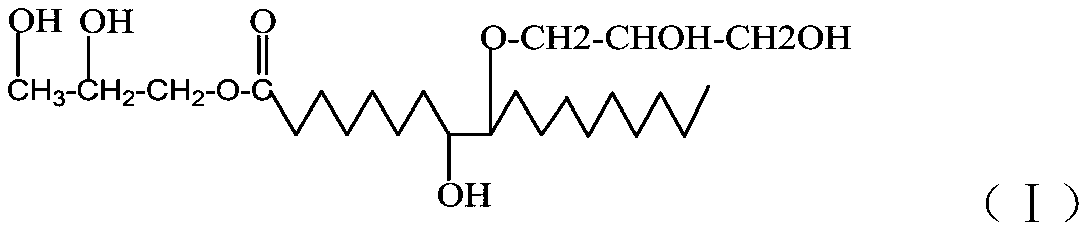

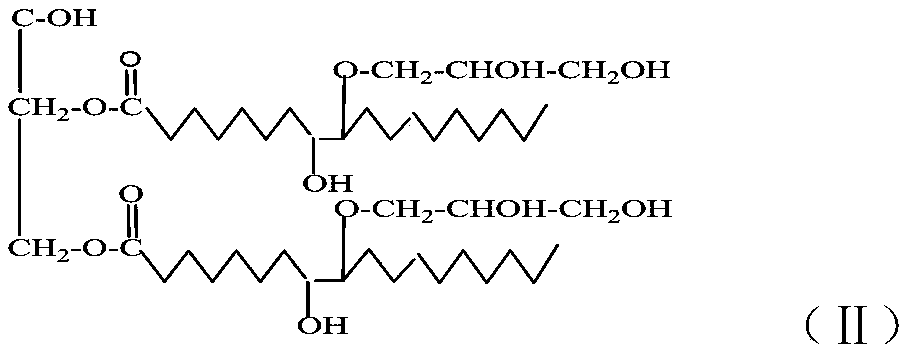

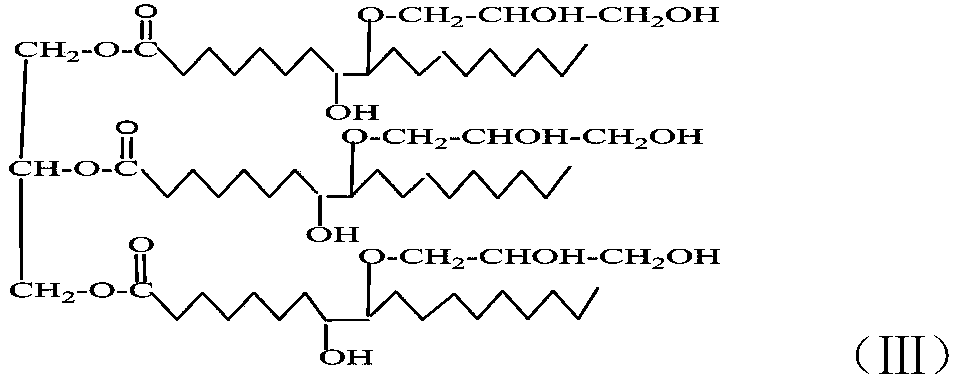

High-functionality mixed polyol initiator and preparation method thereof

A mixed polyol, high-functionality technology, applied in the field of high-functionality mixed polyol starter and its preparation, can solve problems that have not yet been discovered, and achieve the effect of increasing the value of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take 500g of epoxy fatty acid oil mixture, 150g of glycerin, and 12g of sodium methoxide catalyst into a 1L stirring reaction device, evacuate and replace with nitrogen for 3 times, close the valve and stir to raise the temperature to 138°C, set the pressure to 0.2MPa, and react for 10 hours.

[0036] After cooling down to 130°C, add 40g of sorbitan, then raise the temperature to 200°C, set the pressure to 0.2MPa, and react for 4 hours; Functionality mixed polyol, yield 99.8%, hydroxyl value 510mgKOH / g, water 0.2%, average functionality 5.5.

[0037] In the gained polyol initiator, the content of each material is: hydroxy fatty acid monoester 25.6%, hydroxy fatty acid diglyceride 50.2%, hydroxy fatty acid glyceride 13.8%, sorbitol fatty acid monoglyceride 7.2%, sorbitol 0.2%, Glycerin 0.6%, epoxy fatty acid oil 0.2%, water 0.2%, impurities and by-products 2%.

Embodiment 2

[0039] Take 400g of epoxy fatty acid oil mixture, 180g of glycerin, and 7g of sodium ethoxide catalyst into a 1L stirring reaction device, evacuate nitrogen for 3 times, close the valve and stir to raise the temperature to 250°C, set the pressure to 0.25MPa, and react for 3 hours.

[0040]After cooling down to 140°C, add 15g of sorbitan, then raise the temperature to 235°C, set the pressure to 0.2MPa, and react for 6 hours; Functionality mixed polyol, yield 99.76%, hydroxyl value 565mgKOH / g, water 0.1%, average functionality 5.4.

[0041] In the gained polyol initiator, the content of each material is: hydroxy fatty acid monoester 28.3%, hydroxy fatty acid diglyceride 54.9%, hydroxy fatty acid glyceride 10%, sorbitol fatty acid monoglyceride 3.8%, sorbitol 0.5%, Glycerin 0.6%, water 0.1%, impurities and by-products 1.8%.

Embodiment 3

[0043] Add 400g of epoxy fatty acid oil, 140g of glycerol, and 10.8g of sodium methoxide catalyst into a 1L stirring reaction device, evacuate and replace with nitrogen for 3 times, close the valve and stir to raise the temperature to 165°C, set the pressure to 0.2MPa, and react for 5 hours.

[0044] After cooling down to 142°C, add 50g of sorbitan, then raise the temperature to 182°C, set the pressure to 0.2MPa, and react for 10 hours; after the reaction, vacuumize to remove moisture and other small molecular impurities, and filter out solid insoluble matter, with a yield of 99.64 %, hydroxyl value 558mgKOH / g, water 0.2%, average functionality 5.8.

[0045] In the gained polyol initiator, the content of each material is: hydroxy fatty acid monoester 28.3%, hydroxy fatty acid diglyceride 44.8%, hydroxy fatty acid glyceride 13.4%, sorbitol fatty acid monoglyceride 6.5%, sorbitol 2.7%, Glycerin 1.3%, epoxy fatty acid oil 0.3%, water 0.2%, impurities and by-products 2.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com