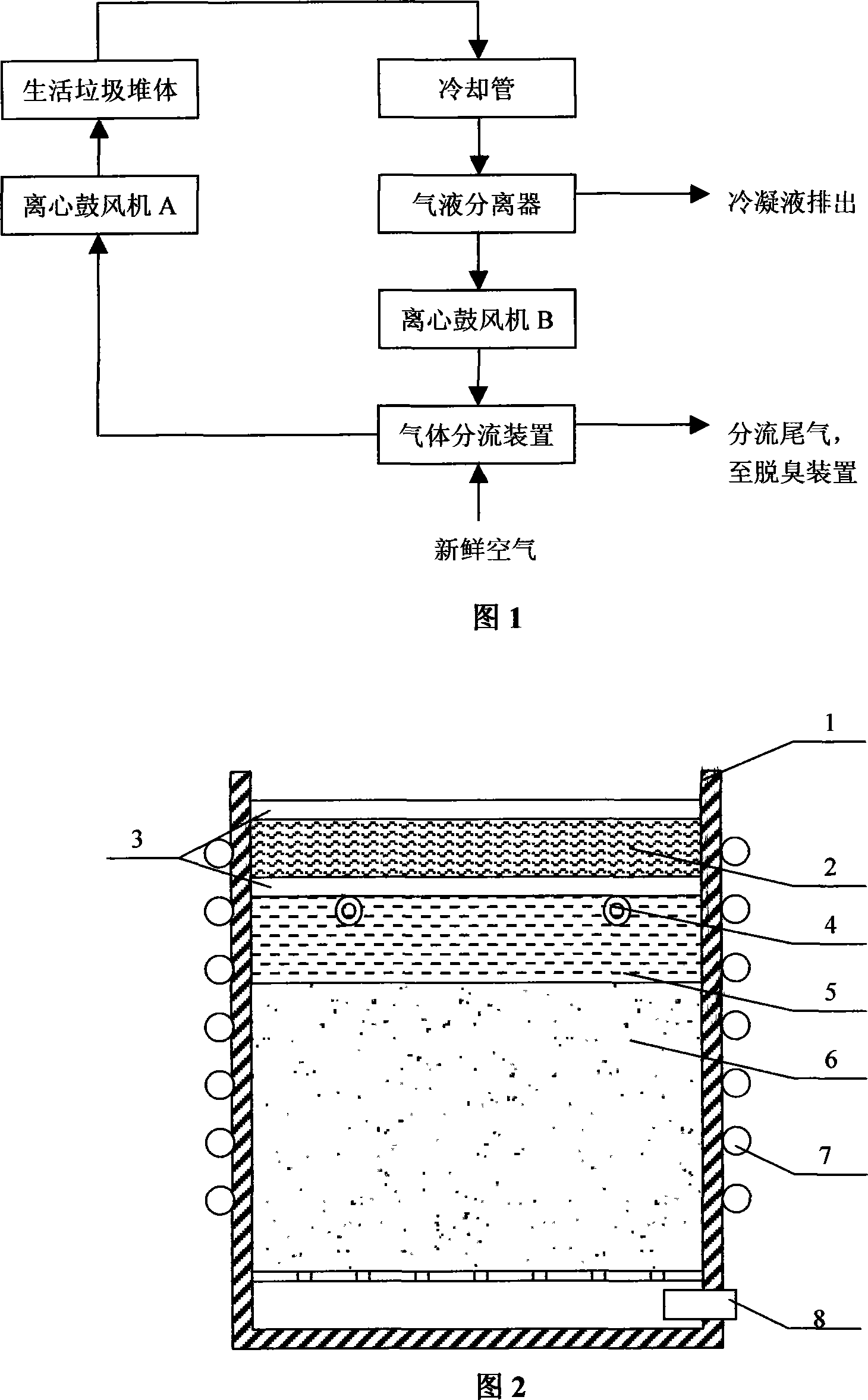

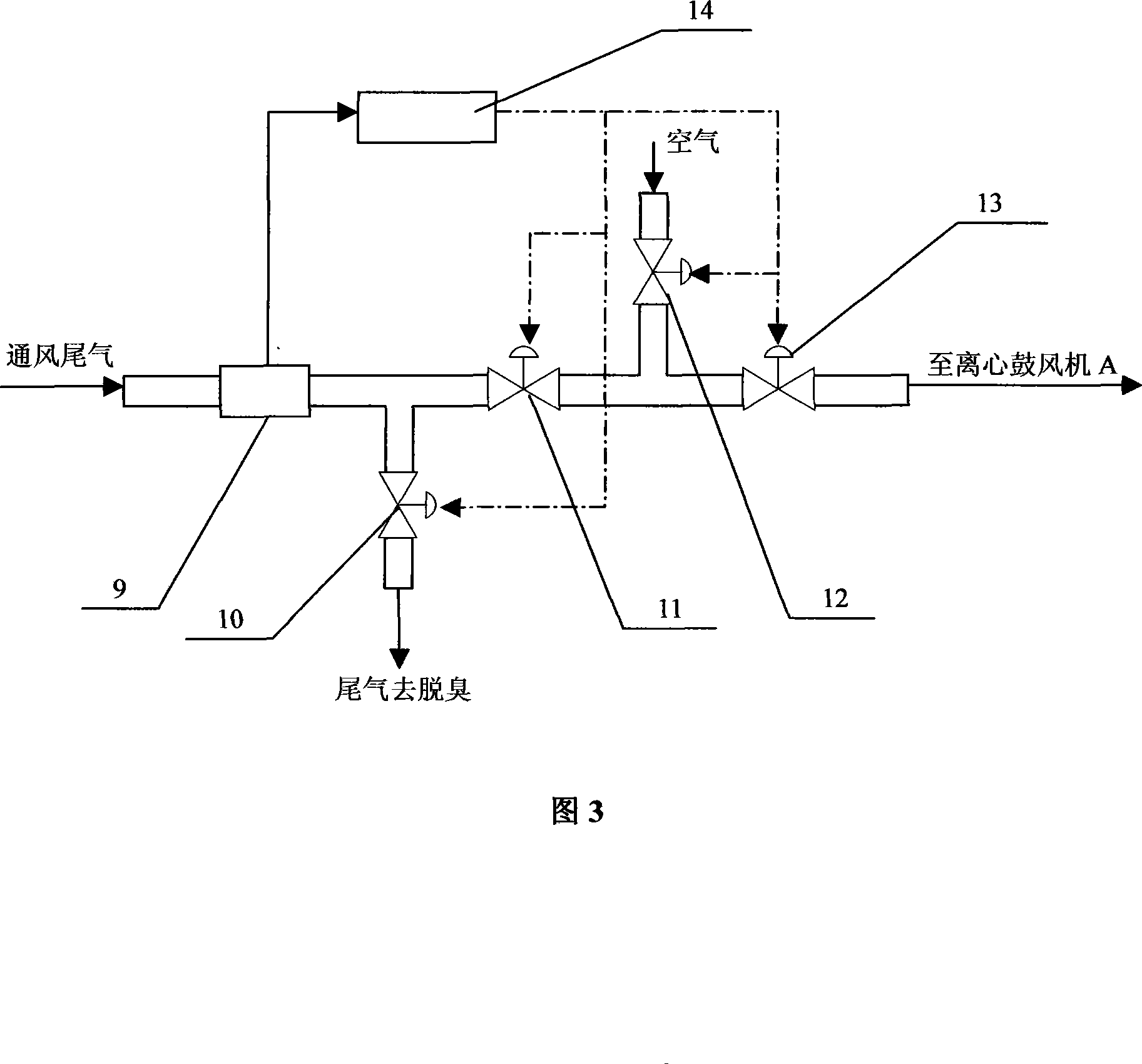

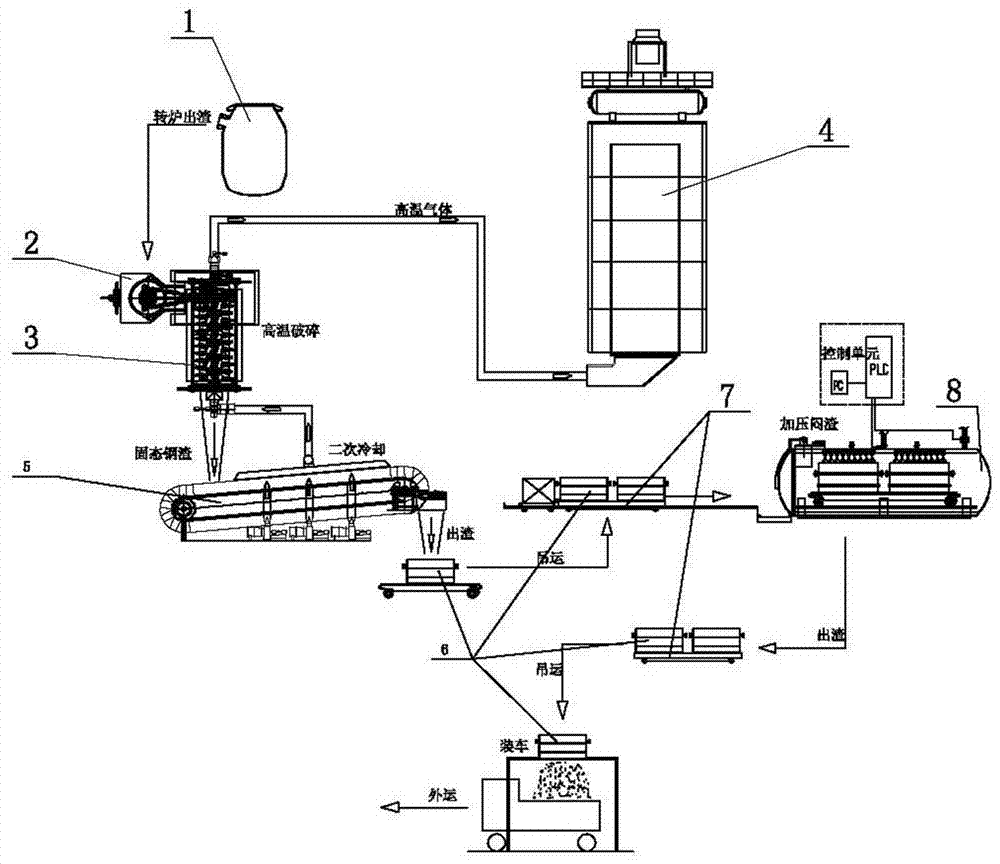

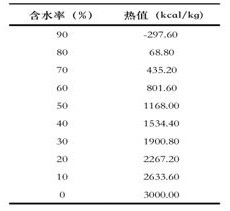

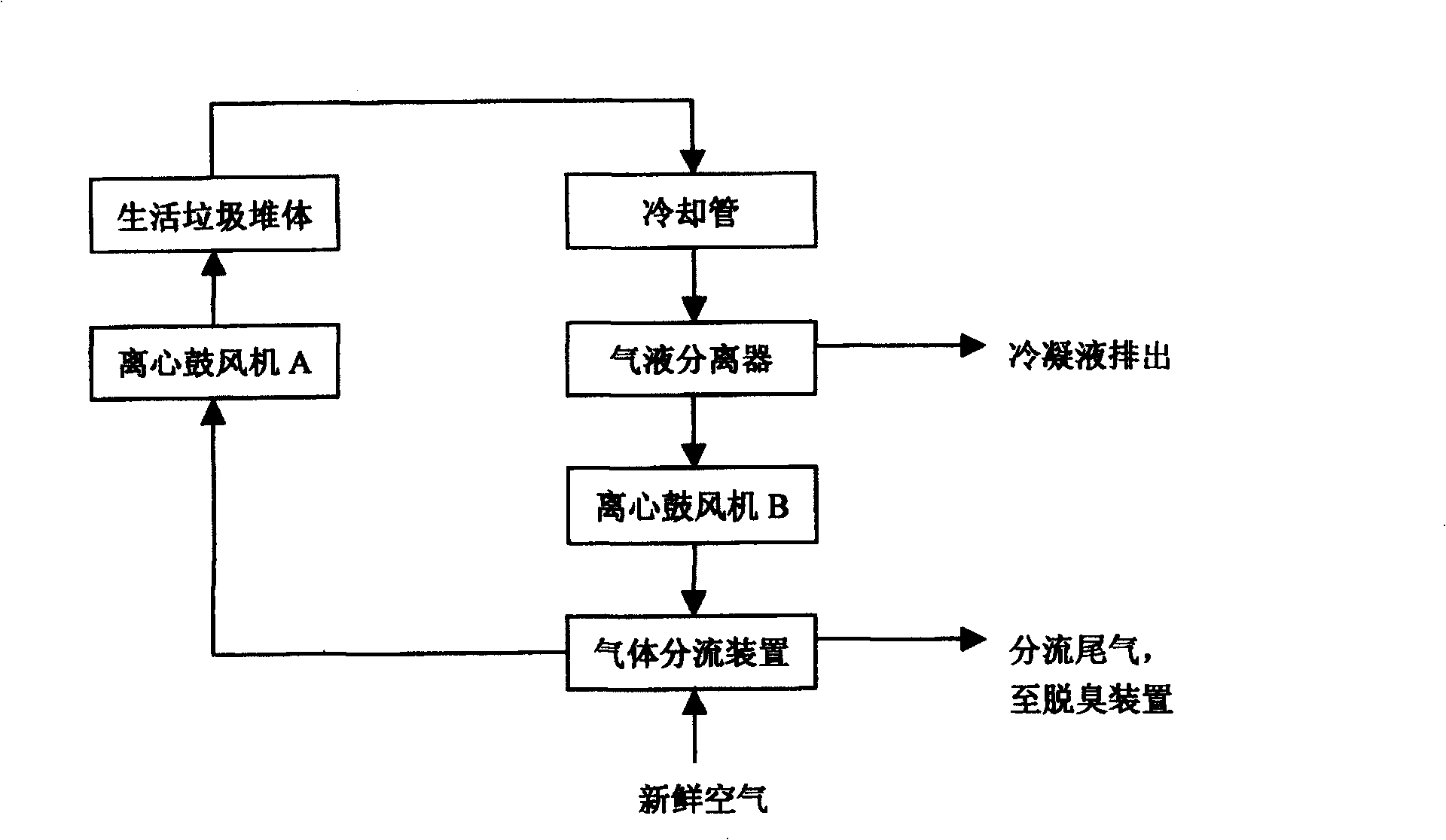

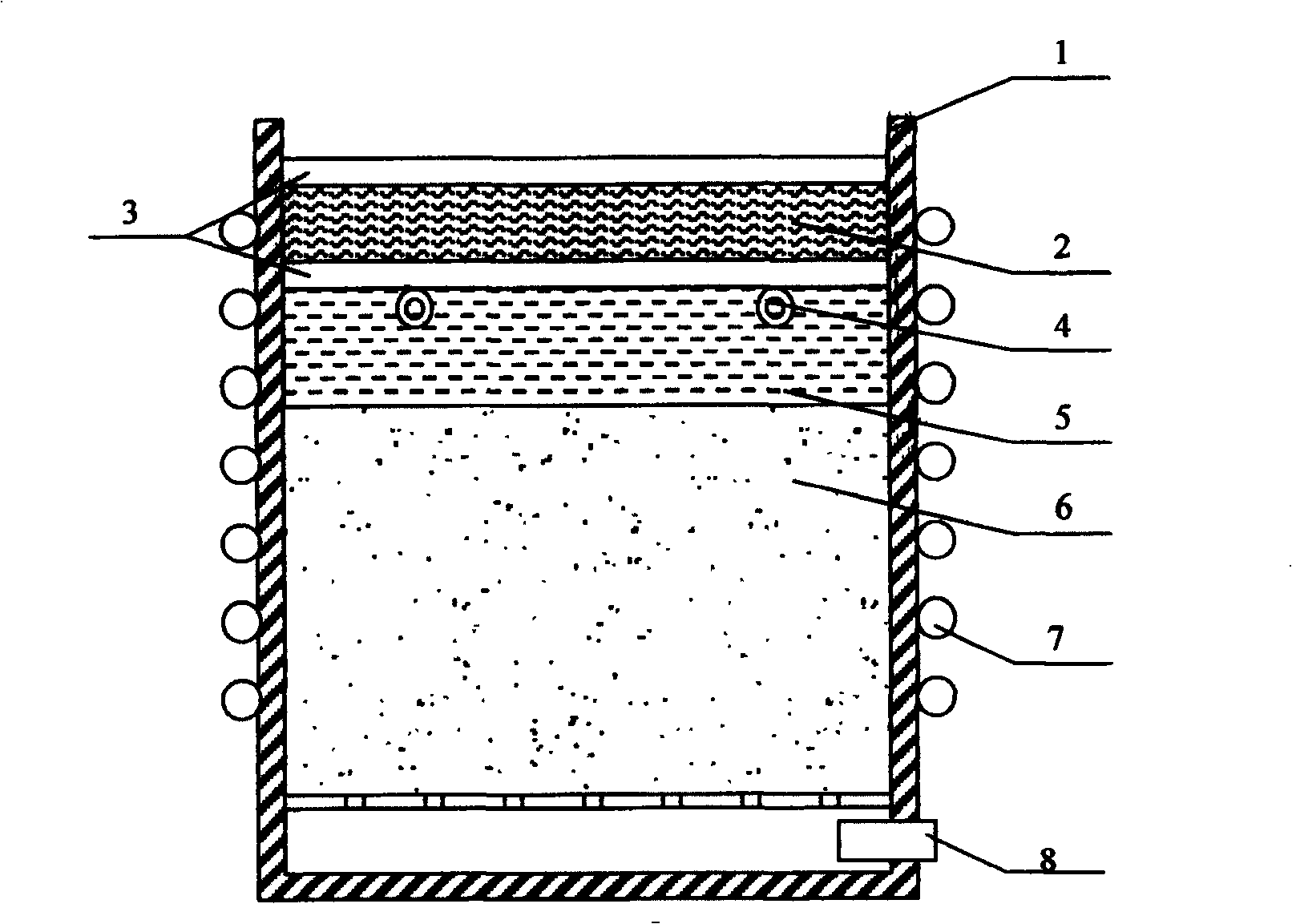

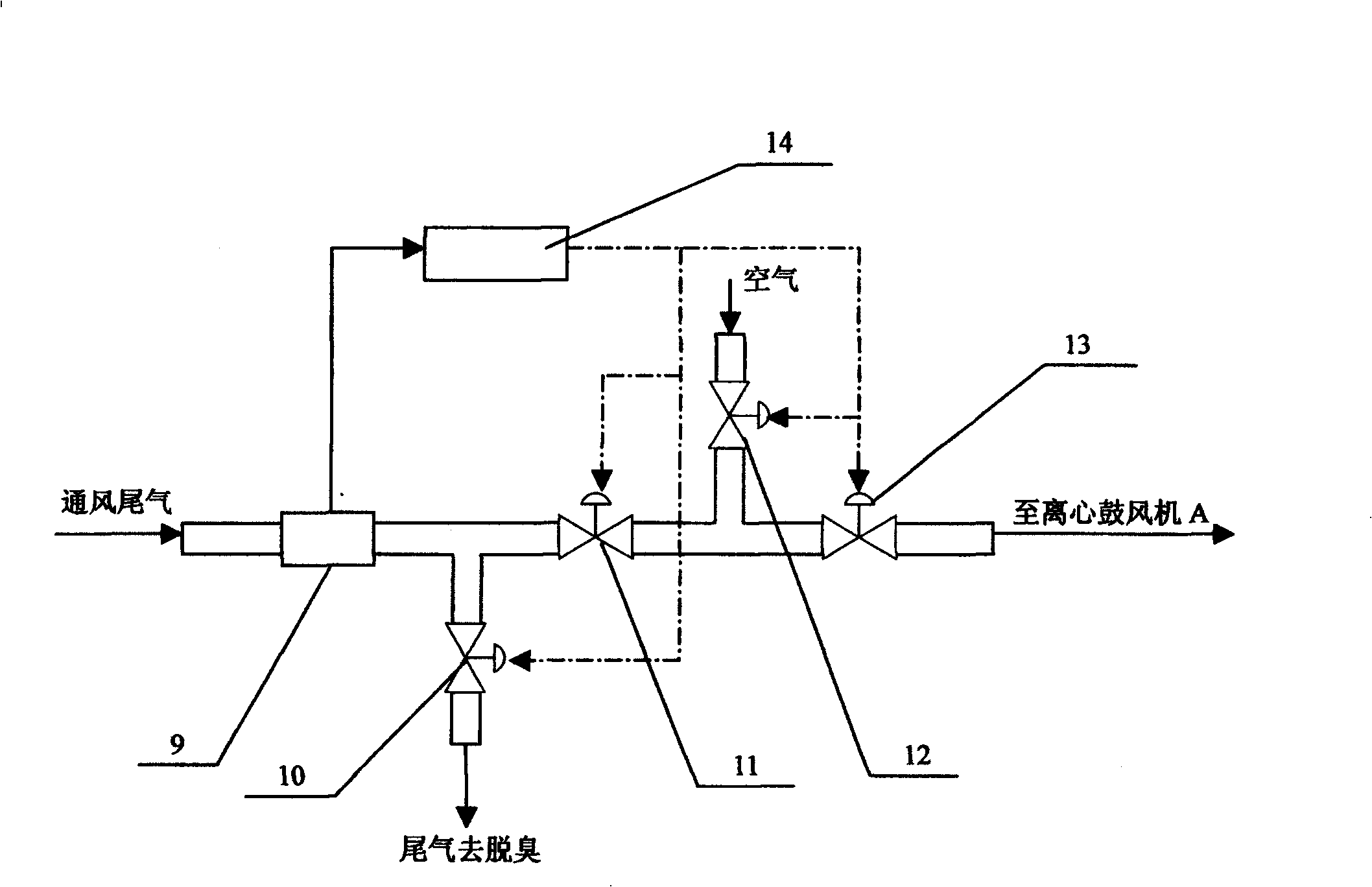

Biological drying method for life garbage

ActiveCN101025328AReduce latent heat lossReduce moisture contentDrying solid materials without heatVapor–liquid separatorLitter

A biologic method to drying life garbage, it is about a kind of technology to decrease the water of life garbage and biologic stable disposal. Firstly, after sieving out the big block from the life garbage, to stack it into groove-shape compost reactor, then to cover tying straw pad and compound heat insulating coiled material, to bonds the opening rubber tail gas gathering tube with the cooling tube under the coiled material. The cooling tube is connected with gas-liquid separator, centrifugal blast blower B, gas separation unit and centrifugal blast blower A sequentially, and the centrifugal A is connected with the bottom of the reactor. Secondly, to vent the air fitfully and circularly with firm discharge, to turn one time on the second day and the fourth day respectively, to complete drying in six days, offgas enters gas separation unit after liquor condensate is eliminated by the cooling tube and gas-liquid separator, after discharging part of offgas into off-odor unit, to supply equivalent clean air, then to put the offgas into the centrifugal A for garbage venting. The quantity of offgas off odor and running cost of this invention is low, the water-content coefficient of the garbage is smaller than 40% after disposal, and it can be used for drying the life garbage with water-content coefficient 60%.

Owner:TONGJI UNIV

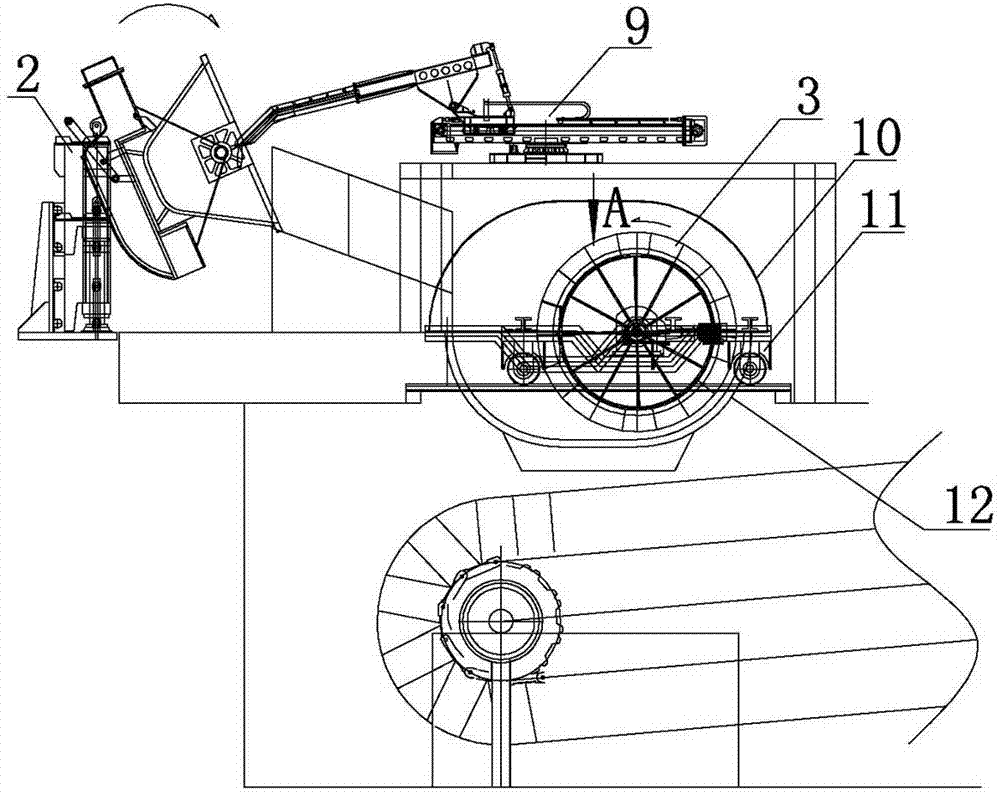

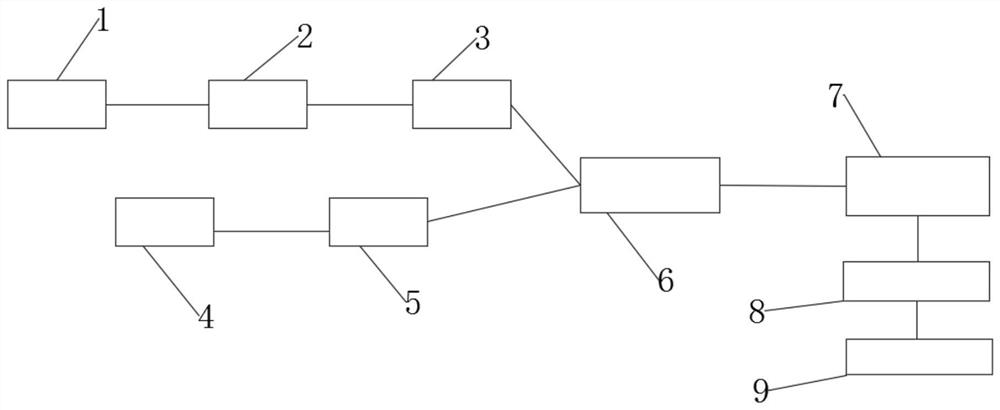

Steel slag waste heat recovery and pressurized slag disintegrating system and technology

PendingCN107164588AImprove stabilityIncrease resource valueExhaust gas handlingIncreasing energy efficiencySlagWaste heat

The invention discloses a steel slag waste heat recovery and pressurized slag disintegrating system and technology. The system comprises a slag ladle tilting mechanism, a roller, a waste heat boiler, a straight-line cooler, a slag disintegrating tank, a slag ladle trolley, slag disintegrating pressurization kettles and a slag removal machine. The slag ladle tilting mechanism can tilt a slag ladle containing steel slag. The surface of the roller is provided with spirally-arranged roller teeth. The lower portion of the roller is provided with a steel slag groove. The steel slag groove is provided with a sealing cover. The steel slag in the tilted slag ladle can be conveyed into the steel slag groove through the slag removal machine, and a discharge outlet of the steel slag ladle is located above the straight-line cooler. Air is adopted as a heat exchange medium, a first fan blows air into a high-temperature material layer of the straight-line cooler, indoor-temperature air penetrates through the high-temperature steel slag from bottom to top, air is heated, and first-step heat exchange is completed. Air subjected to heat exchange through the straight-line cooler enters the roller, gas penetrates through the stirred steel slag to be further heated, and secondary heat exchange is completed. High-temperature gas is sucked to the waste heat boiler through a second fan, and therefore waste heat recovery is achieved.

Owner:JIGANG INT ENG & TECH CO LTD

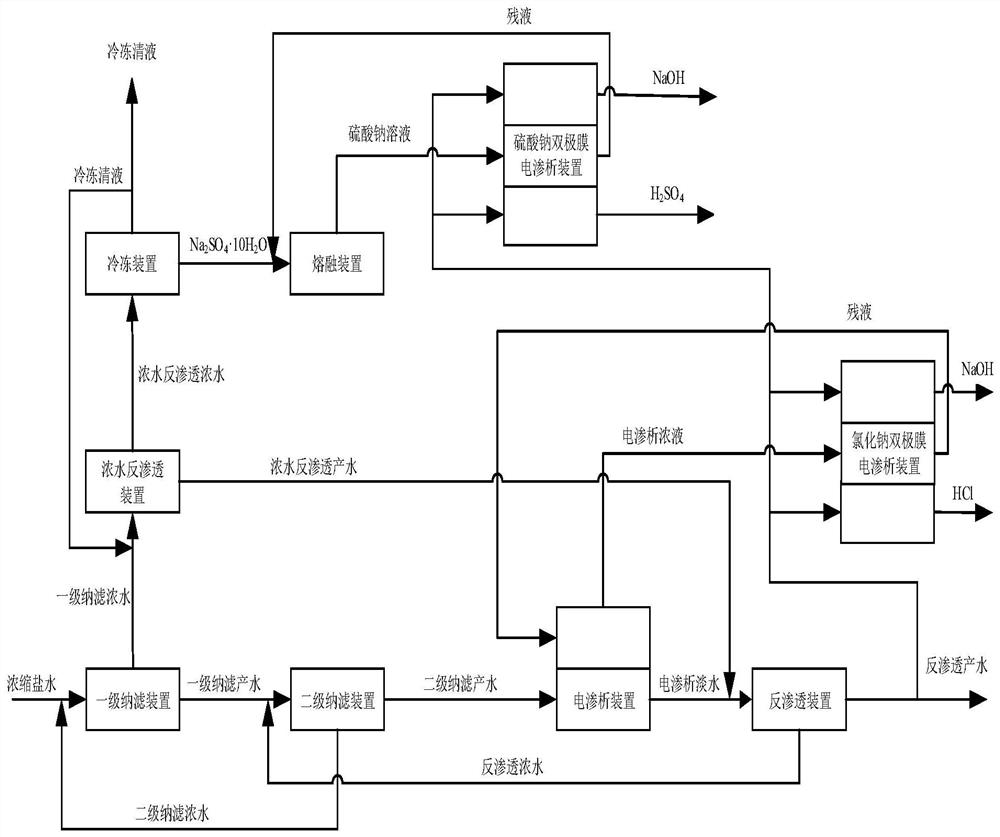

Concentrated brine retreatment system and process

InactiveCN111892221ALow running costReduce hazardous waste disposal feesMultistage water/sewage treatmentWater/sewage treatment by freezingReverse osmosisSodium sulfate

The invention relates to a sewage treatment device and method, in particular to a concentrated brine retreatment system and process, and aims to solve the problems that by-product miscellaneous salt produced in the traditional wastewater treatment process has no reutilization value, crystalline miscellaneous salt has extremely high solubility and poor stability and curability, the risk of secondary pollution exists, and the treatment cost of the crystalline miscellaneous salt is high. The system comprises a primary nanofiltration device, a secondary nanofiltration device, an electrodialysis device, a reverse osmosis device, a concentrated water reverse osmosis device, a freezing device additionally provided with a melting device, a sodium chloride bipolar membrane electrodialysis device and a sodium sulfate bipolar membrane electrodialysis device. Alkali, hydrochloric acid and reuse water are prepared by adopting a two-stage nanofiltration, electrodialysis, bipolar membrane electrodialysis and reverse osmosis coupling process; alkali and sulfuric acid are prepared by adopting a primary nanofiltration, concentrated water reverse osmosis, freezing and bipolar membrane electrodialysiscoupling process.

