A kind of catalyst for producing btx aromatic hydrocarbons by utilizing organic waste and its preparation method and use, and the method for producing btx aromatic hydrocarbons

An organic waste, BTX aromatics technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. The product has no application market, and the pyrolysis gas phase product is difficult to be directly and efficiently used, so as to achieve the effect of improving the utilization value, enhancing the resource value, and the preparation method is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

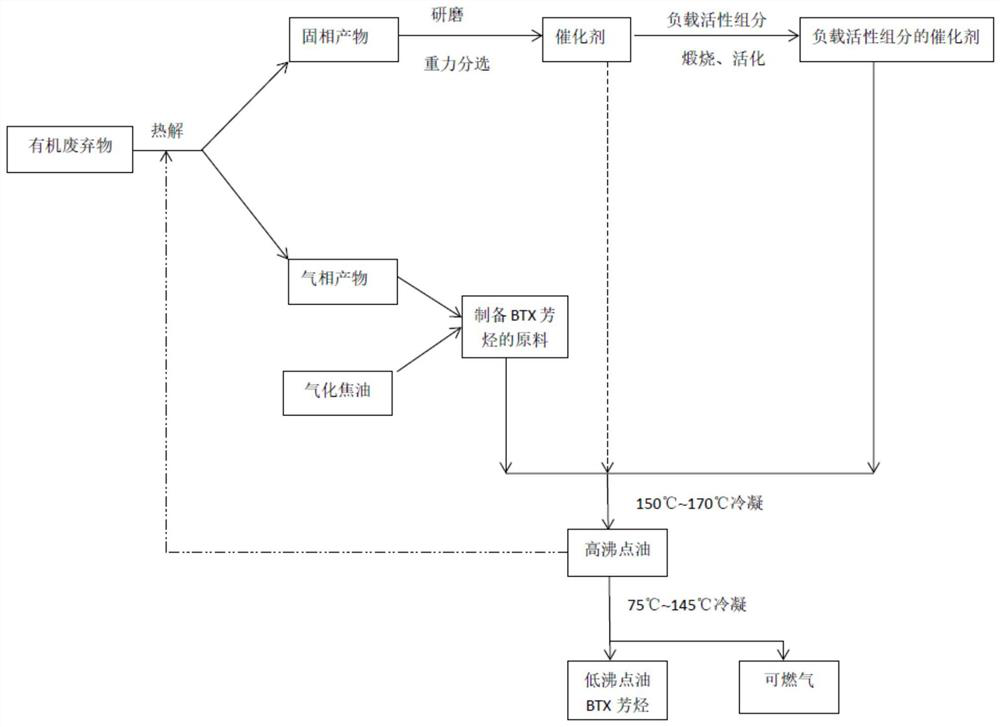

[0060] The schematic diagram of the preparation process of the BTX aromatics of the application of the present invention is as follows figure 1 . Specifically, the organic wastes are pyrolyzed to obtain solid-phase semi-coke and gas-phase product volatiles; the solid-phase semi-coke is ground to obtain carbon powder, that is, a catalyst is obtained; A catalyst loaded with active components is obtained.

[0061] The gas-phase product volatiles produced by the pyrolysis of gasified tar and / or organic waste undergo a catalytic reaction under the action of a catalyst and / or a catalyst loaded with active components, and the catalytic reaction product is first condensed at 150°C to 170°C to obtain The high boiling point oil can be used as a reaction raw material after being heated to a gaseous state or atomized; the catalytic reaction product is condensed at 70℃~140℃ for the second time to obtain a low boiling point oil BTX aromatics and combustible gas.

