A system for recovering heavy metals from waste scr catalysts and its treatment method

A technology of SCR catalyst and heavy metal, which is applied in the field of waste SCR catalyst recovery, can solve the problems of secondary toxic waste residue, secondary pollution, low production efficiency, etc., and achieve the goal of increasing the value of resource utilization, avoiding secondary pollution, and improving the value of resource utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

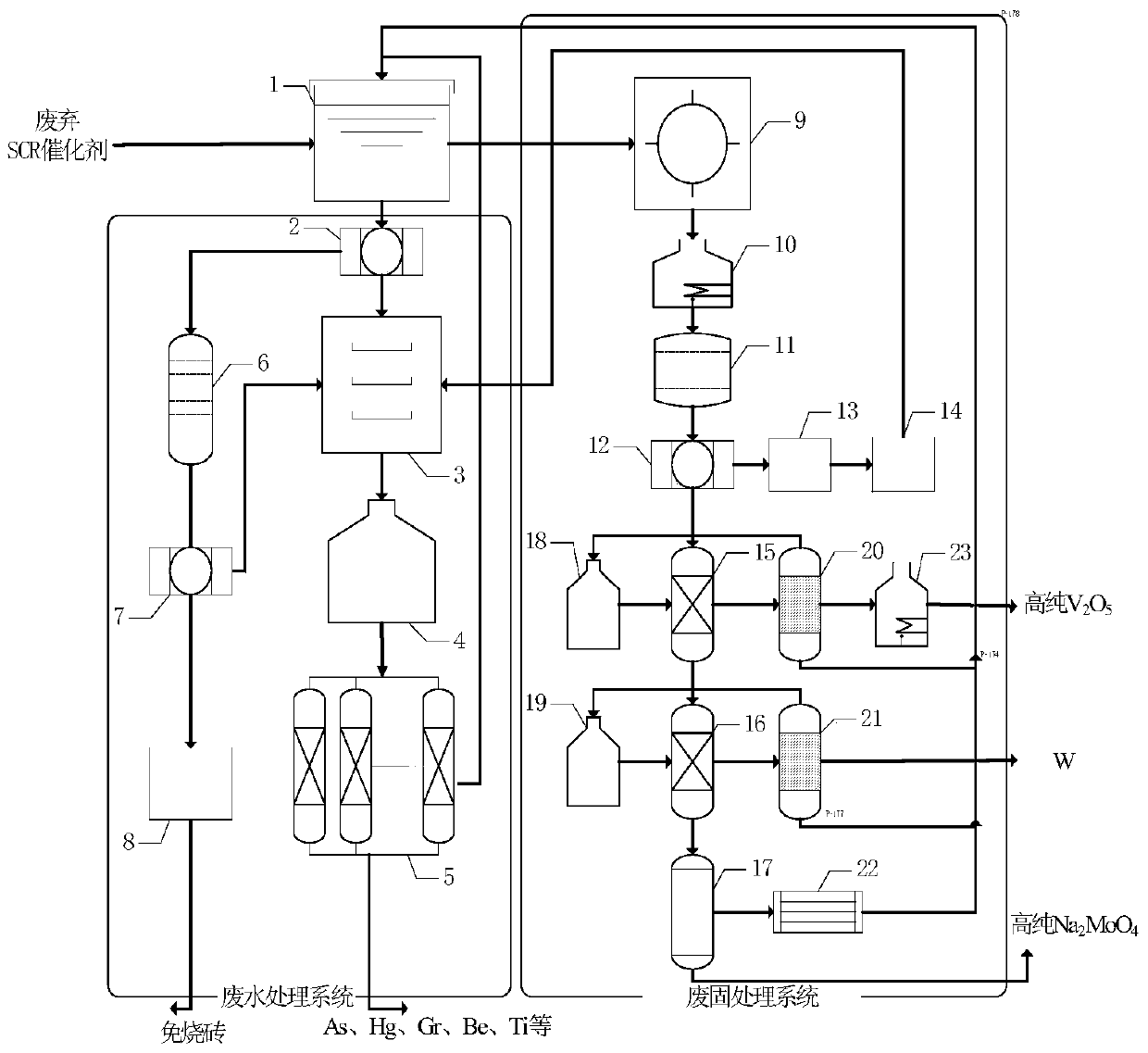

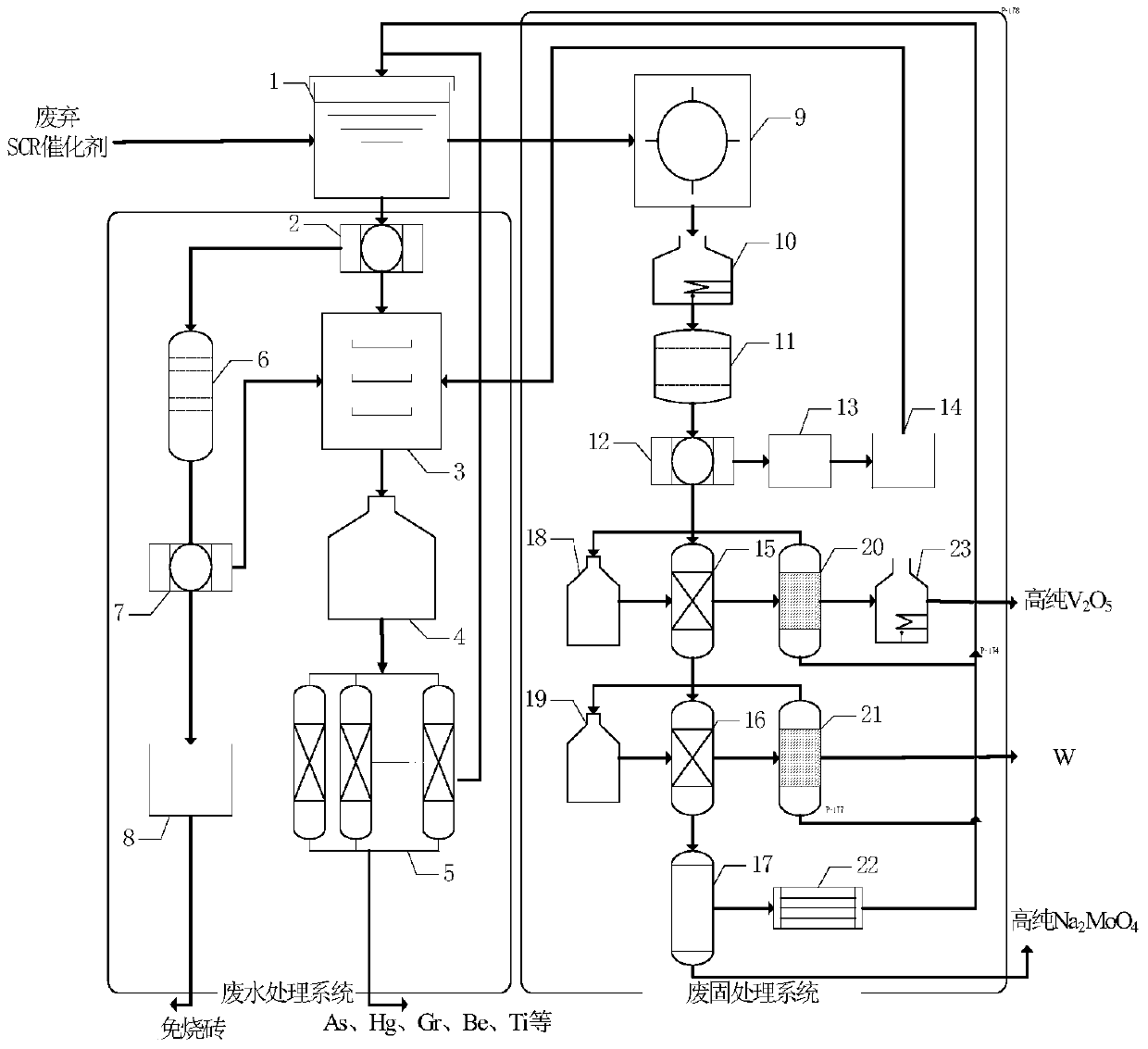

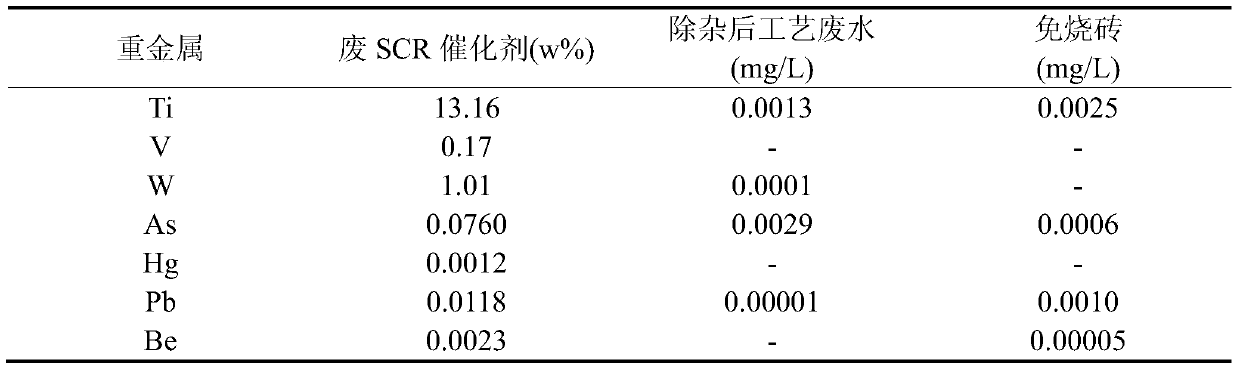

[0074] This embodiment provides a system for recovering heavy metals from waste SCR catalysts, the system includes an elution system 1, a waste water treatment system and a waste solid treatment system, wherein the liquid phase outlet of the elution system 1 is connected to the waste water treatment system The feed port of the filtering device 2 is connected, and the solid phase outlet of the elution system 1 is connected with the feed port of the crushing device 9 of the waste solid treatment system.

[0075] The wastewater treatment system includes a filter device 2, a magnetic enrichment device, a combined separator 5 and a solid phase sludge treatment system, wherein the liquid phase outlet of the filter device 2 is connected to the magnetic enrichment device and the combined separator 5 in sequence, and the filter The solid phase outlet of the device 2 is connected to the solid phase sludge treatment system, and the liquid phase outlet of the combined separator 5 is connec...

Embodiment 2

[0087] Except that the mixture of nano-scale activated carbon, nano-scale alumina and nano-scale resin adsorbent is used as the magnetic nano-adsorbent in the magnetic enrichment device 3, the combined separator 5 is a combination of an adsorption separator, an extraction separator and a precipitation separator. In addition, other device structures and device connection methods are the same as those in Example 1.

Embodiment 3

[0089] Except that the nano-scale resin adsorbent is used as the magnetic nano-adsorbent in the magnetic concentrator 3, and the combined separator 5 is a centrifugal separator, other device structures and connection methods are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com