Owner:SHAANXI AEROSPACE ELECTROMECHANICAL ENVIRONMENTAL ENG DESIGNING INST CO LTD

Material and preparation method for granular filler paper pulp molded product

InactiveCN110331624AImprove physical strengthReduce dosageDefoamers additionWater-repelling agents additionFiberPrill

The present invention relates to the field of paper pulp molded packaging products, and especially relates to a method for preparing a novel pulp molded product from a granular filler. The method comprises the following steps: uniform mixing of proper amounts of plant fibers, biomass particles, a sizing agent, a reinforcing agent, a dispersant, a retention and drainage aid, a plasticizer, a defoaming agent and water, mold adsorption, vacuum suction filtration, compression molding, drying or natural drying, hot pressing shaping, and cutting for producing the molded product having a moisture content of 8-12%. The pulp molded product prepared in the invention can reduce the dosage of the plant fibers by up to 60%, has a higher physical strength than conventional pulp molded products, can reduce the use of forest resources, is economical and environmentally friendly, and can be reused or naturally degraded and returns to soil after being used.

Owner:JIANGNAN UNIV

Kitchen waste desalting, fermenting and composting technology

InactiveCN113213983AIncrease resource valueReduce pollutionClimate change adaptationOrganic fertilisersDesalinationWater resources

The invention relates to a kitchen waste desalting, fermenting and composting technology. Organic waste is continuously added, the extruding and crushing effects of double-screw conveying are matched with water washing, after the kitchen waste is desalted, solid substances are fermented, and the efficient, stable and continuous composting process is ensured, so that the efficient reduction, harmlessness and recycling of the kitchen waste are realized, and the influence of salt on resource products is effectively removed. The technology has the advantages of simplicity and convenience in operation, simple process, high automation degree, small occupied area and the like, and circulating water is used for desalting treatment, so that the utilization efficiency of water resources is improved, and meanwhile, the resource value of products is greatly improved; and the application of the technology can effectively reduce the pollution of the kitchen waste to the environment, and also realizes the resource utilization of the waste.

Owner:NANKAI UNIV +1

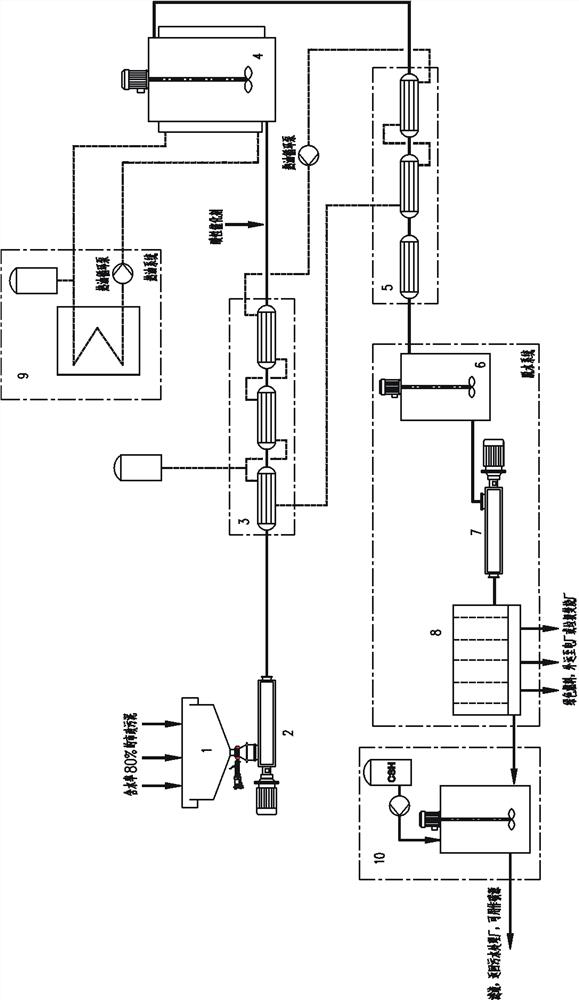

Urban sludge low-temperature hydrothermal carbonization coal production recycling system

PendingCN111875210AKill completelyHigh fuel value and environmentally friendlySludge treatment by pyrolysisChemical industryAutomatic controlProcess engineering

The invention discloses an urban sludge low-temperature hydrothermal carbonization coal production recycling system which greatly improves the combustion value of biochar and enhances the sludge incineration efficiency through a vacuum drying and squeezing system. A phosphorus recovery device is added to recover phosphorus in sewage and develop the additional value of phosphorus. The integrated system comprises a feeding system, a carbonization system, a heat exchange system, a discharging system, a dehydration system, a dosing system, a phosphorus recovery system, an automatic control systemand the like, and is characterized in that the excess sludge is converted into green fuel (charcoal), and phosphorus is recovered, so that the excess sludge is harmless, stable, reduced, recycled, economical and efficient. According to the technology, urban sludge low-temperature hydrothermal carbonization coal production recycling is provided, and sludge is pyrolyzed in an anaerobic environment to produce biochar. The biochar formed after hydrothermal carbonization and vacuum drying and squeezing is high in combustion value, environmentally friendly, high in resource utilization rate and remarkable in energy conservation.

