Method for production of ethanol or lactic acid

A technology of ethanol and lactic acid, which is applied in the direction of manufacturing tools, biofuels, wood processing appliances, etc., and can solve the problems of undisclosed preparation of ethanol and lactic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Both the ethanol preparation method and the lactic acid preparation method of the present invention use palm trunks or felled palm trunks as raw materials, and ferment the raw materials with microorganisms to prepare ethanol or lactic acid.

[0044]Palm trunks can be palm trunks with reduced fruit yields such as oil palm, sago palm, coconut or water palm, or palm trunks that have passed through more than 20 years. Palm tree trunks harvested for cultivation and planned cultivation, or young palm trunks that have to be harvested due to diseases and insect pests, as long as they are palm trunks that can collect sap.

[0045] As a method of collecting sap from a palm trunk, physical pressing, pulverization, drying and centrifugation, heating with water vapor, addition of water, extraction with an organic solvent can be used. In addition, pre-treatment with chemicals allows for easy collection of sap. It is especially preferred that the harvested palm trunk is crushed follo...

Embodiment 1

[0075] The present invention is further described in detail below through examples. In addition, the examples do not limit the scope of the present invention.

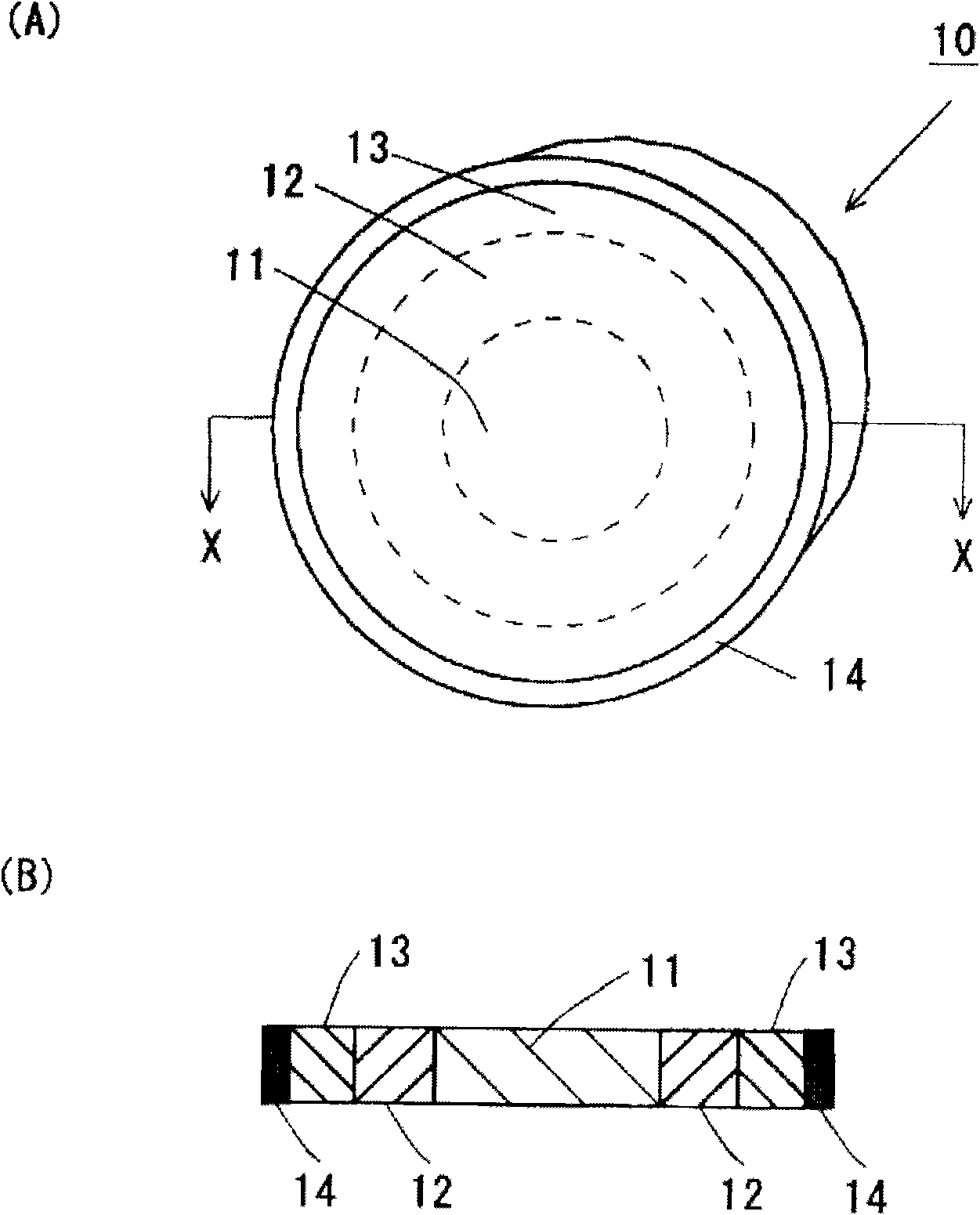

[0076] Cut the oil palm trunk with a diameter of 32 to 33 cm after harvesting into a disc shape with a thickness of 6.8 to 7.0 cm, and cut it into three equal parts from the center to the bark 14 at an interval of about 5 cm into a central area 11, a middle area 12 and an outer area 13. Except for the outermost bark 14, the outer region 13, the middle region 12, and the center region 11 were coarsely pulverized, and then pulverized with a rotary pulverizer to obtain pulverized oil palm trunks. Crushed oil palm trunks from each area were press-filtered using a glass filter to collect sap. The amount of sap collected by filtration from the part of the central area 11 is about 140cm 3 , the amount of sap collected from the part of the middle area 12 is about 80cm 3 , the amount of sap collected from the part of the ou...

