Reverse flexible disassembling line for scraped vehicles

A kind of scrapped car, flexible technology, applied in the direction of vehicle scrapped recycling, motor vehicle, solid waste removal, etc., can solve the problems of low dismantling efficiency, low dismantling efficiency of scrapped car shell, environmental pollution, etc., to improve recycling and utilization. Efficiency, eliminate dioxin generation, avoid air pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

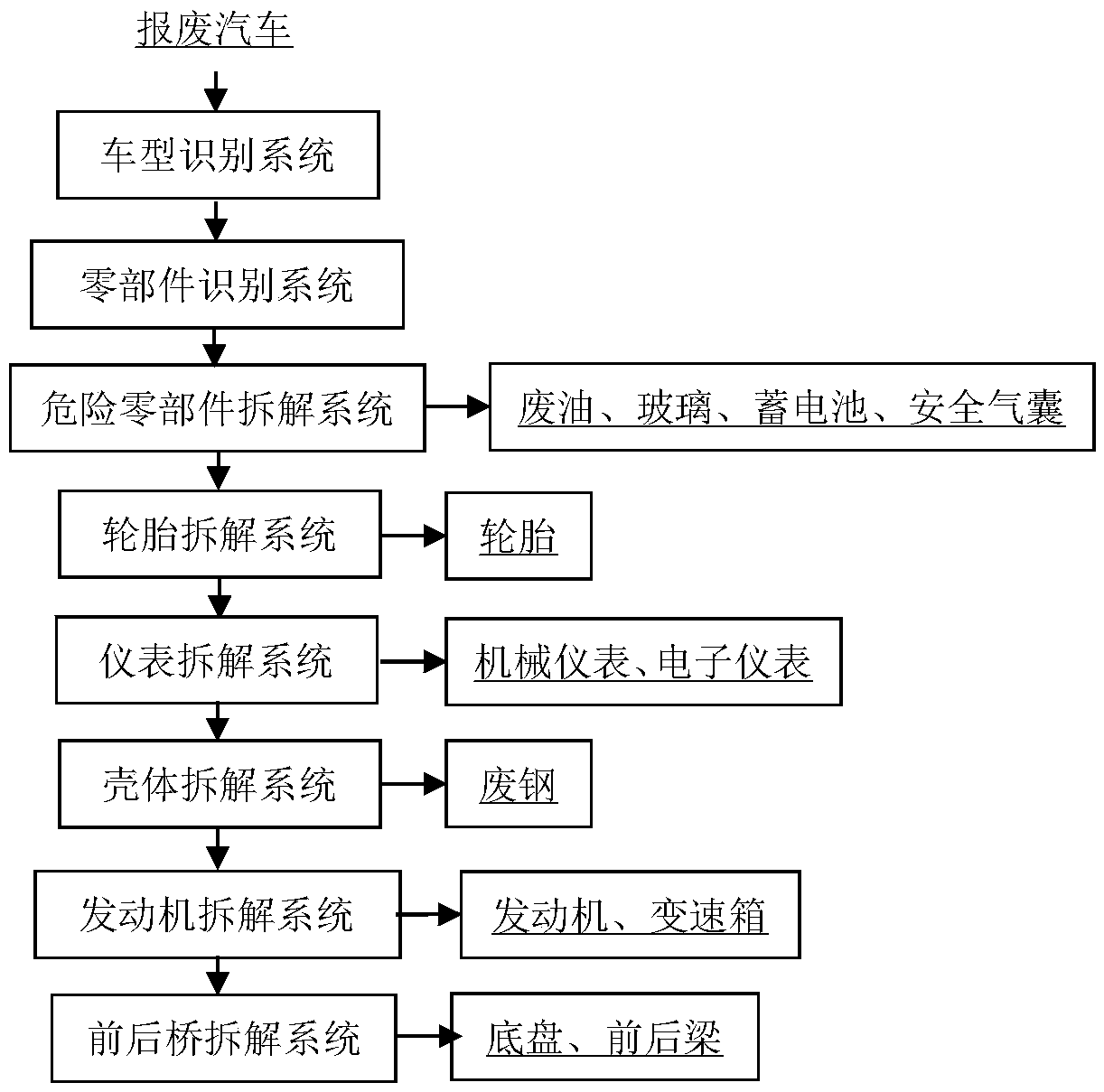

[0038] Such as figure 1As shown, the reverse flexible dismantling line for scrapped vehicles includes vehicle model identification system, parts identification system, dangerous parts dismantling system, tire dismantling system, instrument dismantling system, shell dismantling system, engine dismantling system, front and rear axle Dismantling systems, transfer systems, etc. The specific steps of the reverse flexible dismantling line for scrapped cars are as follows: First, hoist the scrapped car at the dismantling station, transfer the scrapped car to the vehicle type identification system through the elevated track trolley, and collect the appearance, logo and model plate of the scrapped car with a CCD camera and other information, after being processed by the information processor, and compared with the motor vehicle model database, when the matching degree with the data of a certain model is 96%, it can be determined as a scrapped vehicle of this model, wherein, the model i...

Embodiment 2

[0040] Such as figure 1 As shown, the reverse flexible dismantling line for scrapped vehicles includes vehicle model identification system, parts identification system, dangerous parts dismantling system, tire dismantling system, instrument dismantling system, shell dismantling system, engine dismantling system, front and rear axle Dismantling systems, transfer systems, etc. The specific steps of the reverse flexible dismantling line for scrapped cars are as follows: First, hoist the scrapped car at the dismantling station, transfer the scrapped car to the vehicle type identification system through the elevated track trolley, and collect the appearance, logo and model plate of the scrapped car with a CCD camera and other information, after being processed by the information processor, and compared with the motor vehicle model database, when the matching degree with the data of a certain vehicle model is 97%, it can be determined as a scrapped vehicle of that model. is 23ms. ...

Embodiment 3

[0042] Such as figure 1 As shown, the reverse flexible dismantling line for scrapped vehicles includes vehicle model identification system, parts identification system, dangerous parts dismantling system, tire dismantling system, instrument dismantling system, shell dismantling system, engine dismantling system, front and rear axle Dismantling systems, transfer systems, etc. The specific steps of the reverse flexible dismantling line for scrapped cars are as follows: First, hoist the scrapped car at the dismantling station, transfer the scrapped car to the vehicle type identification system through the elevated track trolley, and collect the appearance, logo and model plate of the scrapped car with a CCD camera and other information, after being processed by the information processor, and compared with the motor vehicle model database, when the matching degree with the data of a certain vehicle model is 98%, it can be determined as a scrapped vehicle of that model. is 21ms. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com