Owner:四川欧美华环境工程有限公司

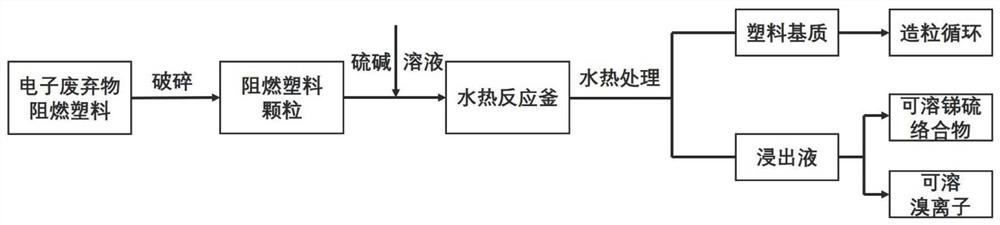

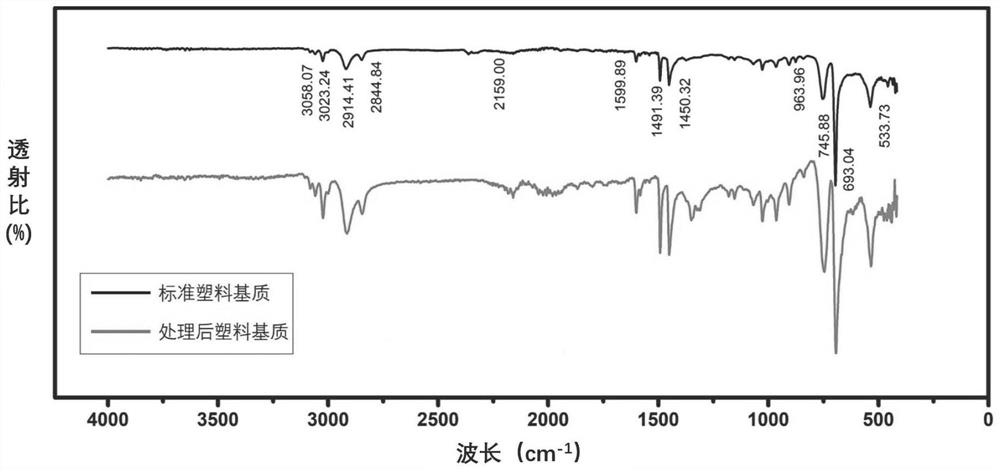

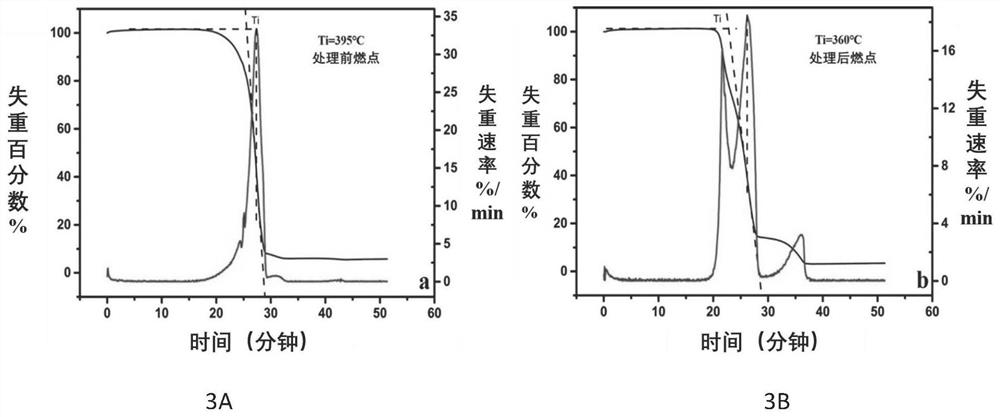

Method for synchronously removing antimony and bromine from electronic waste flame-retardant plastic and recovering plastic matrix

The invention discloses a method for synchronously removing antimony and bromine from electronic waste flame-retardant plastic and recovering a plastic matrix. The method comprises the following steps: crushing the electronic waste flame-retardant plastic, creating a sulfur-alkali reaction atmosphere in a hydrothermal environment, carrying out hydrothermal sulfur-alkali reaction on the crushed flame-retardant plastic in the sulfur-alkali reaction atmosphere, synchronously removing antimony and bromine flame retardants, and recovering to obtain the plastic matrix with small structural performance change. Antimony and bromine flame retardants contained in the flame-retardant plastic are efficiently and synchronously removed, and the plastic matrix capable of being used for mechanical re-granulation is recycled. The method has outstanding advantages in the aspects of environmental pollution reduction and energy resource utilization, and has the characteristics of good removal effect, low operation cost, high resource value, no pollution to the environment and the like.

Owner:SHANGHAI JIAO TONG UNIV

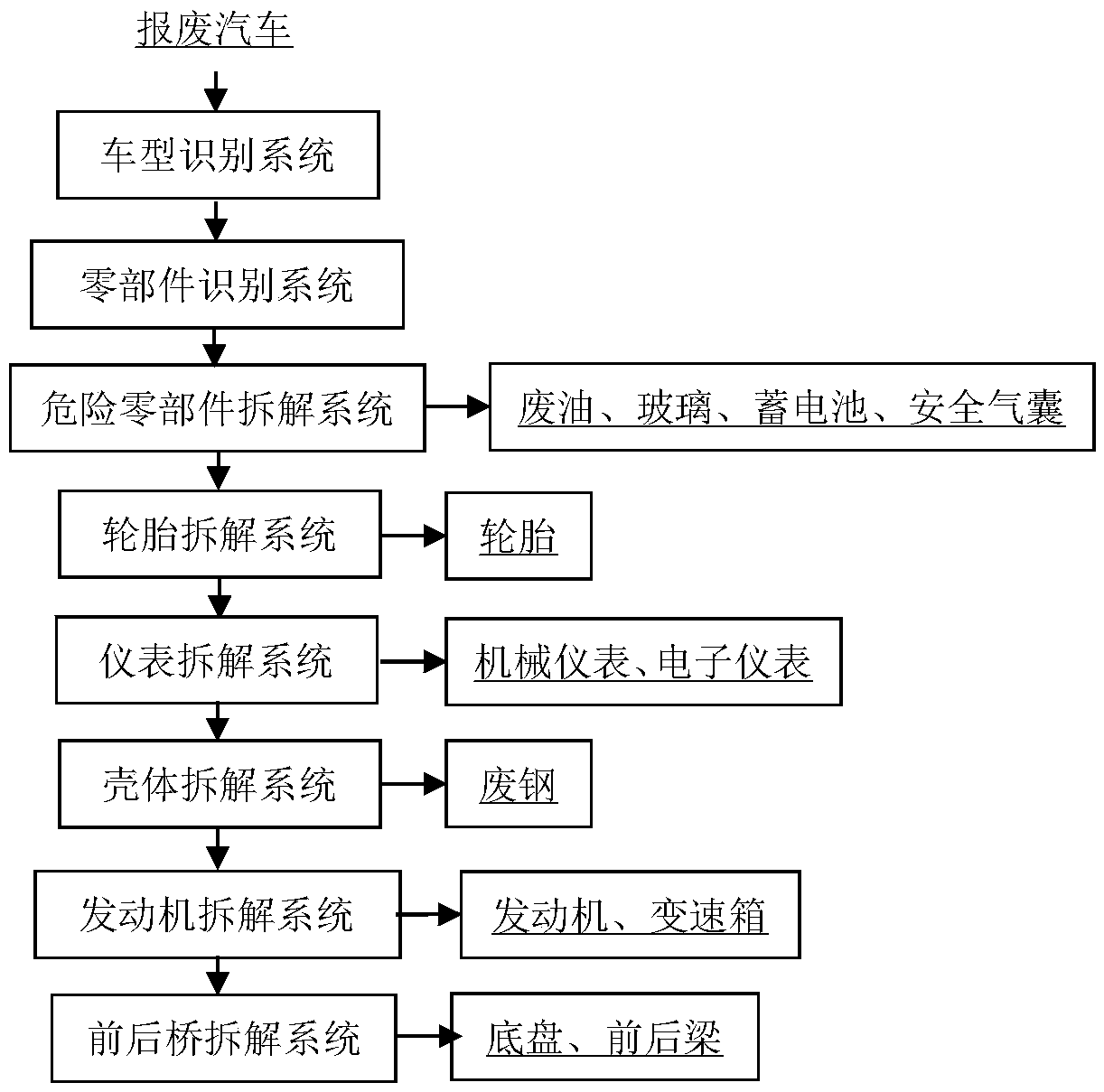

Reverse flexible disassembling line for scraped vehicles

ActiveCN109178150ARealize intelligent dismantlingImprove dismantling efficiencyVehicle dissasembly recoverySolid waste disposalTransfer systemIdentification system

The invention discloses a reverse flexible disassembling line for scraped vehicles, and relates to the field of scraped automobiles recovery. The reverse flexible disassembling line for scraped vehicles comprises a vehicle type identification system, a component identification system, a hazardous component disassembling system, a tire disassembling system, an instrument disassembling system, a shell disassembling system, an engine disassembling system, a front and rear axle disassembling system, a transfer system and the like. The disassembling method comprises the following steps: firstly, adatabase of vehicle types and components is established, and the vehicle types are judged by the vehicle type identification system; then the dangerous parts, tires, instruments, housings, engines, front and rear axles are identified and disassembled by the component identification system in turn, and the disassembled components are sorted into warehouses by the transfer system. The reverse flexible disassembling line for scraped vehicles adopts flexible disassembly to realize efficient and intelligent disassembling of scraped vehicles.

Owner:UNIV OF SCI & TECH BEIJING

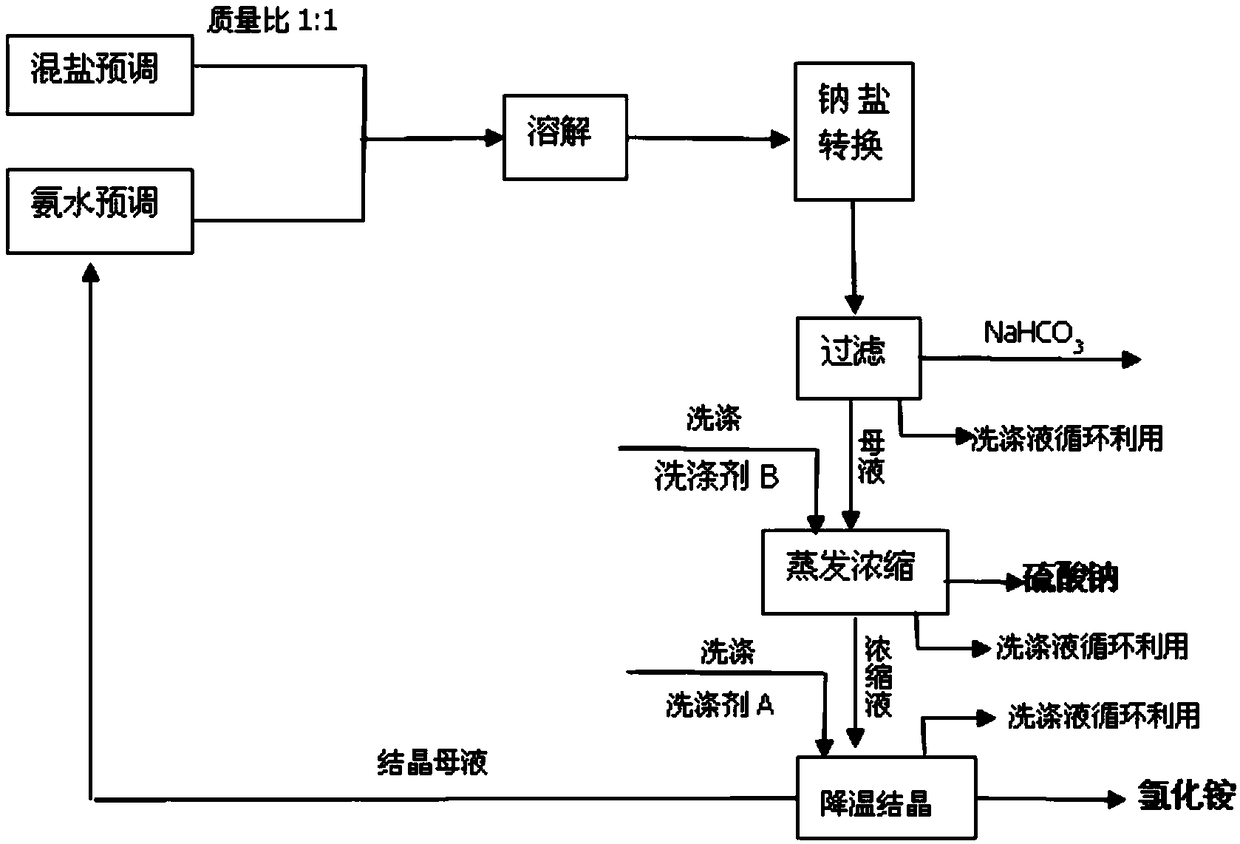

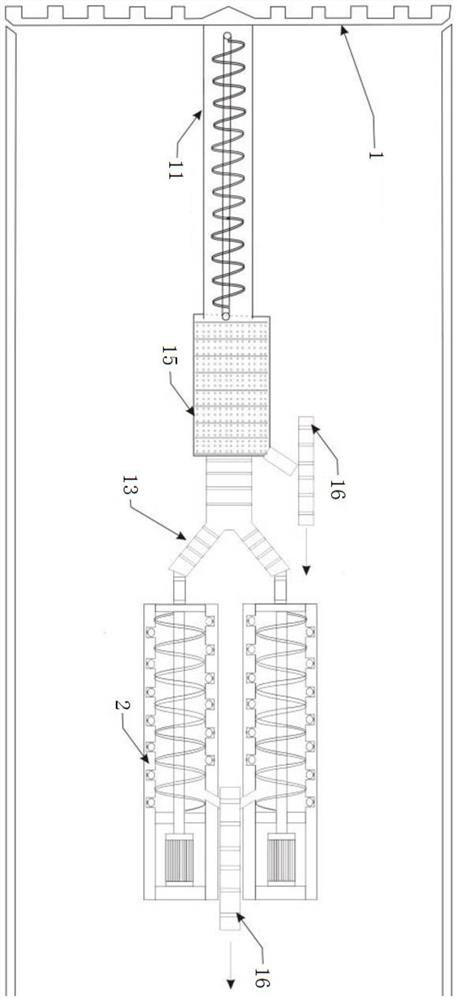

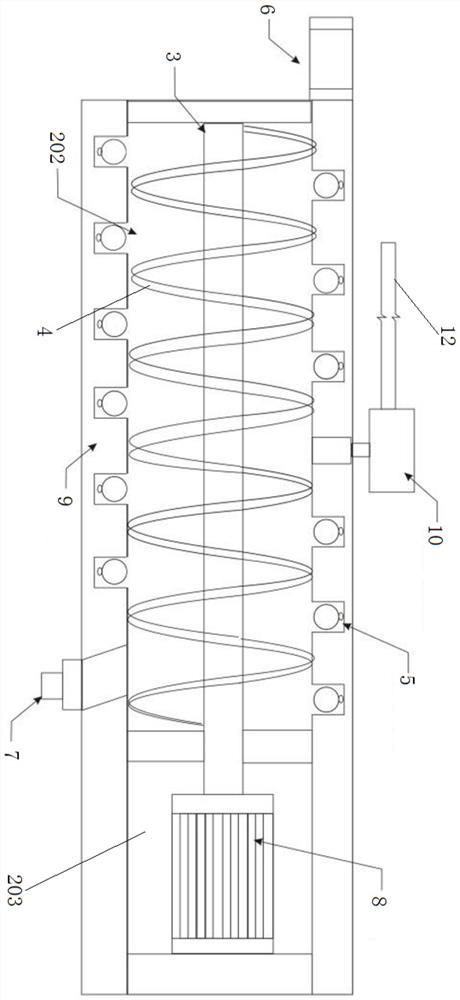

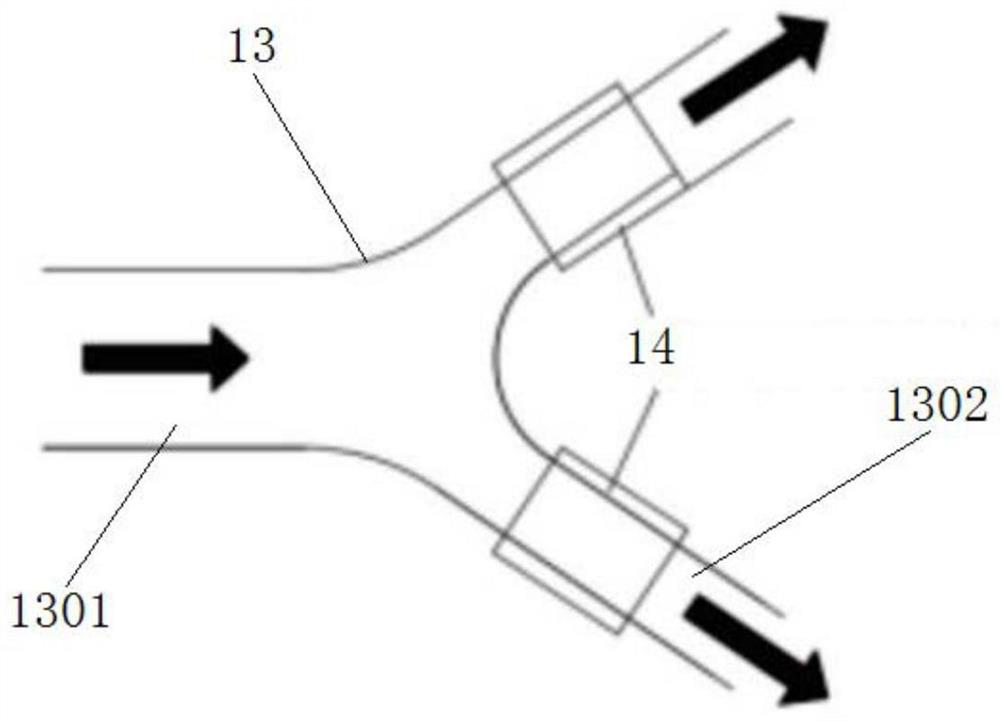

Separating and using method for mixed sodium salt

InactiveCN109368667ASeparation is easier and more thoroughIncrease resource valueProductsReagentsChemistryCarbon dioxide

The invention provides a separating and using method for mixed sodium salt. The method comprises the following steps: A) adding the mixed sodium salt to ammonia water, to obtain ammoniacal brine, wherein a mass ratio of sodium sulfate and sodium chloride in the mixed sodium salt is 1:(0.5-2), and concentration of the ammonia water is 8-12%; B) feeding carbon dioxide to the ammoniacal brine, performing a gas liquid reaction, to obtain a mixed system, wherein a feeding quantity of the carbon dioxide is 10-30 L / h; C) performing evaporation and concentration on the mixed system, separating out andcrystallizing, to obtain saline mixture; and D) filtering the saline mixture, washing filter residue by using sodium sulfate saturated solution, to obtain a sodium sulfate product, cooling and crystallizing filtrate, washing a separated crystal by using ammonium chloride saturated solution, to obtain an ammonium chloride product. The method is capable of, on the basis of separating and recoveringthe sodium sulfate, converting the sodium chloride into the ammonium chloride with the wider application range, and providing a new technology for separation of the sodium sulfate and the sodium chloride.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

