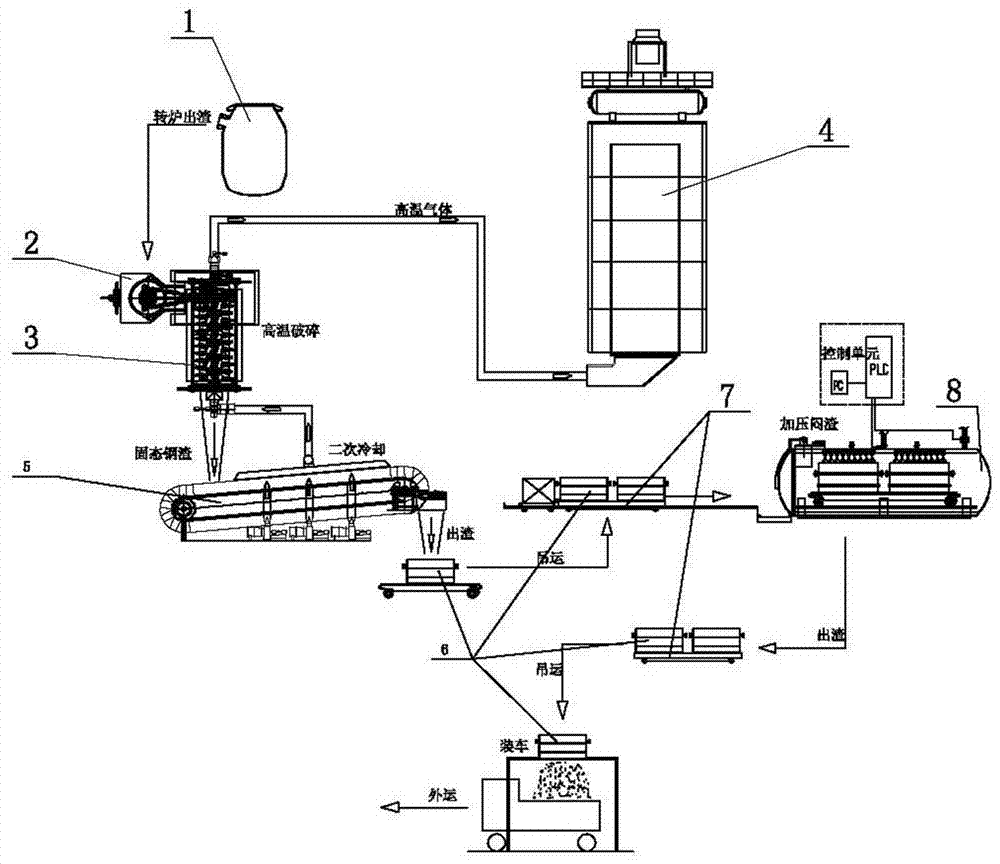

Steel slag waste heat recovery and pressurized slag disintegrating system and technology

A waste heat recovery and steel slag technology, which is applied in metal processing, recycling technology, process efficiency improvement, etc., can solve problems such as low steam quality, air pollution, and high water content in steam, so as to shorten the slag cycle and reduce equipment loss , The effect of enhancing the value of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