Embodiment 2

[0101] Using a raw material in which sap extracted from the central region 11 of the felled oil palm trunk 10 is mixed with an enzymatic hydrolyzate of fiber, ethanol fermentation with microorganisms is performed. Among them, the enzymatic decomposition product of fiber was dried and concentrated overnight at 50° C., dissolved in the previously obtained sap containing a nitrogen source, sterilized by filter filtration, and then subjected to an ethanol fermentation test. Other conditions are identical with embodiment 1.

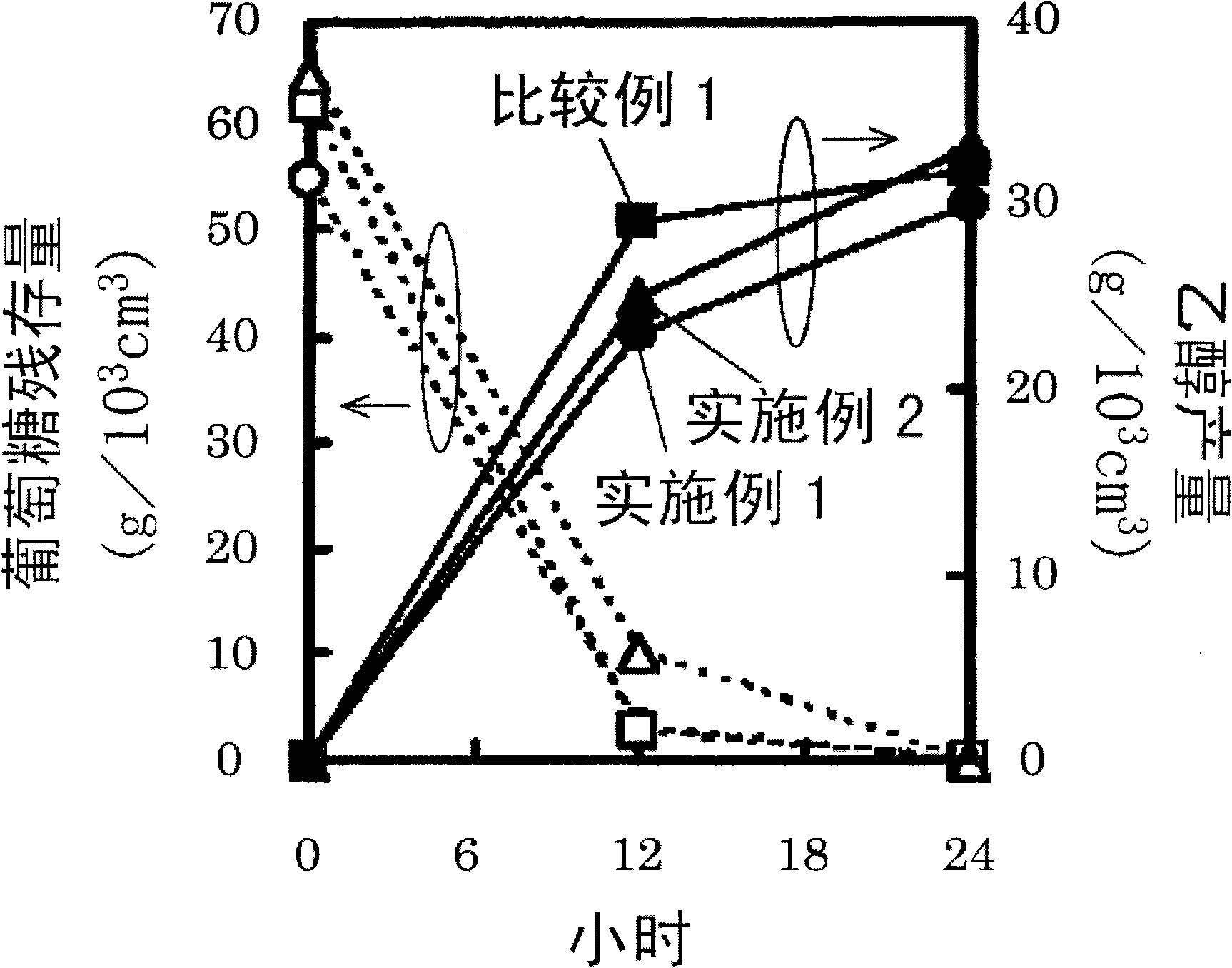

[0102] The results of Examples 1 and 2 and Comparative Example 1 will be described.

[0103] figure 2 Shown are graphs of residual glucose and ethanol production versus fermentation time for Examples 1 and 2 and Comparative Example 1. In the figure, the horizontal axis is the fermentation time (hour), and the left vertical axis is the residual amount of glucose (g / 10 3 cm 3 ), the right vertical axis is ethanol production (g / 10 3 cm 3 ). In the figure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com