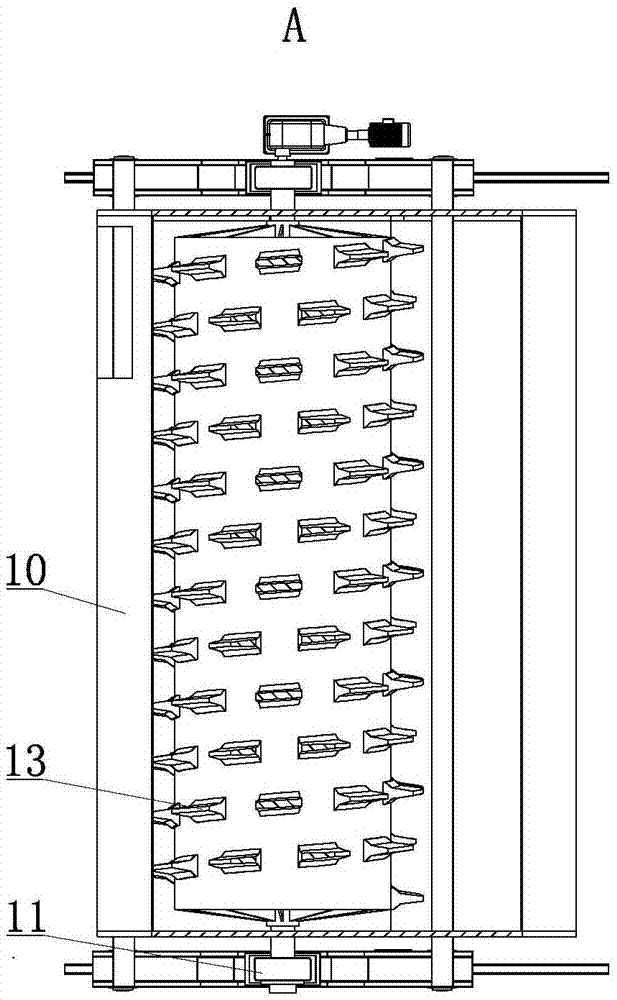

Shield tunneling machine with muck drying function and muck drying method thereof

PendingCN114215536ARealize solid-liquid separationEasy to handleSievingScreeningEnvironmental engineeringShield tunneling

The invention provides a shield tunneling machine with a muck drying function and a muck drying method of the shield tunneling machine. The shield tunneling machine comprises a plurality of dryers arranged in a shield tunneling cutter head. Each dryer comprises a shell of a cylindrical structure, and a stirring dehydration tank and a sealing area which are independent of each other are arranged in the shell. A rotating shaft is arranged in the stirring and dewatering tank, stirring blades of a spiral structure are arranged on the rotating shaft, and a plurality of circles of drying lamp tubes are annularly arranged on the inner wall of the stirring and dewatering tank; a slag inlet and a slag outlet which are communicated with the interior of the shell are respectively formed in two ends of the shell; according to the scheme, the dryer achieves drying operation in a shield machine room, the synchronous treatment capacity and efficiency of shield waste muck are improved, solid-liquid separation of gravel, soil and water in the shield muck can be achieved, the dryer is used for recycling in tunneling operation, and therefore the shield waste muck can be recycled. The resource value of the shield waste muck is greatly improved, and the total risk and cost in the shield waste muck treatment process are reduced.

Owner:成理科技(成都)股份有限公司

Paper product filler pretreatment device and process

PendingCN109331756ASave resourcesLow costPressurized chemical processWaste product additionFiberChemical reaction

The invention discloses a paper product filler pretreatment device and process. The treatment device comprises a screw rod pump, a homogenizer, a material conveying pump, a metering tank, a microwavereactor, a main reactor, an energy transduction system, a decompressor, a dehydrator, a backflow water tank and a backflow water pump. The pretreatment process comprises the following steps: feeding araw filler into the homogenizer through a pipeline, adding a part of a high-temperature circulation liquid into the homogenizer, carrying out homogenization and heating, and conveying the mixed raw filler into the microwave reactor through the material conveying pump; feeding a middle filler pretreated by using the microwave reactor into the main reactor through a pipeline; carrying out secondarycirculation liquid mixing heating and auxiliary heating on the middle filler in the main reactor, and carrying out a thermal chemical reaction; in the energy transduction system, and effectively exchanging heat of a filler solution treated after the thermal chemical reaction in the main reactor to circulated water. By adopting a paper product prepared from the filler, a great amount of plant fiber resources can be saved. Meanwhile, the plant fiber resources are saved, and the raw material cost of the paper product is also reduced.

Owner:JIANGNAN UNIV

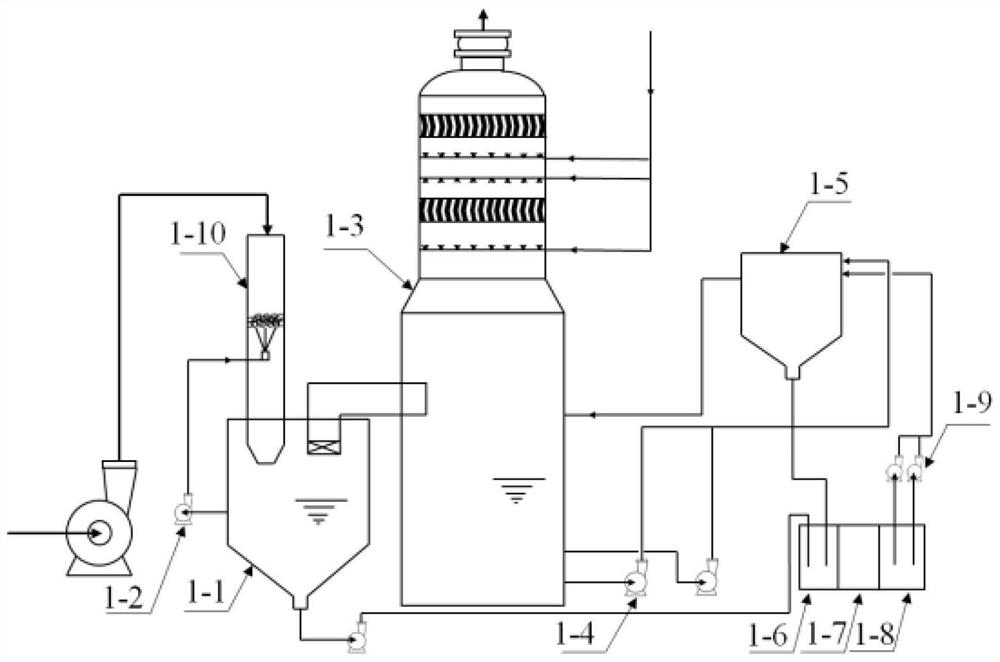

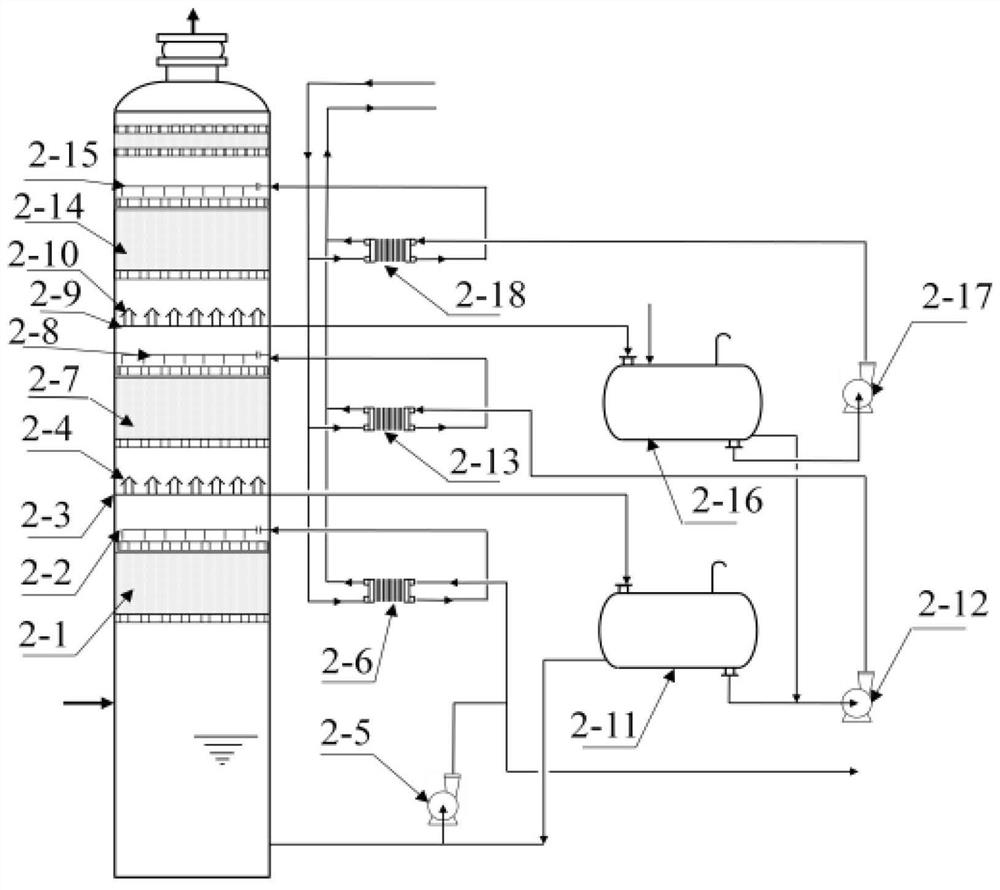

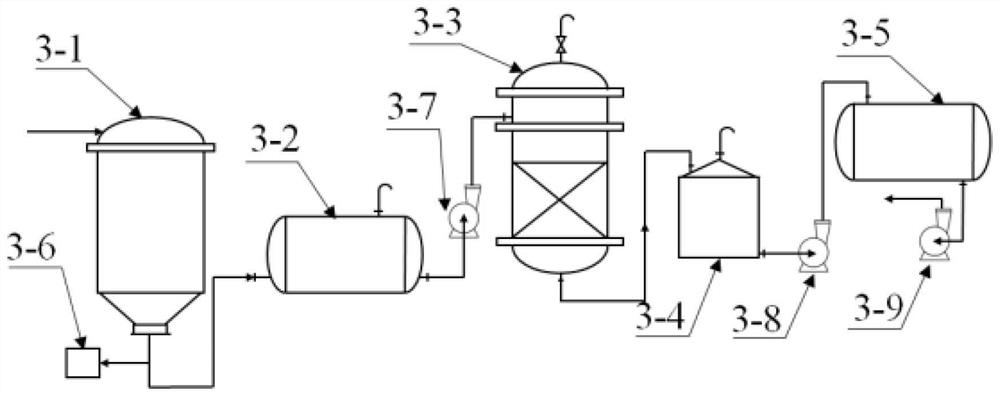

Intelligent regulation and control system and method for preparing high-added-value products from SO2 absorption by-products

ActiveCN112892188AImprove desulfurization efficiencyIncrease resource valueGas treatmentUsing liquid separation agentProcess engineeringAmmonium bisulfite

The invention relates to an intelligent regulation and control system and a method for preparing high-added-value products from SO2 absorption by-products, and the system comprises a flue gas purification cooling subsystem, a flue gas desulfurization subsystem, an ammonium bisulfite refining subsystem, a hydroxylamine sulfate preparation subsystem and a high-added-value product preparation subsystem which are sequentially arranged, the flue gas purification cooling subsystem and the flue gas desulfurization subsystem are arranged in a flue between an SCR denitration system and a power plant chimney, and the flue gas desulfurization subsystem, the hydroxylamine sulfate preparation subsystem and the high value-added product preparation subsystem are respectively connected with an intelligent regulation and control subsystem. According to the invention, multi-means such as flue gas purification and cooling, segmented efficient desulfurization, ammonium bisulfite refining, high-added-value product preparation, intelligent multi-factor regulation and control and the like are adopted, so that full-process multi-means matching optimization control such as flue gas pre-purification and washing-ammonium bisulfite oxidation inhibition-oxime intermediate refining and the like is realized; and preparation of high-added-value products such as finished oxime is realized at low cost at the same time of realizing high efficiency SO2 removing.