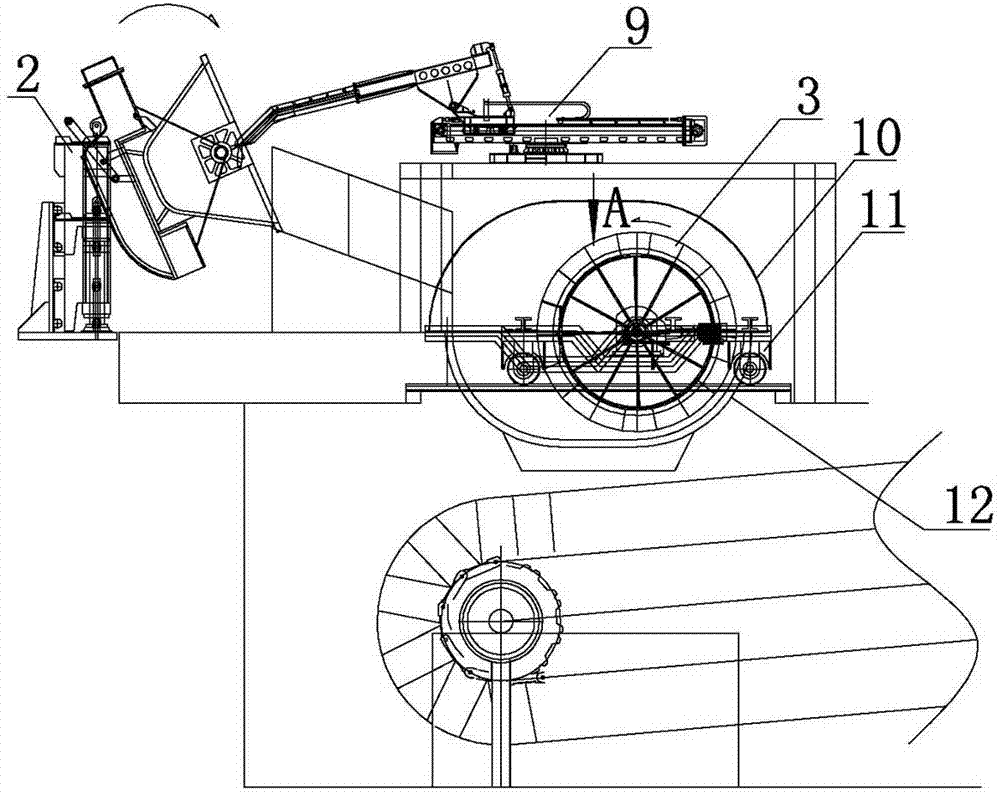

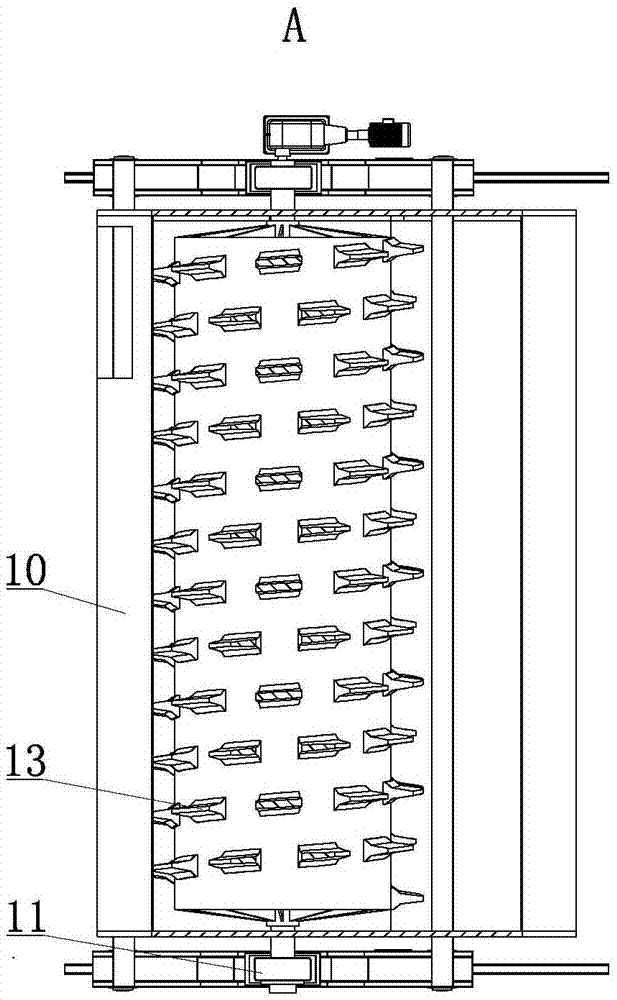

[0016] Steel slag waste heat recovery and pressurized slag system, including slag tank tilting mechanism 2, drum 3, waste heat boiler 4, belt cooler 5, slag tank 6, slag tank trolley 7, slag tank pressure still 8 and grill The slag machine 9 and the slag tank tipping mechanism 2 can tip the slag tank containing steel slag. The surface of the drum 3 is provided with roller teeth 13 arranged in a spiral shape. The lower part of the drum 3 is provided with a steel slag tank 12 . , the slag remover 9 can transport the steel slag in the overturned slag tank to the steel slag tank 12, the discharge port of the steel slag tank 12 is located above the belt cooler 5, and the belt cooler 5 and the steel slag tank 12 Gas pipelines, gas pipelines are set between the steel slag tank 12 and the waste heat boiler 4, and the first fan is installed on the belt cooler 5, and the first fan blows the outside air into the belt cooler 5 and makes the primary heat exchange with the steel slag The ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com