Method for synchronously removing antimony and bromine from electronic waste flame-retardant plastic and recovering plastic matrix

A technology for electronic waste and flame retardant plastics, applied in the field of resource utilization, can solve problems such as environmental pollution and resource waste, and achieve the effects of reducing environmental pollution, saving energy and reducing environmental pollution, and reducing the utilization of energy resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

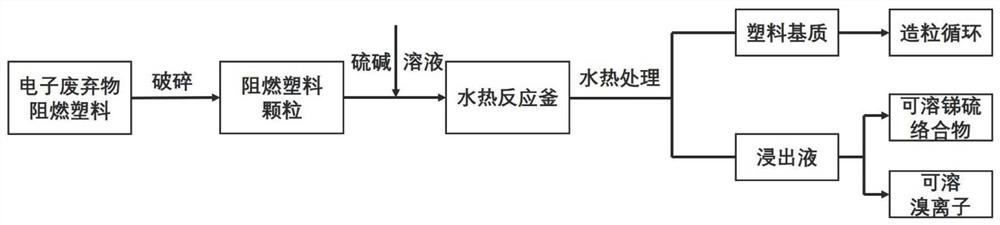

Method used

Image

Examples

Embodiment 1

[0051] Firstly, the electronic waste flame-retardant plastic HIPS is placed in a crusher for crushing, so that the particle size of the crushed plastic particles is 1-3 cm. The obtained plastic granules were collected and put into a stainless steel-lined crucible, and 100ml of sodium sulfide and sodium hydroxide mixed solution was added into the stainless steel-lined crucible, wherein the concentration of sodium sulfide was 50g / L, and the concentration of sodium hydroxide was 25g / L. Put the stainless-steel-lined crucible into the reaction kettle, open the exhaust pipe, let in nitrogen gas to exhaust the air, seal it, and place it in a heating jacket. Start the power supply of the hydrothermal reactor device, raise the internal temperature of the reactor to 220°C, and then keep the temperature constant, so that the antimony and bromine flame retardants in the flame-retardant plastic in the reactor can fully react with the solute and be leached and removed synchronously. The hol...

Embodiment 2

[0055] First, the electronic waste flame-retardant HIPS plastic is crushed in a crusher, so that the particle size of the crushed plastic particles is 4-5cm. The obtained plastic particles were collected and put into a stainless steel-lined crucible, and 100ml of sodium sulfide and sodium hydroxide mixed solution was added into the stainless steel-lined crucible, wherein the concentration of sodium sulfide was 55g / L, and the concentration of sodium hydroxide was 30g / L. Put the stainless-steel-lined crucible into the reaction kettle, open the exhaust pipe, let in nitrogen gas to exhaust the air, seal it, and place it in a heating jacket. Start the power supply of the hydrothermal reactor device, raise the internal temperature of the reactor to 200°C, and then keep the temperature constant, so that the antimony and bromine flame retardants in the flame-retardant plastic in the reactor can fully react with the solute and be leached and removed synchronously. The holding time is 2...

Embodiment 3- Embodiment 8

[0059] First, the electronic waste flame-retardant HIPS plastic is crushed in a crusher, so that the particle size of the crushed plastic particles is 1-5cm. The obtained plastic particles were collected and put into a stainless steel-lined crucible, and 100ml of a mixture of sodium sulfide and sodium hydroxide was added to the stainless-lined crucible, wherein the concentrations of sodium sulfide and sodium hydroxide were shown in Table 1. Put the stainless-steel-lined crucible into the reaction kettle, open the exhaust pipe, let in nitrogen gas to exhaust the air, seal it, and place it in a heating jacket. Start the power supply of the hydrothermal reactor device, raise the internal temperature of the reactor as shown in Table 1, and then keep the temperature constant. The antimony removal rate and bromine removal rate are shown in Table 1 below. It is difficult to achieve antimony removal rate greater than 85%, and bromine removal rate greater than 90%.

[0060] Table 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com