Owner:ZHEJIANG UNIV

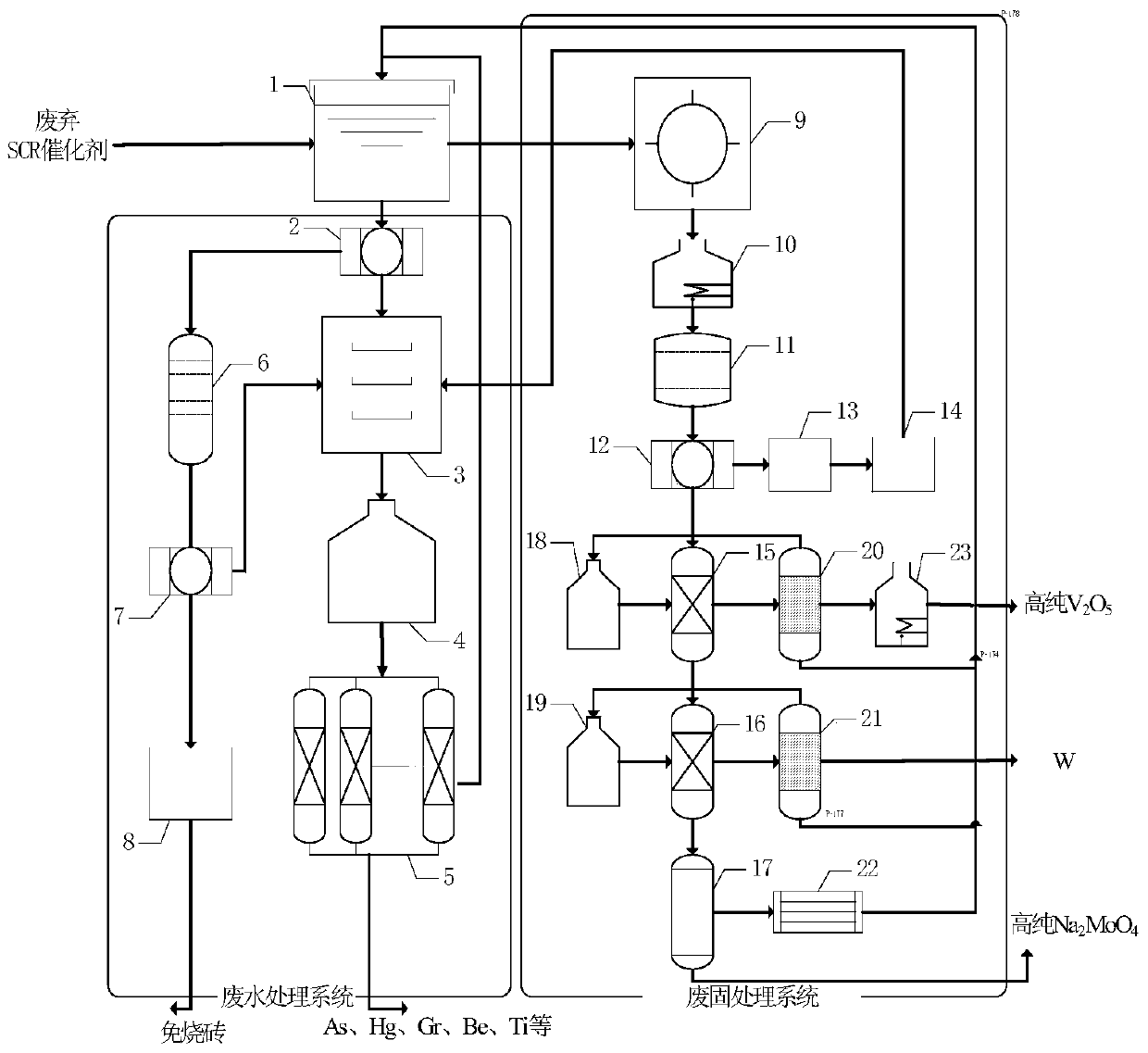

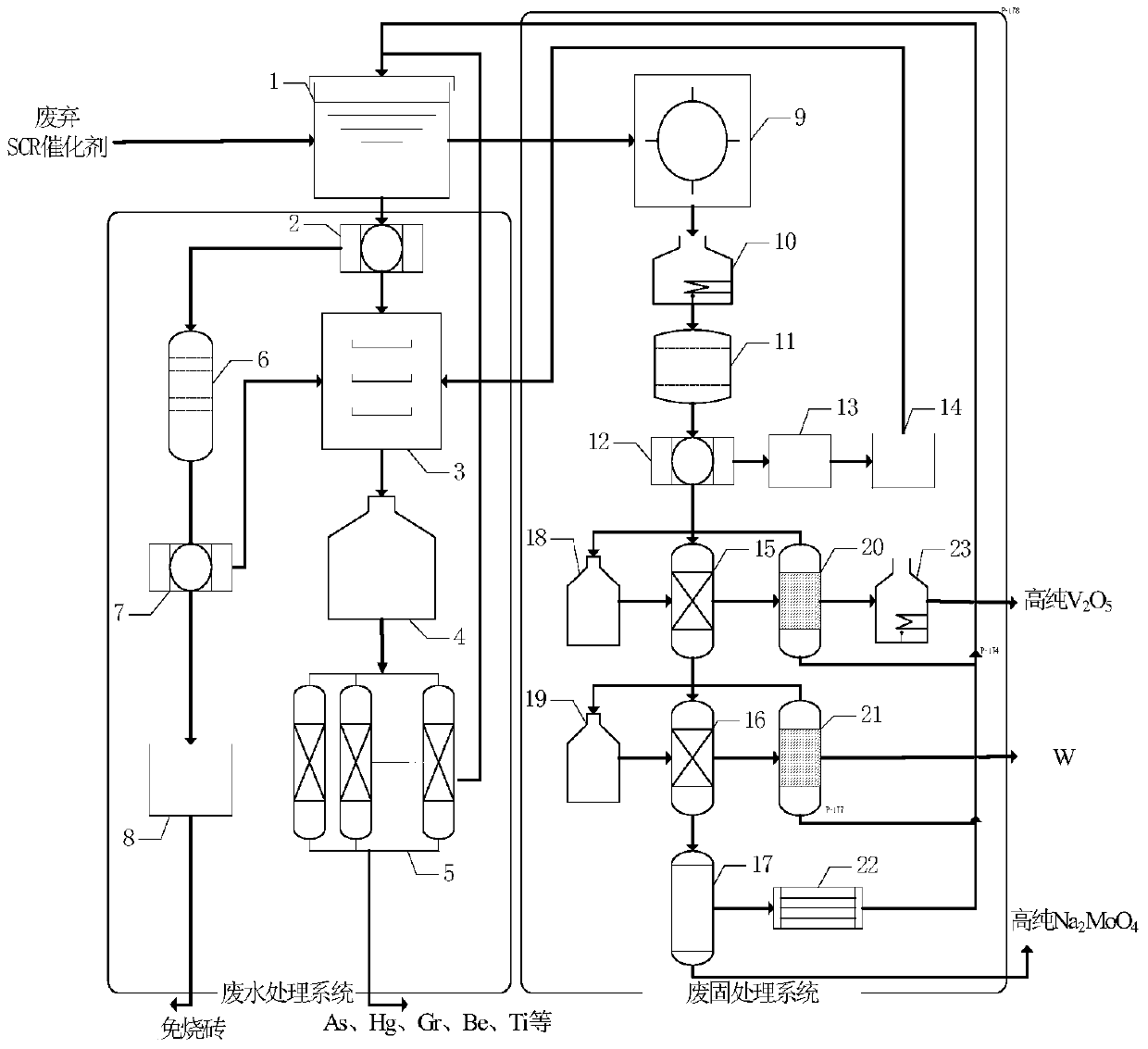

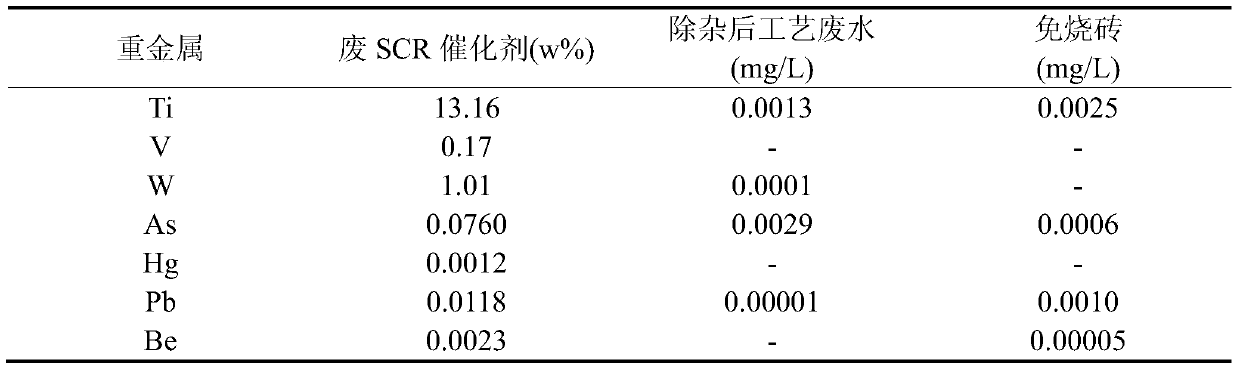

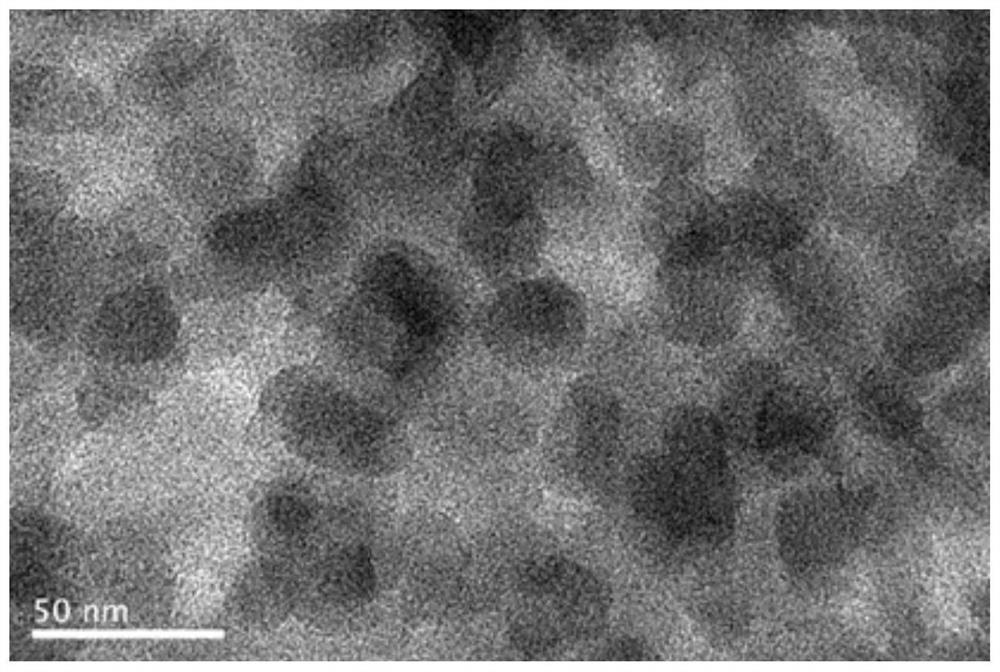

A system for recovering heavy metals from waste scr catalysts and its treatment method

The invention provides a system for recovering heavy metal from waste SCR catalysts and a treatment method thereof. The system comprises an elution system, a waste water treatment system and a waste solid treatment system, wherein a liquid phase outlet of the elution system is connected with the waste water treatment system, and a solid phase outlet of the elution system is connected with the waste solid treatment system. Surface accumulated dust of the waste SCR catalysts are removed through the elution system, high-purity vanadium pentoxide and sodium molybdate are recovered through the waste solid treatment system, and efficient separation of vanadium, tungsten and molybdenum is achieved. Process waste water and elution waste water of the system are enriched through a magnetic nanometer adsorbent in the waste water treatment system, the recycling resource value of toxic and harmful metals in waste water can be greatly improved, and metals such as arsenic, mercury, chromium and thallium in sewage can be recycled. Leaching slag titanium dioxide of the waste solid treatment system is recycled to be used as a magnetic adsorbent carrier in the waste water treatment system. According to the process, secondary waste residues are avoided, waste water is discharged, and the good effect of the closed circulation of various substances in the flue gas denitration industry chain can be achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

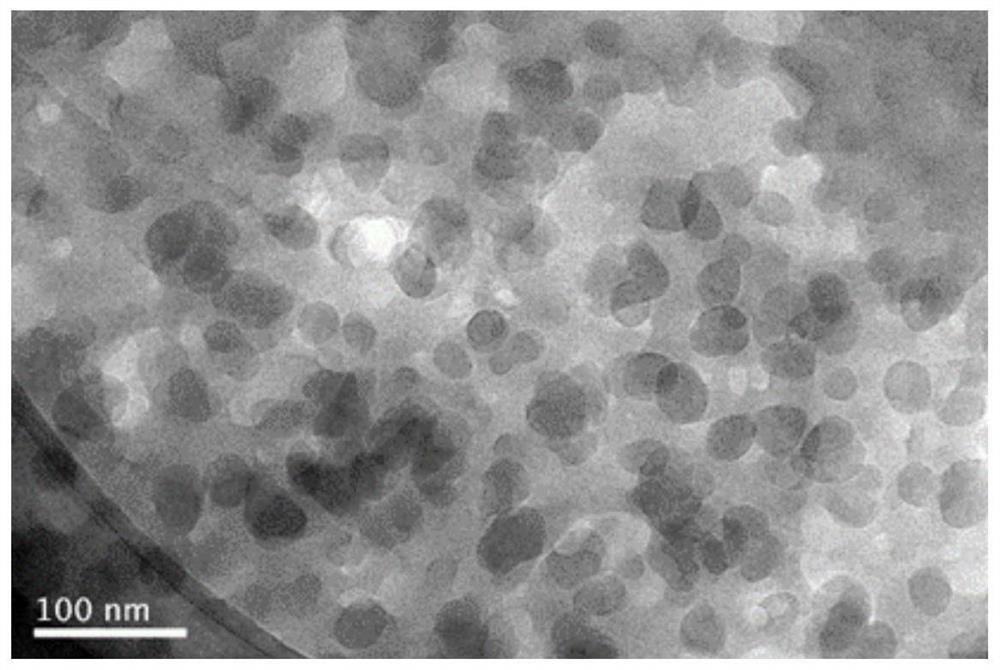

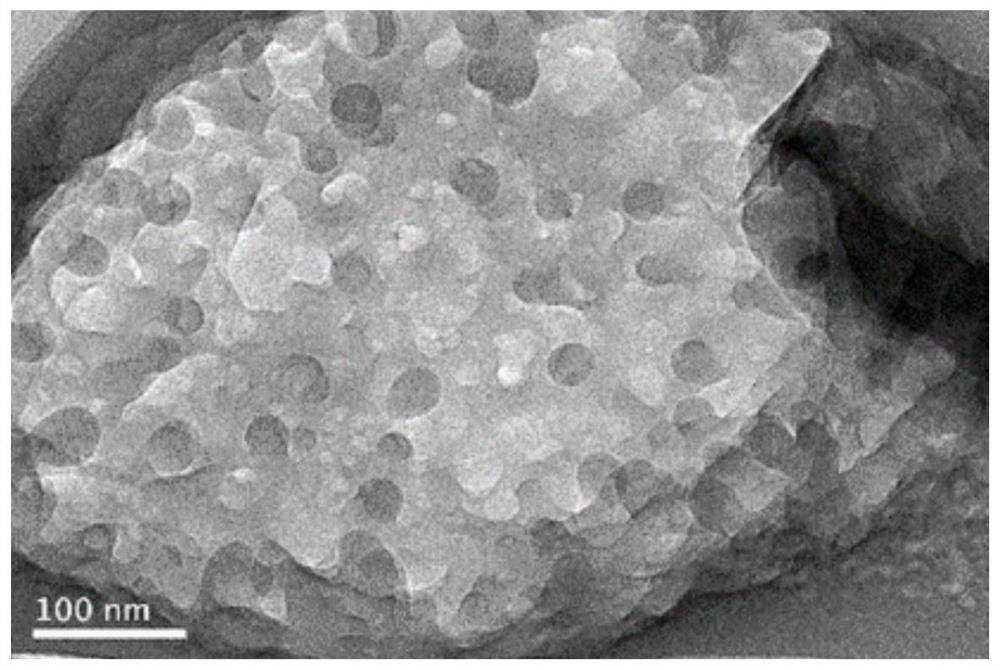

Coal-based graphene quantum dot and preparation method thereof

ActiveCN114426270AReduce manufacturing costIncrease resource valueGraphenePhysical chemistryGraphite

The invention relates to a coal-based graphene quantum dot and a preparation method thereof.The method comprises the steps that a coal-based raw material and excessive nitric acid are mixed, the obtained mixture is subjected to a pre-oxidation reaction, and a pre-oxidation reaction mixture is obtained; carrying out microwave digestion treatment on the pre-oxidation reaction mixture to obtain an oxidation reaction product; and removing nitric acid in the oxidation reaction product, and washing and drying the obtained solid. The conditions of the method provided by the invention can reduce the severity of graphene quantum dots prepared by oxidation reaction, shorten the reaction time, and facilitate high-valued utilization of coal-based raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Collaborative resourceful treatment method and treatment system for oil-based rock debris and kitchen biogas residues

PendingCN114703000ASolve intractableTo achieve a reasonable combinationTransportation and packagingSolid waste disposalOil and greaseSolid fuel

The invention relates to the field of environment-friendly resource utilization, and discloses a collaborative resourceful treatment method and system for oil-based rock debris and kitchen biogas residues. According to the method, the oil-based rock debris is subjected to solid-liquid separation, drying and fine crushing to obtain powder, then the kitchen waste is subjected to screening and solid-liquid separation, obtained grease and solid-phase residues are mixed with the oil-based rock debris powder according to a certain proportion, and finally the mixture is dried, formed and cut into blocks to be made into the solid fuel. According to the treatment system, the oil-based rock debris and the kitchen biogas residues are treated respectively, reasonable combination of the oil-based rock debris and the kitchen biogas residues is achieved, the problem that the oil-based rock debris and the kitchen biogas residues are difficult to treat is well solved, the effects of reduction, harmlessness and recycling can be achieved for the oil-based rock debris and the kitchen biogas residues, the environmental benefits and the economic benefits are obvious, and the method is suitable for industrial production. Not only is the environmental risk of the oil-based rock debris greatly reduced, but also the recycling value of the kitchen biogas residues and the oil-based rock is further improved, and a contribution is made to reduction of carbon emission in China.

Owner:POWERCHINA CHENGDU ENG

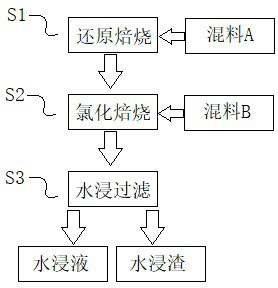

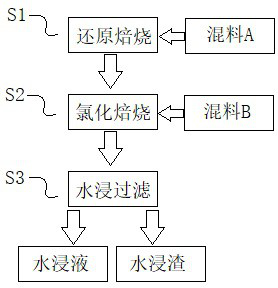

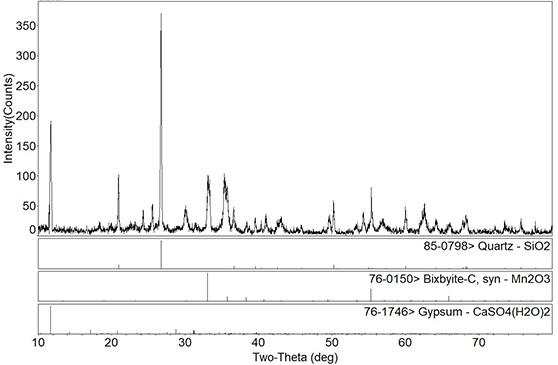

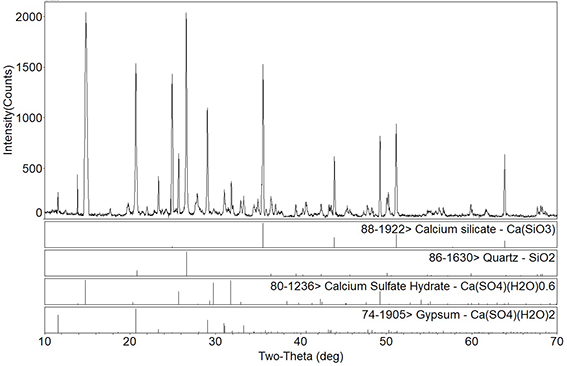

A kind of manganese slag collaborative calcium chloride waste slag recycling treatment method

ActiveCN113387390BEasy to implementControls are responsiveCement productionManganese halidesCalcium silicateSulfate

The invention discloses a manganese slag and calcium chloride waste slag recycling treatment method. The manganese slag and calcium chloride waste slag are roasted in two stages to realize the synergistic recycling method. Calcium chloride, silicon dioxide and water vapor in the air are utilized. The reaction characteristics of calcium silicate and hydrogen chloride are formed at high temperature. The manganese slag containing the low-valent manganese phase formed by reduction roasting is mixed with the above materials to carry out high-temperature chlorination roasting, and the roasted product is separated by water leaching to obtain manganese chloride, and obtain The water leaching residue composed of calcium silicate, calcium sulfate and silica mixture realizes the synergistic utilization of manganese residue and calcium chloride waste residue, improves the resource value of the above solid waste, has high economic benefits, and reduces the For the environmental pollution caused by the separate treatment of the corresponding solid waste, the entire treatment process is simple and easy to implement, and the energy consumption is low, which can be widely used in the electrolytic manganese industry.

