Collaborative resourceful treatment method and treatment system for oil-based rock debris and kitchen biogas residues

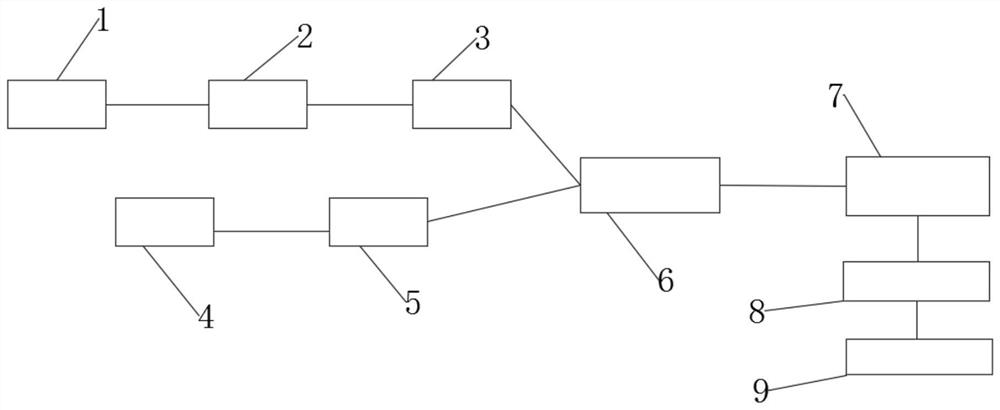

A treatment system and oil-based rock technology, which is applied in the field of oil-based cuttings and kitchen residue collaborative resource processing methods and processing systems, can solve the problems of oil-based cuttings and kitchen residues that are difficult to handle or reuse , to achieve the effect of improving the value of resource utilization, strong economic practicability, and less cumbersome operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The oil-based cuttings after removing large debris are centrifuged and then separated into solid and liquid. The obtained solid-phase oil-based cuttings have an oil content of 8%. The solid-phase residues of the oil-based cuttings are placed in a drying environment of 200 degrees Celsius for 12 hours. , after it is dried and shaped, grind it to obtain powdery solid phase residue; filter out the large debris and carry out centrifugal dehydration to obtain a slurry with a moisture content of 50%; heat the treated slurry to 60 degrees Celsius, A second centrifugation was performed to obtain a mixture of grease and solid phase residue (the mixing ratio was 2.5:1).

[0038]Mix the solid residue powder of the oil-based cuttings and the solid residue mixture uniformly in a volume ratio of 1:3, add a coagulant with a volume fraction of 2% during the mixing process, and transfer it to 200 degrees Celsius after mixing evenly. Dry in a dry environment for 12h, and then compress th...

Embodiment 2

[0040] The oil-based cuttings after removing large debris are centrifuged and then separated into solid and liquid. The obtained solid-phase oil-based cuttings have an oil content of 6%. The solid-phase residues of the oil-based cuttings are placed in a drying environment of 250 degrees Celsius for 8 hours. , after it is dried and formed, it is ground to obtain powdery solid residue; the kitchen waste after filtering out large debris is centrifugally dehydrated to obtain a slurry with a moisture content of 55%; the treated slurry is heated to 55 degrees Celsius, A second centrifugation was performed to obtain a mixture of grease and solid phase residue (the mixing ratio was 3:1).

[0041] Mix the solid residue powder of the oil-based cuttings and the solid residue mixture uniformly according to the volume ratio of 1:4. During the mixing process, add a coagulant with a volume fraction of 1%. After mixing evenly, transfer it to 230 degrees Celsius. Dry in a dry environment for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com