Device and method for recovering nickel and cobalt and co-producing magnesium oxide from nickel-cobalt-magnesium waste liquid

A nickel-cobalt-magnesium and magnesium oxide technology, applied in the chemical industry, can solve the problems of no efficient separation and recovery device or method, unstable product quality, less magnesium oxide products, etc., to achieve improved physical and chemical properties, low cost and high economic value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

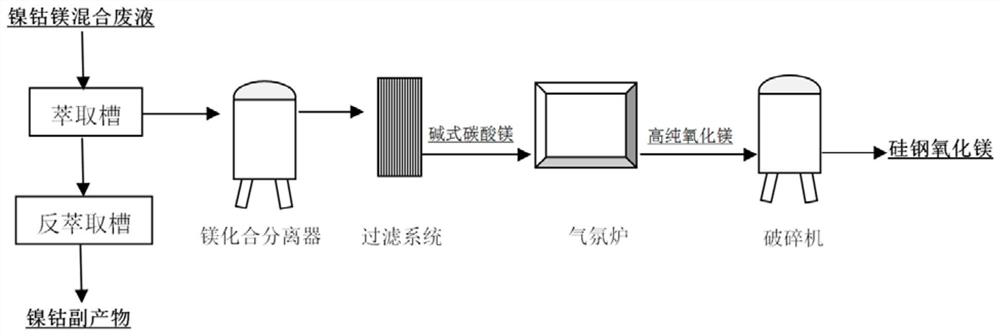

[0060] The device for recovering nickel and cobalt and co-producing magnesium oxide from nickel-cobalt-magnesium waste liquid provided in this embodiment includes a nickel-cobalt separation and recovery system, a magnesium compound separation and recovery system, an atmosphere roaster and a depolymerization crusher connected in sequence.

[0061] The nickel-cobalt separation and recovery system is a nickel-cobalt extraction and separation device; the magnesium compound separation and recovery system includes a magnesium compound separator and a filter system; the nickel-cobalt separation and recovery system is connected to the filter system through a magnesium compound separator; The compound separator is connected with the atmosphere roaster through a filter system; the nickel-cobalt extraction and separation device includes an extraction tank and a stripping tank, one end of the extraction tank is connected to the stripping tank, and the other end is connected to the magnesium...

Embodiment 2

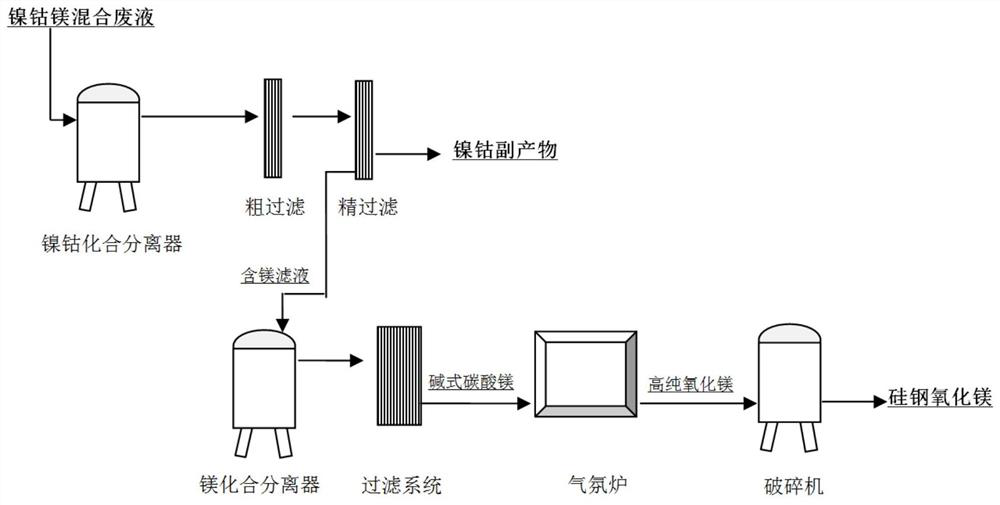

[0064] The device for recovering nickel and cobalt and co-producing magnesium oxide from nickel-cobalt-magnesium waste liquid provided in this embodiment includes a nickel-cobalt separation and recovery system, a magnesium compound separation and recovery system, an atmosphere roaster and a depolymerization crusher connected in sequence.

[0065] The nickel-cobalt separation and recovery system is a nickel-cobalt compound separation device; the magnesium compound separation and recovery system includes a magnesium compound separator and a filter system; the nickel-cobalt separation and recovery system is connected to the filter system through a magnesium compound separator; The compound separator is connected with the atmosphere roaster through a filter system; the nickel-cobalt compound separator includes a nickel-cobalt compound separator and a nickel-cobalt filter system, and the nickel-cobalt compound separator is connected with the magnesium compound separator through a nic...

Embodiment 3

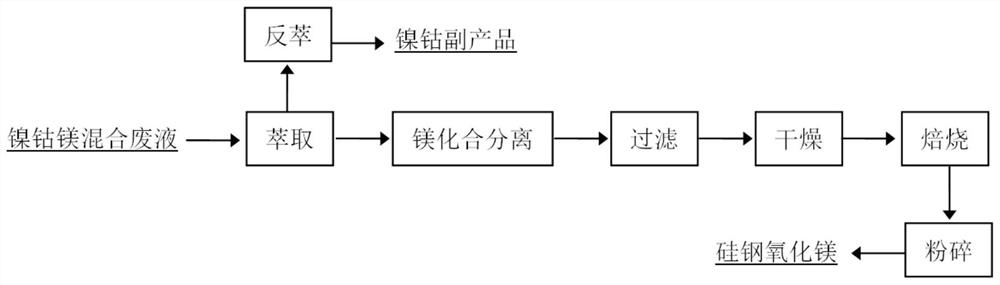

[0068] The method that present embodiment provides reclaims nickel, cobalt and co-produces magnesium oxide from nickel-cobalt-magnesium waste liquid, such as image 3 As shown, it specifically includes the following steps:

[0069] (1) Extraction and separation of nickel and cobalt: 100L mixed waste liquid (pH2 SO 4 Perform back extraction to recover nickel and cobalt to obtain a nickel-cobalt-containing solution and a magnesium-containing solution, wherein the nickel-cobalt recovery rate is greater than 96%;

[0070] (2) The magnesium-containing solution gained in step (1) is transported to the magnesium compound separation reactor, and its pH is adjusted to about 7, and the Mg ion content in the measurement solution is 22.5g / L. Based on the magnesium ion content, add 1.3 times Ammonium bicarbonate of the amount of magnesium ion substance and 3L 25% ammoniacal liquor, after stirring for 30min, the feed liquid temperature of the magnesium compound separation reactor is raised...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com