Owner:CHANGSHA SCI ENVIRONMENTAL TECH

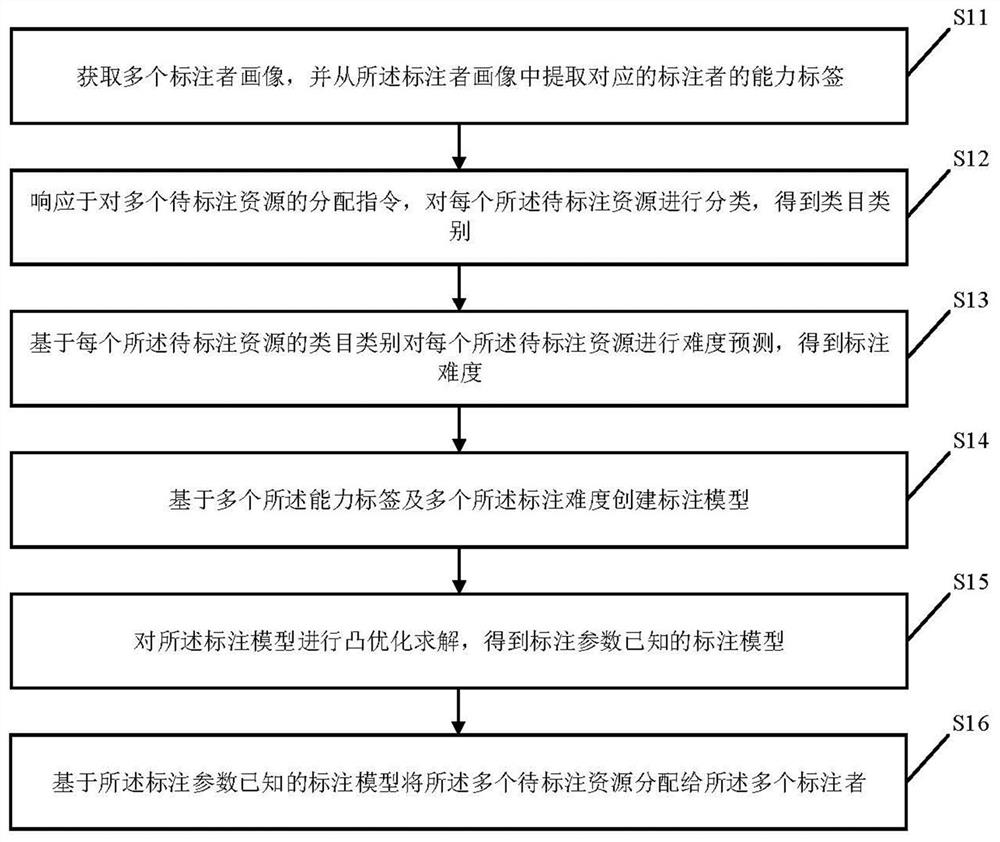

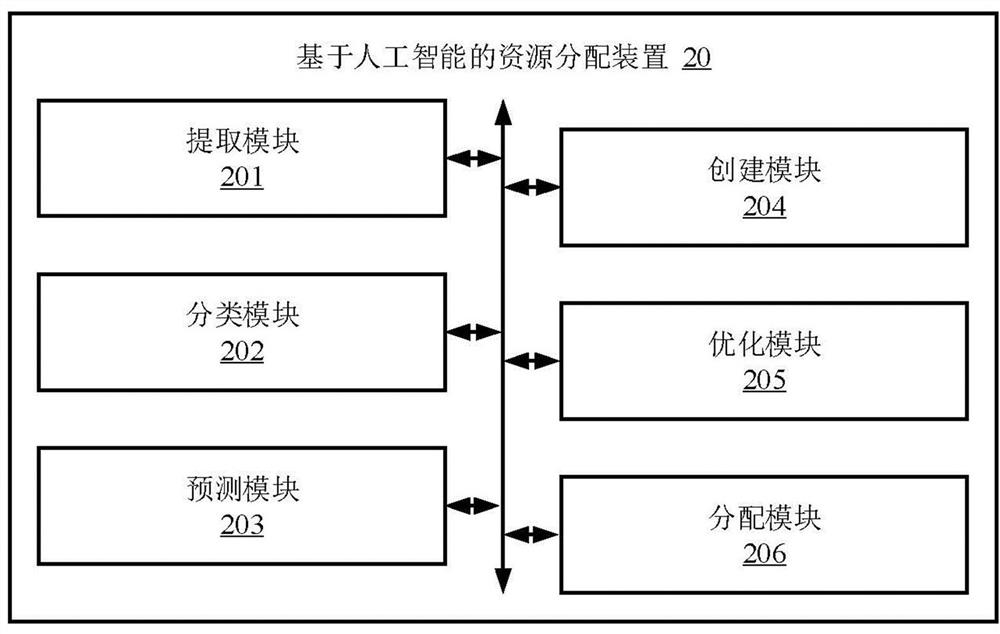

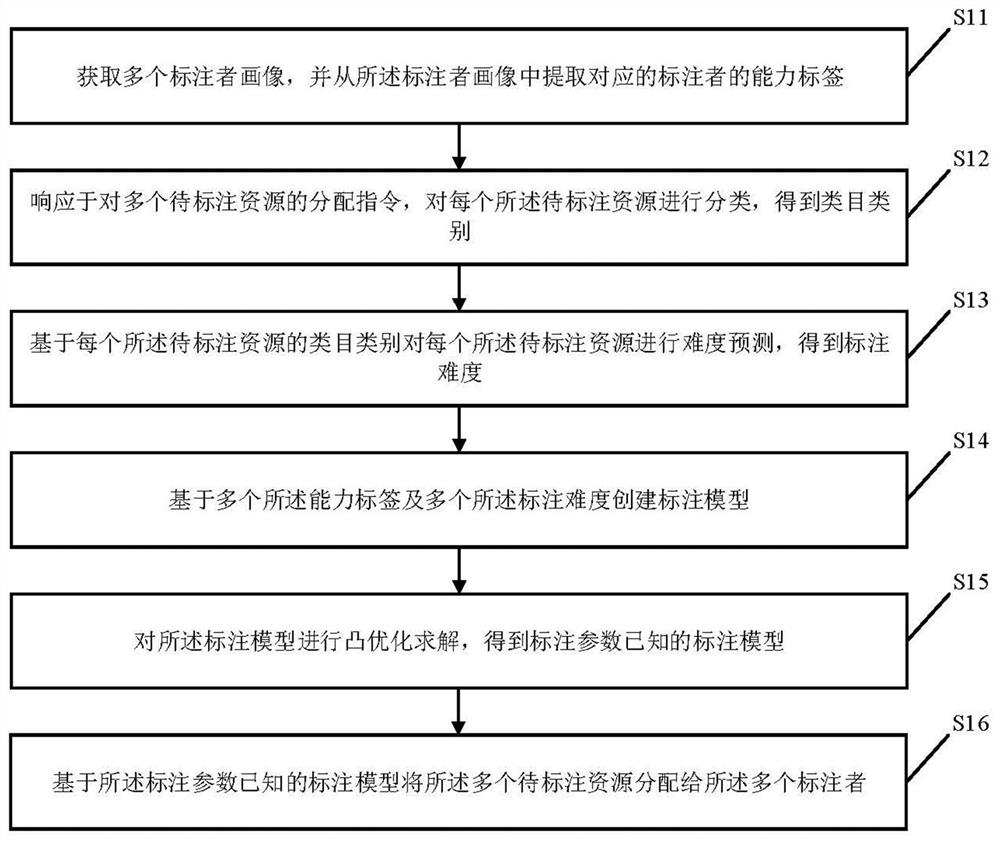

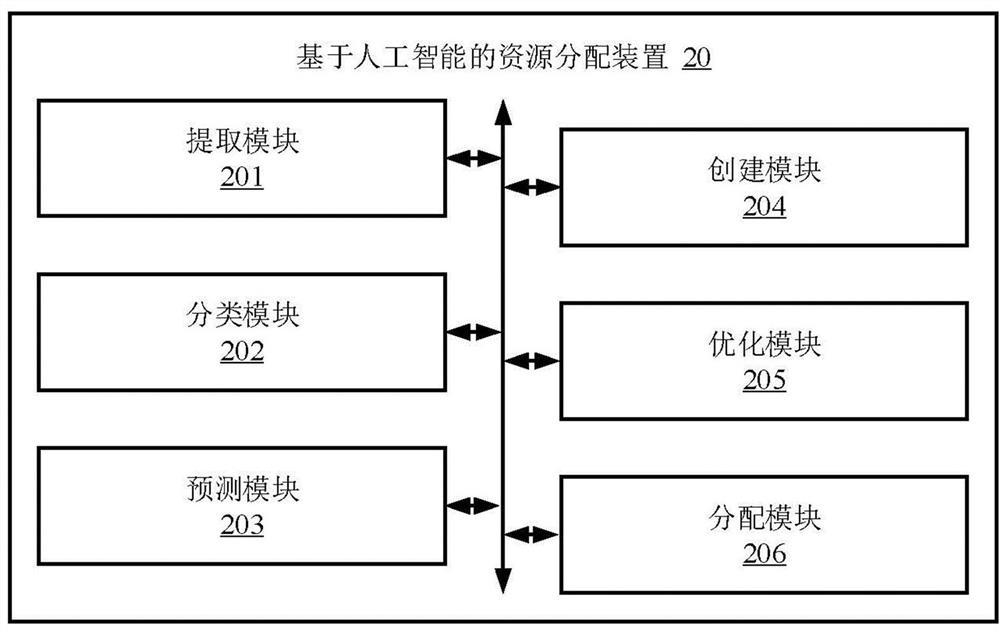

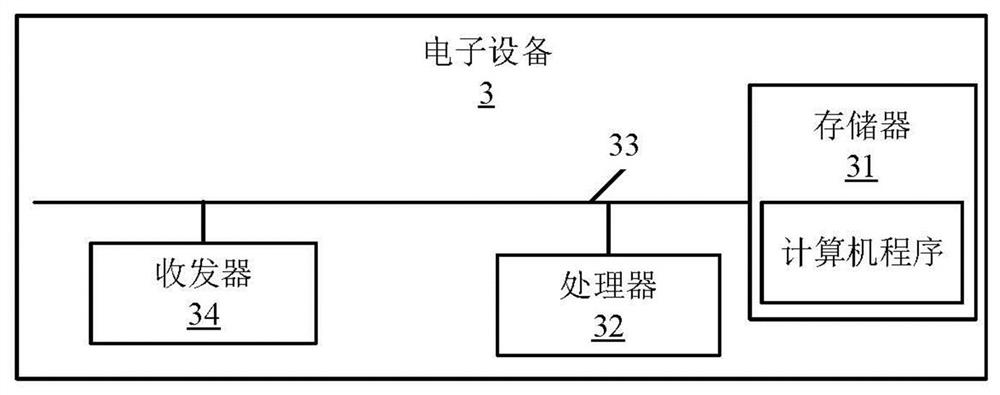

Artificial intelligence-based resource allocation method, device, electronic device, and medium

ActiveCN113570286BIncrease resource valueImprove accuracyResourcesText database queryingResource assignmentAlgorithm

The present invention relates to the field of artificial intelligence technology, and provides an artificial intelligence-based resource allocation method, device, electronic equipment, and medium. When extracting the labeler's ability label from the labeler's portrait and determining the allocation of multiple resources to be marked , by classifying each resource to be labeled to obtain the category category, and then predicting the difficulty of each resource to be labeled based on the category category to obtain the labeling difficulty, which improves the prediction accuracy of labeling difficulty, and then based on multiple capability labels and multiple Create a labeling model with a labeling difficulty, solve the labeling model with convex optimization, and obtain a labeling model with known labeling parameters. Finally, based on the labeling model with known labeling parameters, you can calculate the labeling accuracy of each labeler for labeling resources, so that The resources to be labeled are allocated based on the labeling accuracy. The present invention matches the labeler's ability label with the labeling difficulty of the resources to be marked, thereby improving the accuracy of labeling the resources to be marked.

Owner:PING AN TECH (SHENZHEN) CO LTD

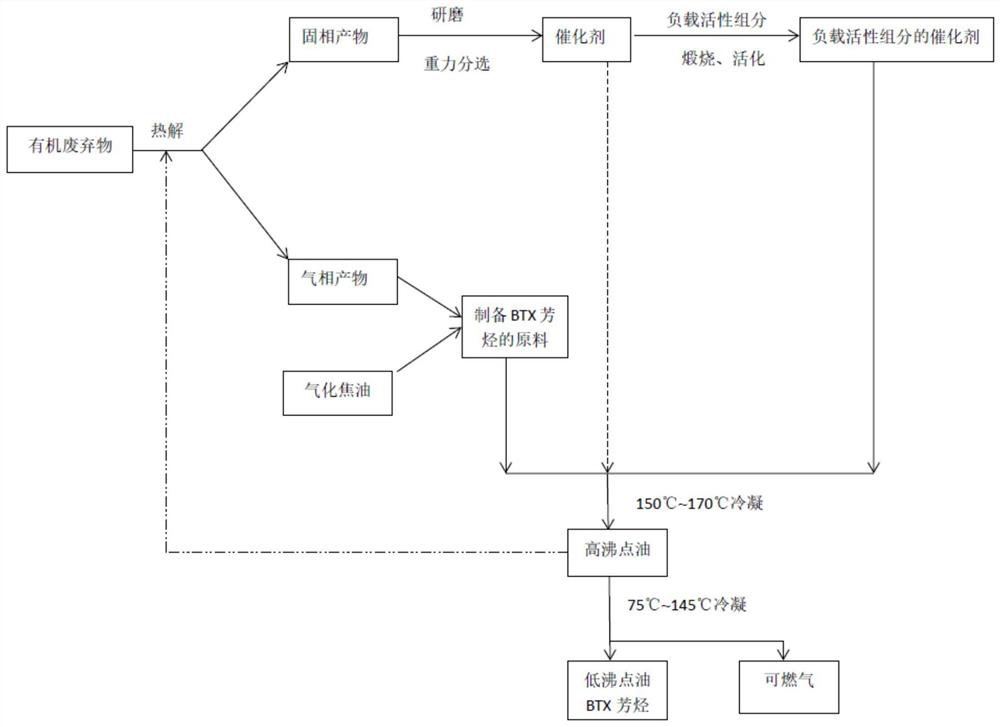

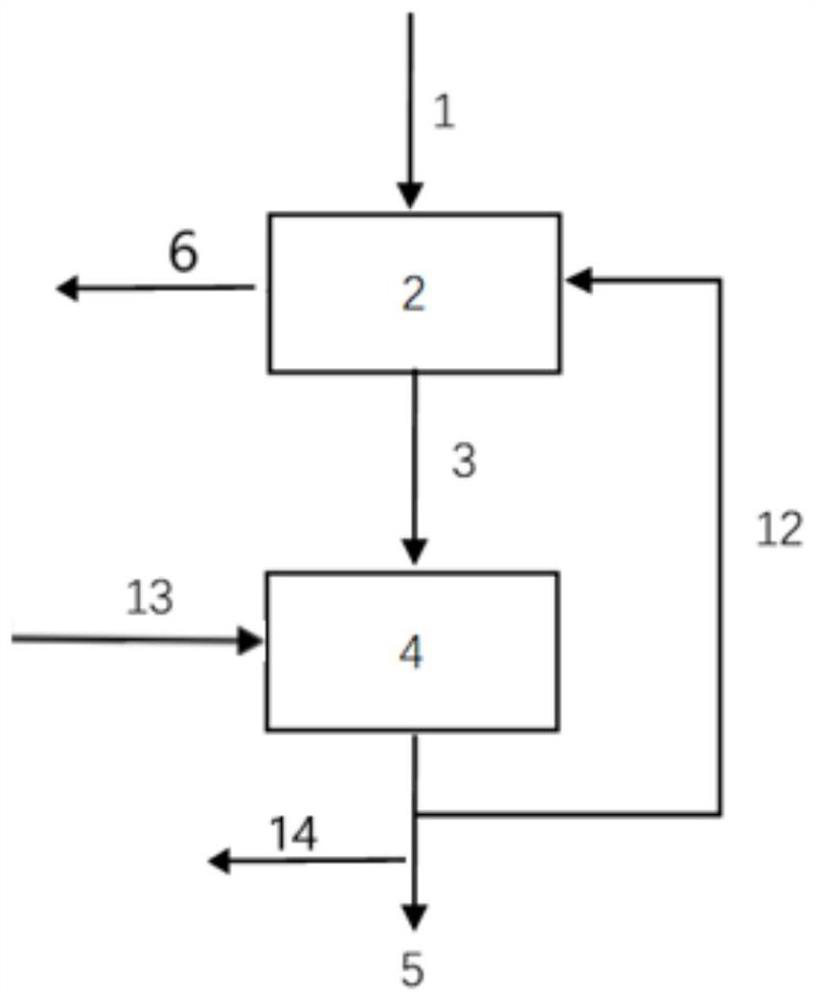

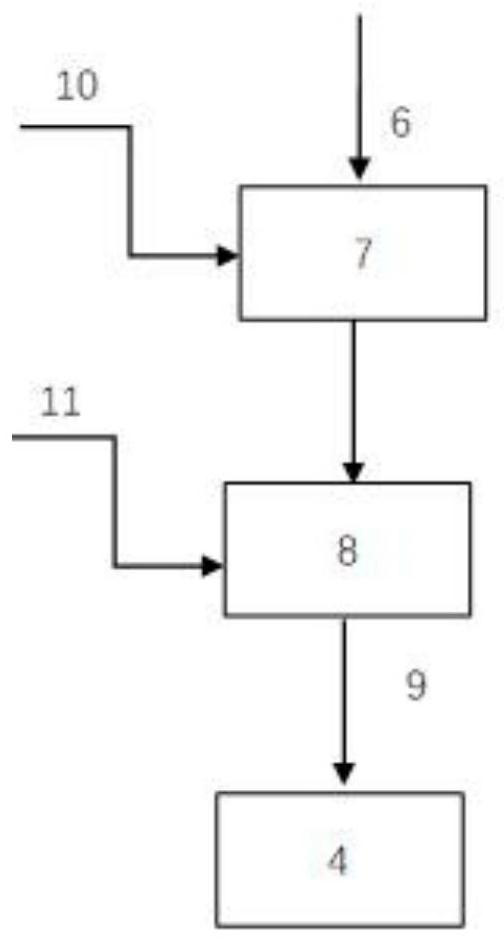

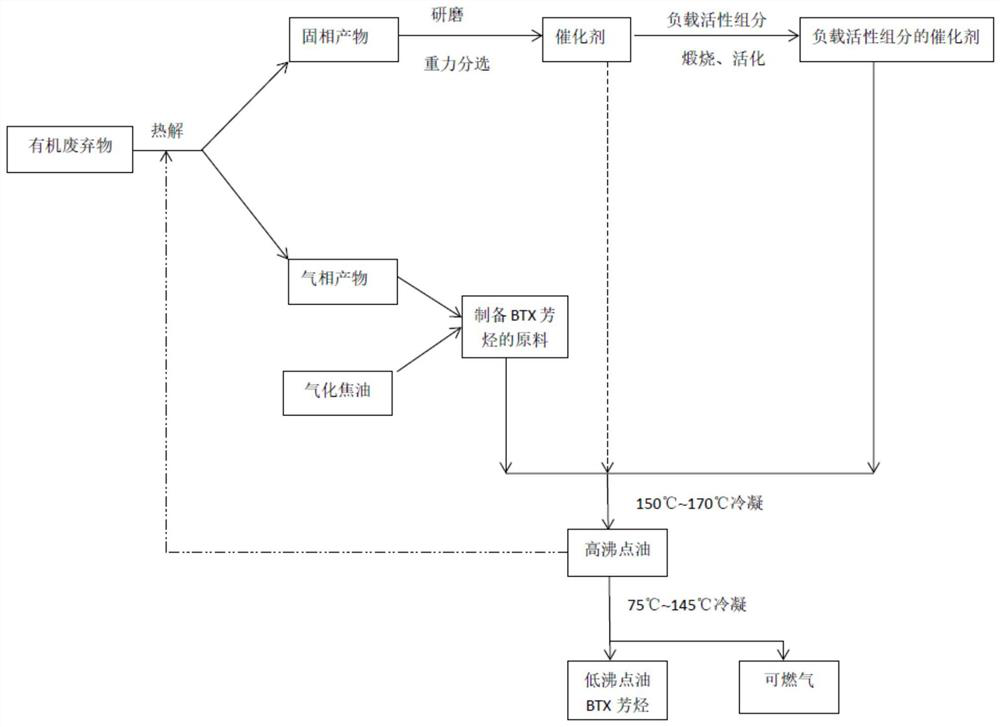

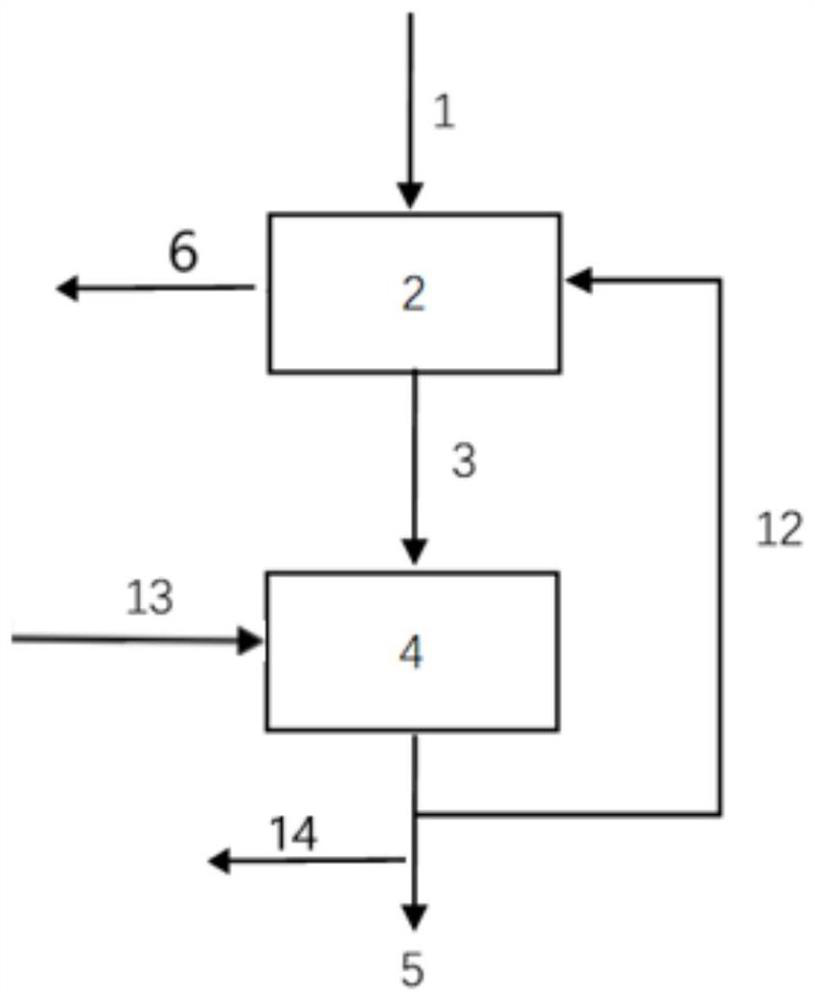

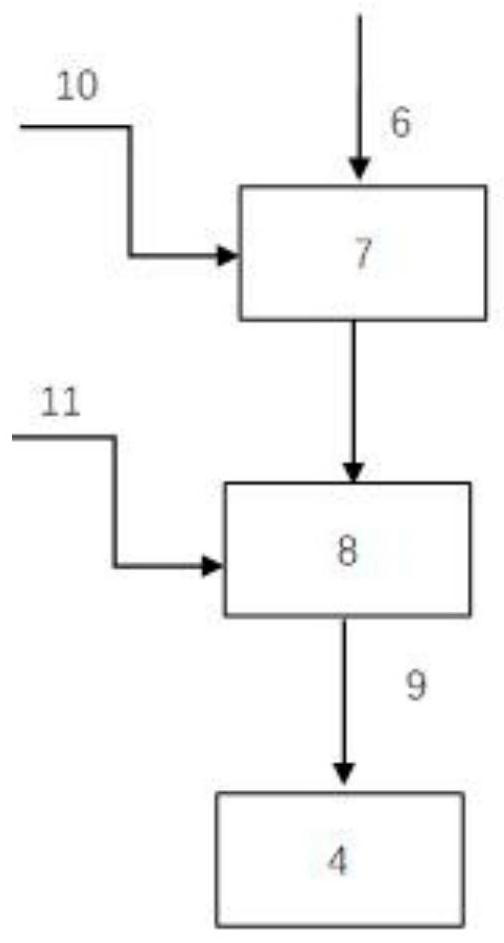

Catalyst for producing BTX aromatic hydrocarbon by using organic waste, preparation method and application thereof, and method for producing BTX aromatic hydrocarbon