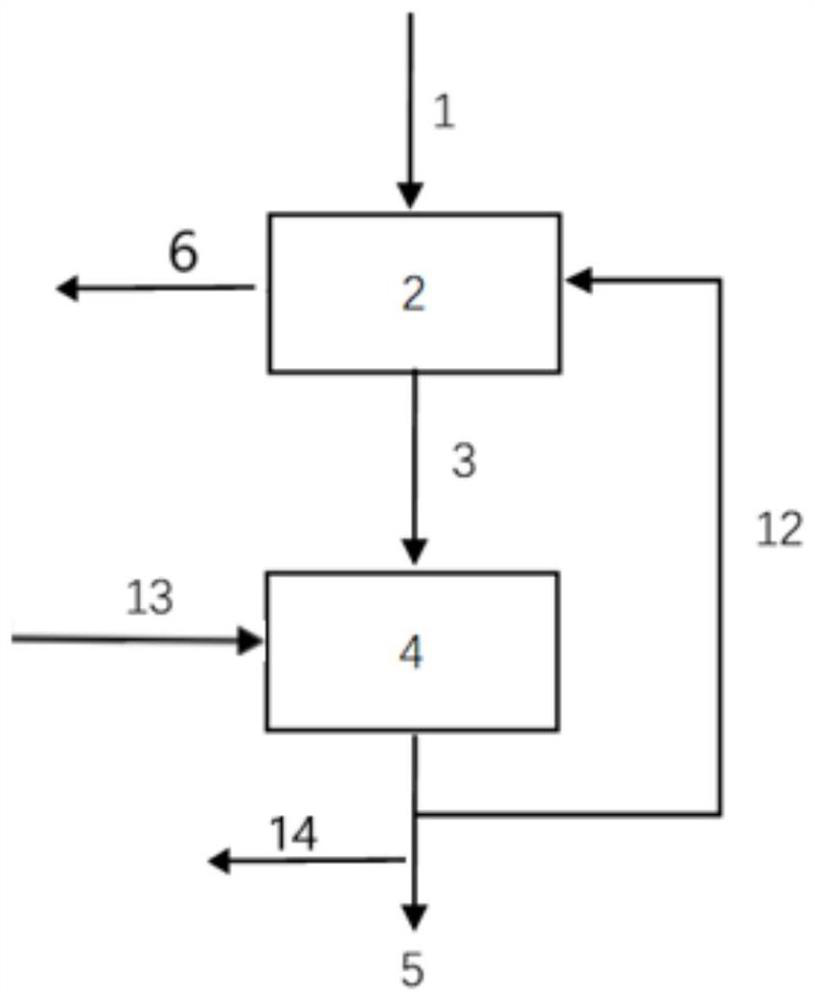

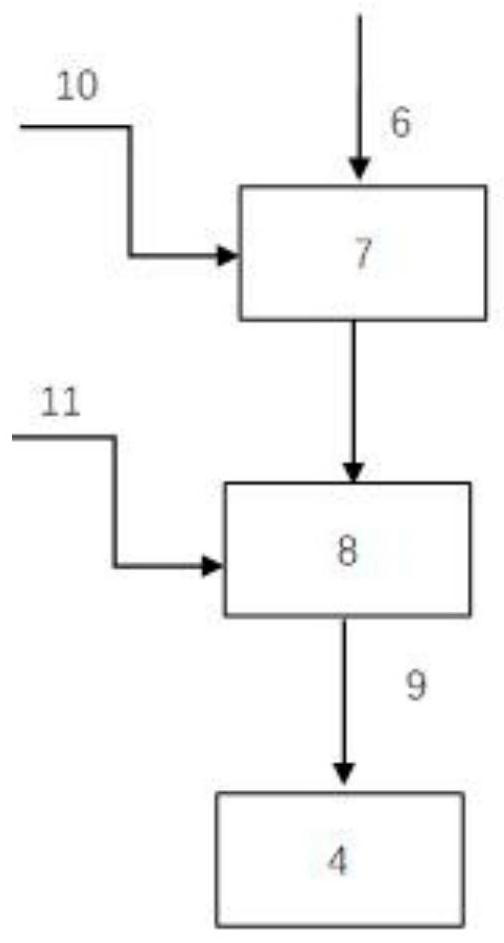

[0062] The flow chart of...

Embodiment 2

[0064] In the present embodiment, the preparation method of producing BTX aromatics is as follows:

[0065] 1) In the pyrolysis reactor, the organic wastes are pyrolyzed to obtain solid-phase product semi-coke and gas-phase product volatiles; wherein, the organic wastes are waste plastics with a calorific value of 13MJ / kg and a moisture content of 30% , the heating rate during pyrolysis is 20 °C / min, and the temperature is kept at 500 °C for 60 min.

[0066] 2) Grinding the solid-phase product semi-coke obtained in step 1), passing through a 60-mesh sieve, and adopting gravity separation to obtain carbon powder with a carbon content of 53% to obtain a catalyst.

[0067] 3) The carbon powder obtained in step 2) is immersed in a saturated solution of nickel nitrate, and dried to obtain Ni-loaded carbon powder; wherein the mass ratio of nickel nitrate and carbon powder is 1:6.5.

[0068] 4) The Ni-loaded carbon powder obtained in step 3) was calcined at 500 °C for 2 h in a nitro...

Embodiment 3

[0072] In the present embodiment, the preparation method of producing BTX aromatics is as follows:

[0073] 1) In the pyrolysis reactor, the organic wastes are pyrolyzed to obtain solid-phase product semi-coke and gas-phase product volatiles; wherein, the organic wastes are waste plastics with a calorific value of 23MJ / kg and a moisture content of 27% , the heating rate during pyrolysis was 28°C / min, and the temperature was kept at 550°C for 55 minutes.

[0074] 2) Grinding the solid-phase product semicoke obtained in step 1), passing through a 60-mesh sieve, and adopting gravity separation to obtain carbon powder with a carbon content of 65% to obtain a catalyst.

[0075] 3) The carbon powder obtained in step 2) is immersed in a mixed aqueous solution of zinc nitrate and manganese nitrate, and dried to obtain a carbon powder loaded with Zn and Mn; wherein, the mass ratio of zinc nitrate and carbon powder is 1:3.45, and the second The mass ratio of the metal Mn to the first m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com