ActiveCN112717912AReduce consumptionSimple manufacturing methodProductsReagentsPtru catalystCombustible gas

The invention provides a catalyst for producing BTX aromatic hydrocarbon from organic waste, a preparation method and application of the catalyst, and a method for producing BTX aromatic hydrocarbon. Firstly, the invention provides a preparation method of a catalyst for producing BTX aromatic hydrocarbon by utilizing organic wastes, which comprises the following steps: 1) pyrolyzing the organic wastes to obtain semicoke and volatile matters; and 2) grinding the semicoke, and carrying out gravity separation to obtain carbon powder, thereby obtaining the catalyst. And after the carbon powder is loaded with the active component, the catalyst loaded with the active component is obtained through calcination and activation. Secondly, volatile or gasified tar produced by pyrolysis of organic waste gas is catalytically reacted with the prepared catalyst or catalyst loaded with active components to obtain low boiling tar BTX aromatics, combustible gas and high boiling oil According to the method, organic wastes such as household garbage can be directly changed into high-quality chemical product BTX aromatic hydrocarbon, precious resources such as petroleum, methanol, ethanol, dimethyl ether or n-hexane are not needed, and the resource consumption is reduced.

Owner:TONGJI UNIV

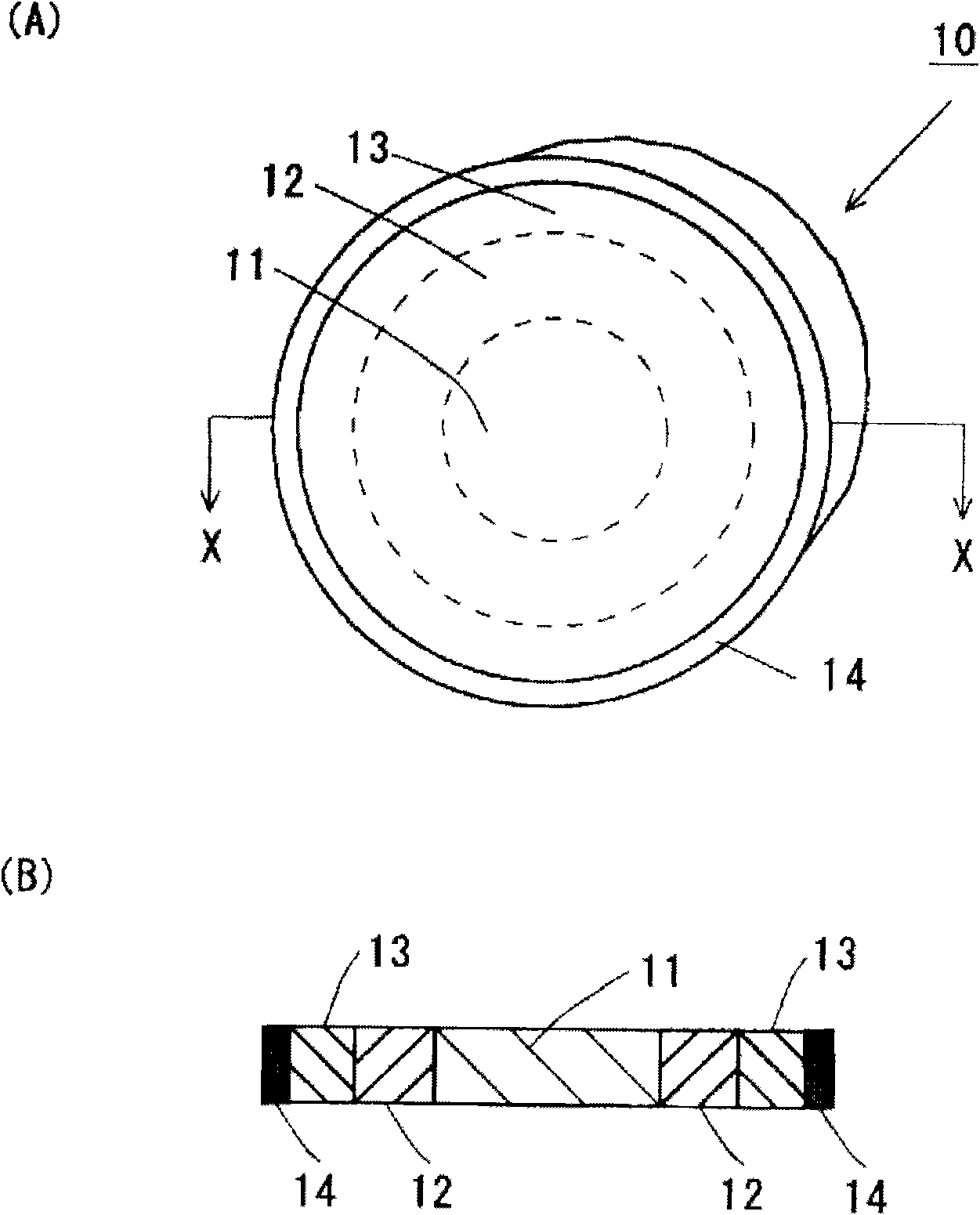

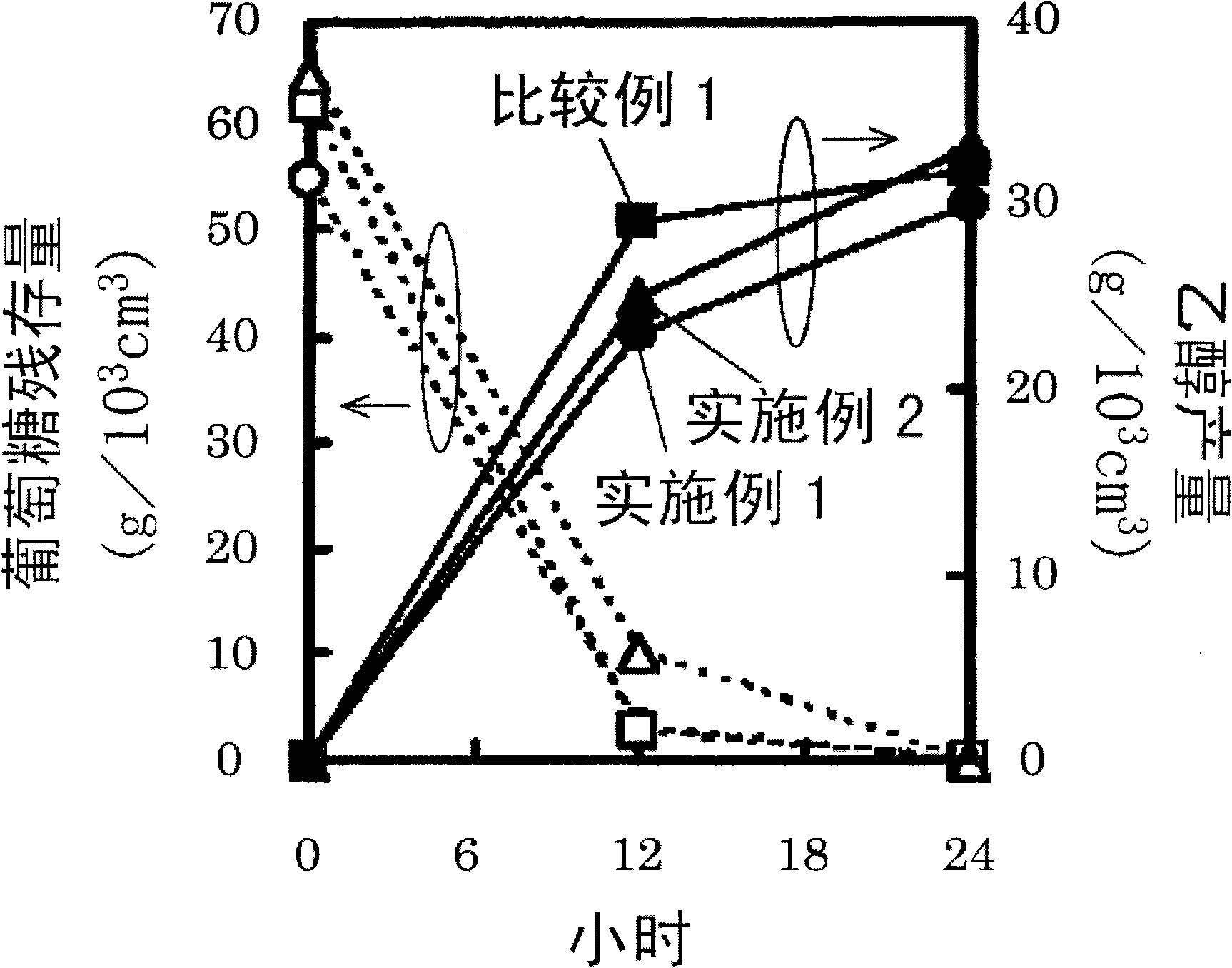

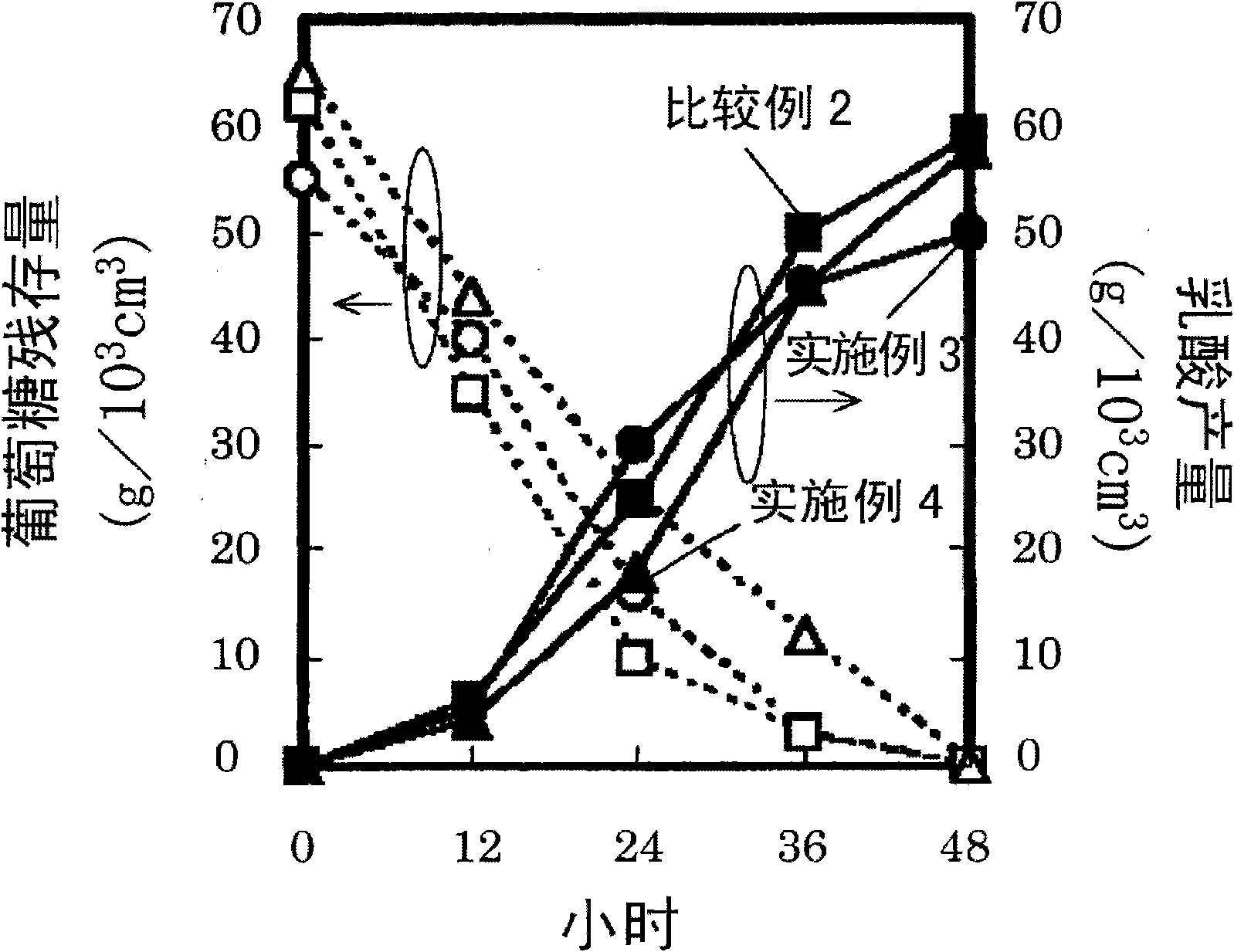

Method for production of ethanol or lactic acid

Disclosed is a method for producing ethanol or lactic acid from a palm trunk with efficiency and at low cost. A sap is extracted from a palm trunk. A fiber of the palm trunk produced after the extraction of the sap is hydrolyzed with an enzyme to saccharify the fiber, thereby producing a saccharified solution. The sap and the saccharified solution are subjected to the fermentation with a microorganism to produce ethanol or lactic acid. As a pretreatment for the saccharification with the enzyme, the fiber of the palm trunk may be hydrolyzed with an acid or alkali. The saccharification by hydrolysis and the fermentation with the microorganism may be carried out simultaneously. In the fermentation with the microorganisms, the saccharified solution (i.e., a hydrolysate of the palm trunk) and the sap may be used in the form of a mixture or separately.

Owner:INDEPENDENT ADMINISTRATIVE INST JAPAN INT RES CENT FOR AGRI SCI +1

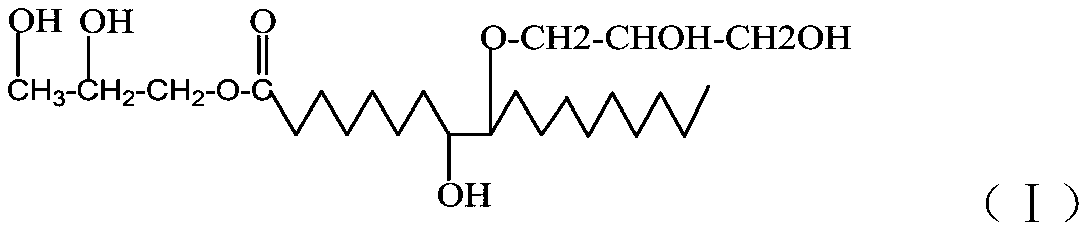

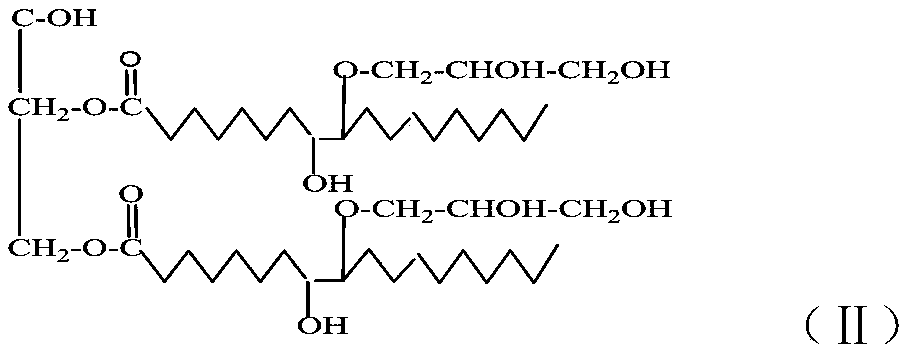

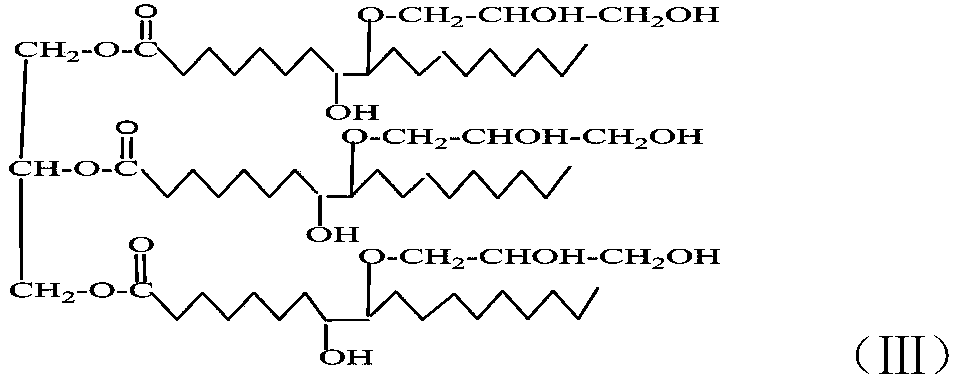

High-functionality mixed polyol initiator and preparation method thereof

The invention relates to a high-functionality mixed polyol initiator and a preparation method thereof. The initiator is a composition of two or three of hydroxy fatty acid monoglyceride, hydroxy fattyacid diglyceride and hydroxy fatty acid triglyceride. Further, the initiator comprises, by weight, 25-50 parts of hydroxy fatty acid monoglyceride, 30-60 parts of hydroxy fatty acid diglyceride and 5-15 parts of hydroxy fatty acid triglyceride. The preparation method includes the steps: (1) adding epoxy fatty acid grease and glycerol with the weight ratio of 1:(0.2-0.6) in nitrogen or inert gas shielding atmosphere, and performing reaction under the action of base catalysis at the temperature 130-250 DEG C under the pressure of 0.1-0.3MPa for 3-15 hours; (2) removing water and other small molecular weight impurities in a vacuum-pumping manner, and filtering solid insoluble substances to obtain the initiator. The initiator is applied to rigid polyurethane foam polyether polyols, the strength of rigid foam products can be improved, and shrinkage in the production process is decreased.

Owner:广州市友聚米新材料有限公司

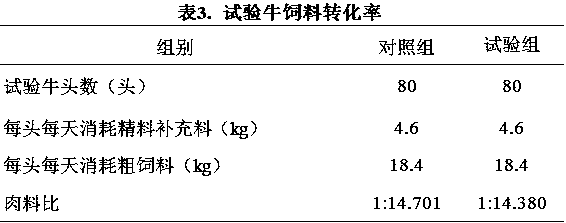

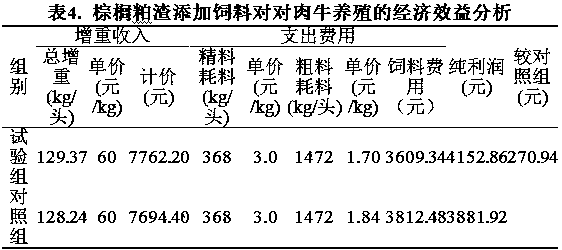

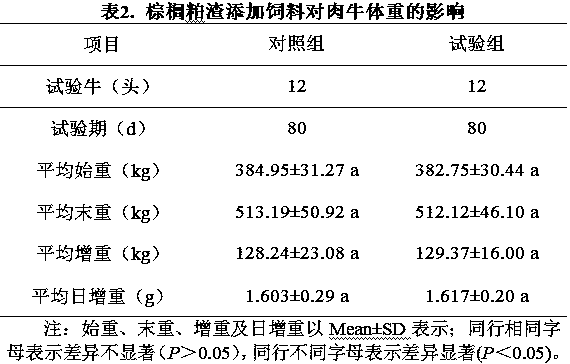

Cattle feed containing palm meal residue, and preparation method of cattle feed

InactiveCN109497302AImprove conversion ratePromote growth and developmentAnimal feeding stuffAgricultural scienceEconomic benefits

The invention discloses cattle feed containing palm meal residue, and a preparation method of the cattle feed. The preparation method comprises the steps of carrying out anaerobic fermentation on palmoil extraction kernel residue, used as a substrate, by using lactic acid bacteria and saccharomyces cerevisiae, expanding the basic number of a bacterial colony, then mixing the palm oil extraction kernel residue with an empty fruit bundle and a base material for carrying out secondary anaerobic fermentation, using the product to replace part of corn stalks and other forages and adding into cattle roughage, and evenly stirring to obtain the cattle feed. The obtained cattle feed can promote the growth of beef cattle, reduce the cattle feed production cost, improve the economic benefit of cattle raising, and realizes the higher value application of meal residue obtained after palm oil extraction.

Owner:甘肃省轻工研究院有限责任公司

A kind of catalyst for producing btx aromatic hydrocarbons by utilizing organic waste and its preparation method and use, and the method for producing btx aromatic hydrocarbons

ActiveCN112717912BReduce consumptionSimple manufacturing methodProductsReagentsPtru catalystCombustible gas

The invention provides a catalyst for producing BTX aromatic hydrocarbons by utilizing organic waste, a preparation method and application thereof, and a method for producing BTX aromatic hydrocarbons. First, a method for preparing a catalyst for producing BTX aromatic hydrocarbons from organic wastes is provided, comprising the following steps: 1) pyrolyzing the organic wastes to obtain semi-coke and volatile matter; 2) grinding the semi-coke and obtaining by gravity separation Carbon powder, the catalyst is obtained. After the carbon powder is loaded with active components, it is calcined and activated to obtain a catalyst loaded with active components. Secondly, the gas phase product volatiles or gasification tar produced by the pyrolysis of organic waste gas are catalytically reacted with the prepared catalyst or the catalyst loaded with active components to obtain low-boiling tar BTX aromatics, combustible gas and high-boiling oil. The present invention can directly turn organic wastes such as household waste into high-quality chemical products BTX aromatics, does not require valuable resources such as petroleum, methanol, ethanol, dimethyl ether or n-hexane, and reduces resource consumption.

Owner:TONGJI UNIV

Resourceful treatment method for manganese slag and calcium chloride waste residues

ActiveCN113387390AEasy to implementControls are responsiveCement productionManganese halidesCalcium silicateSulfate

The invention discloses a resourceful treatment method for manganese slag and calcium chloride waste residues, the resourceful treatment method is a method for realizing synergistic resourceful treatment through two-stage roasting of manganese slag and calcium chloride waste residues and utilizes the reaction characteristic that calcium chloride, silicon dioxide and water vapor in air form calcium silicate and hydrogen chloride at high temperature, manganese slag which is formed through reduction roasting and contains a low-valence manganese phase is mixed with the materials to be subjected to high-temperature chloridizing roasting, the roasted product is subjected to water leaching separation to obtain manganese chloride, water leaching slag composed of the mixture of calcium silicate, calcium sulfate and silicon dioxide is obtained, and collaborative resource utilization of the manganese slag and calcium chloride waste slag is achieved; the method improves the resource value of the solid waste, has higher economic benefits, also reduces the environmental pollution caused by independent treatment of the corresponding solid waste, and the whole treatment process is simple and feasible in steps, low in energy consumption and capable of being widely popularized and applied in the electrolytic manganese industry.

Owner:CHANGSHA SCI ENVIRONMENTAL TECH

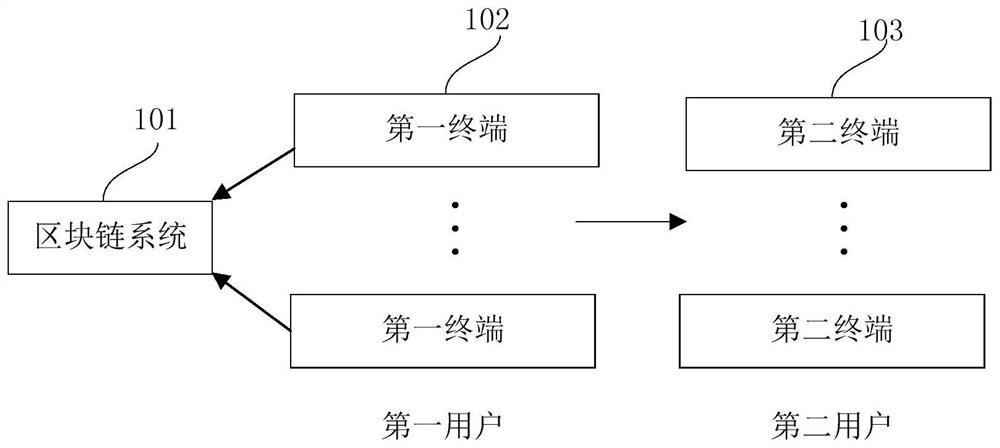

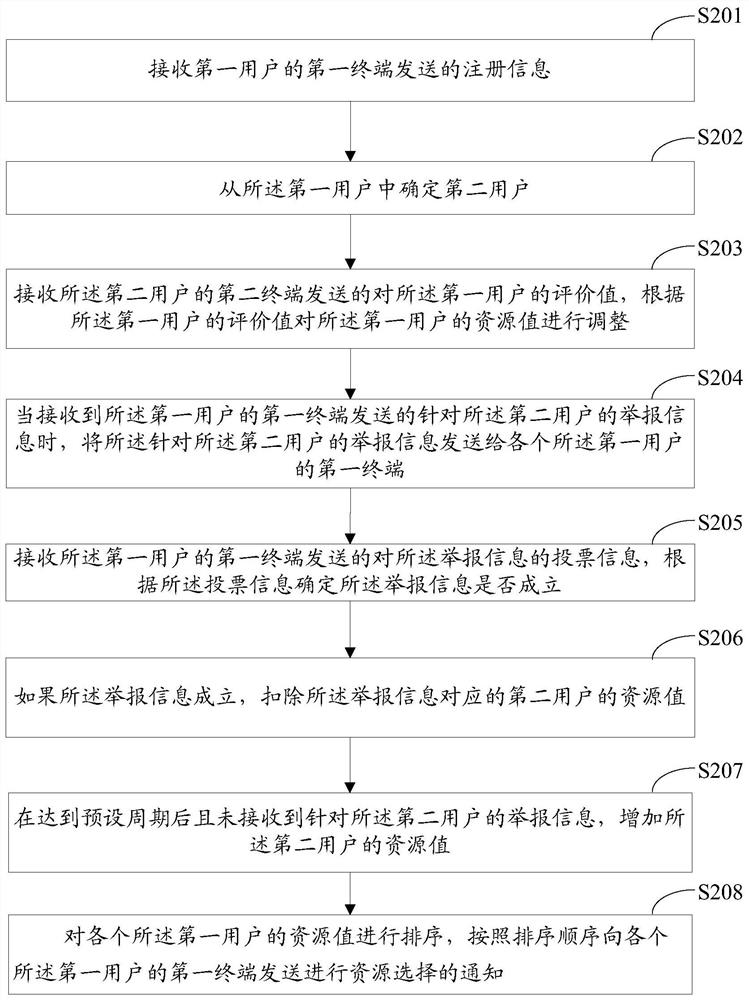

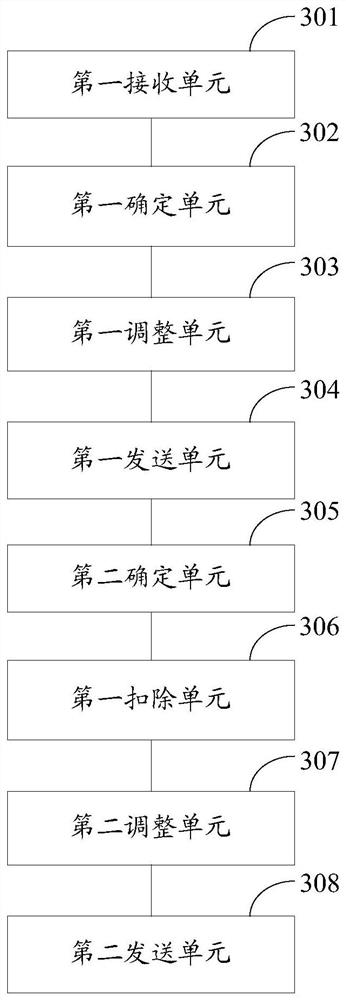

Information management method and device based on blockchain

ActiveCN112036949AImprove management efficiencyIncrease resource valueDatabase distribution/replicationSpecial data processing applicationsComputer networkEngineering

The invention discloses an information management method and device based on a blockchain, applied to a blockchain system, and the method comprises the steps: receiving registration information of first users; determining a second user from the first users; receiving an evaluation value of the second user to the first users, and adjusting a resource value of the first users according to the evaluation value of the first users; sending denounced information of the first users for the second user to each first user; receiving voting information of the first user for the denounced information, and determining whether the denounced information is true or not according to the voting information; if so, deducting the resource value of the second user corresponding to the denounced information; after a preset period arrives and no denounced information for the second user is received, increasing a resource value of the second user; and sorting the resource values of the first users, and sending a notification of resource selection to the first users according to a sorting sequence. Therefore, the information management efficiency is improved, and dynamic evaluation and management of eachuser are realized.

Owner:BANK OF CHINA

Preparation method of industrial silicon smelting reducer

ActiveCN103803552BHigh mechanical strengthLow impurity contentSilicon compoundsMolding machineAnthracite

Owner:云南永昌硅业股份有限公司

Resource allocation method and device based on artificial intelligence, electronic equipment and medium

ActiveCN113570286AIncrease resource valueImprove accuracyResourcesText database queryingAlgorithmEngineering

The invention relates to the technical field of artificial intelligence, and provides a resource allocation method and device based on artificial intelligence, electronic equipment and a medium, and the method comprises the steps: extracting a capability label of a tagger from a tagger portrait, and when determining to allocate a plurality of to-be-tagged resources, classifying each to-be-tagged resource to obtain a category, therefore, difficulty prediction is carried out on each to-be-labeled resource based on the category to obtain the labeling difficulty, the prediction accuracy of the labeling difficulty is improved, then a labeling model is established based on the multiple capability labels and the multiple labeling difficulties, convex optimization solution is carried out on the labeling model, and the labeling model with known labeling parameters is obtained. And finally, on the basis of a labeling model with known labeling parameters, the labeling accuracy of each labeling person on the to-be-labeled resources can be calculated, so that the to-be-labeled resources are allocated on the basis of the labeling accuracy. According to the method and the device, the capability label of the tagger is matched with the tagging difficulty of the to-be-tagged resource, so that the accuracy of tagging the to-be-tagged resource is improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

Biological drying method for life garbage

ActiveCN100445676CReduce latent heat lossReduce moisture contentDrying solid materials without heatEngineeringCompost

A biologic method to drying life garbage, it is about a kind of technology to decrease the water of life garbage and biologic stable disposal. Firstly, after sieving out the big block from the life garbage, to stack it into groove-shape compost reactor, then to cover tying straw pad and compound heat insulating coiled material, to bonds the opening rubber tail gas gathering tube with the cooling tube under the coiled material. The cooling tube is connected with gas-liquid separator, centrifugal blast blower B, gas separation unit and centrifugal blast blower A sequentially, and the centrifugal A is connected with the bottom of the reactor. Secondly, to vent the air fitfully and circularly with firm discharge, to turn one time on the second day and the fourth day respectively, to complete drying in six days, offgas enters gas separation unit after liquor condensate is eliminated by the cooling tube and gas-liquid separator, after discharging part of offgas into off-odor unit, to supply equivalent clean air, then to put the offgas into the centrifugal A for garbage venting. The quantity of offgas off odor and running cost of this invention is low, the water-content coefficient of the garbage is smaller than 40% after disposal, and it can be used for drying the life garbage with water-content coefficient 60%.

Owner:TONGJI UNIV

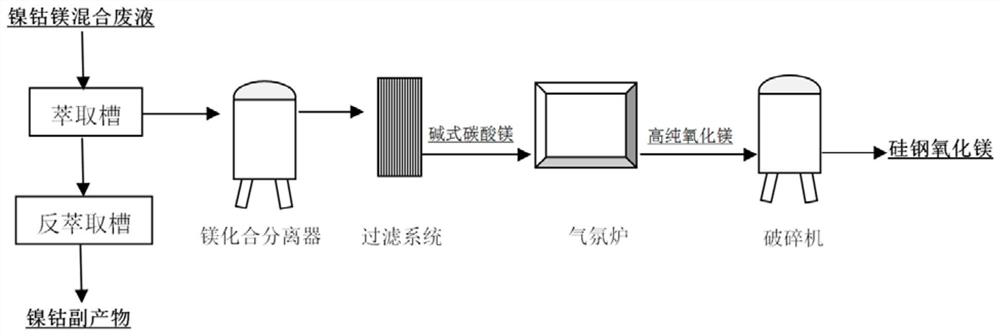

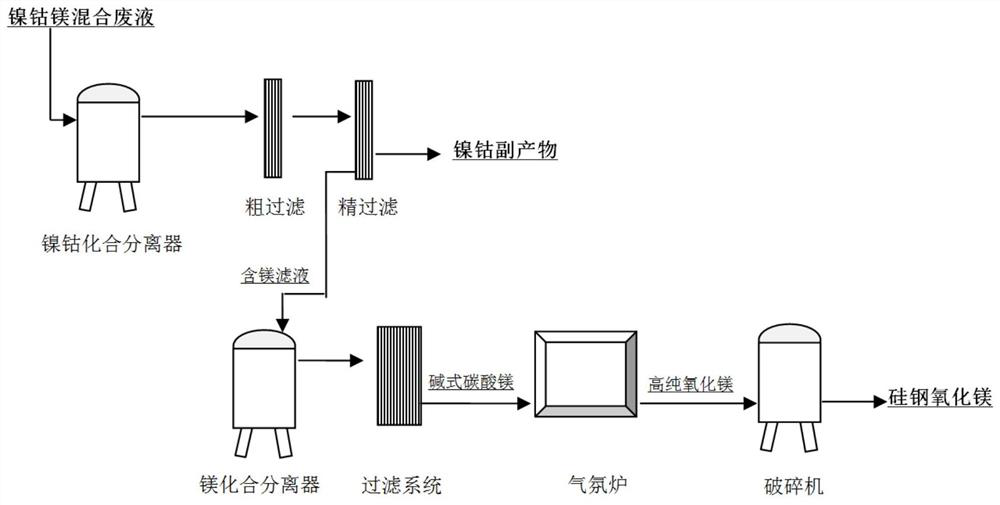

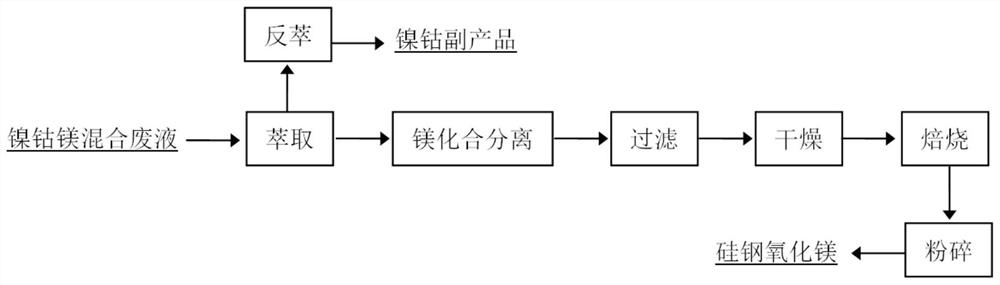

Device and method for recovering nickel and cobalt and co-producing magnesium oxide from nickel-cobalt-magnesium waste liquid

ActiveCN110438338BHigh economic valueEfficient separationProcess efficiency improvementMagnesiaSulfidationCobalt

The invention provides a device and method for recovering nickel and cobalt from nickel-cobalt-magnesium waste liquid and co-producing magnesia. The device includes a nickel-cobalt separation and recovery system, a magnesium compound separation and recovery system, an atmosphere roasting furnace and Crusher. The method comprises: firstly separating and recovering nickel-cobalt from nickel-cobalt-magnesium waste liquid by extraction method or sulfidation precipitation method to obtain magnesium-containing solution; then adding bicarbonate and ammonia water to the magnesium-containing solution, stirring, heating, heat preservation and filtering to obtain basic magnesium carbonate; then drying the basic magnesium carbonate and roasting in an atmosphere to obtain high-purity magnesium oxide; finally crushing the high-purity magnesium oxide to obtain silicon steel magnesium oxide products. Through the innovative design, combination and precise control of equipment, the present invention realizes the efficient separation of nickel and cobalt and the low-cost preparation of high-purity magnesium oxide products, and realizes the economical and efficient utilization of nickel-cobalt-magnesium waste liquid resources, which has a very broad market prospects.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com