Coal-based graphene quantum dot and preparation method thereof

A graphene quantum dot, coal-based technology, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of expensive raw materials, complicated process, high production cost, etc., to shorten the reaction time, reduce the severity, reduce the The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

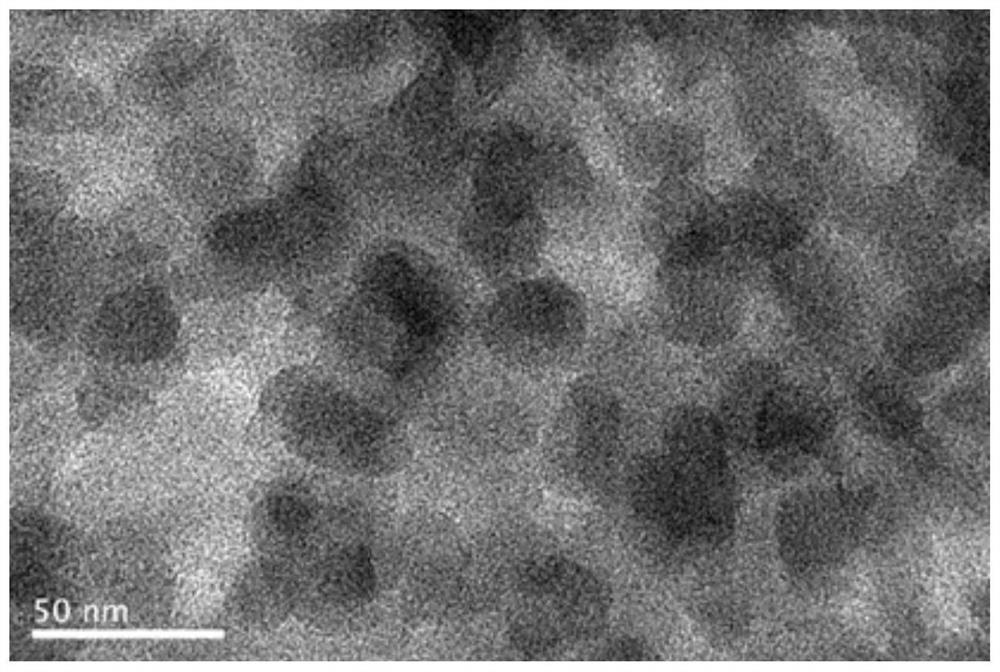

[0050] Weigh bituminous coal (the average particle size is 70-80 μm, and the ash content of the bituminous coal after deashing is 0.61% by weight) and nitric acid (concentration is 68% by weight) by acid washing and deashing with a weight ratio of 1:8, followed by Put it into the sample tube, react at 25°C for 1 hour, put the sample tube into the microwave digestion instrument, react at the infrared limit temperature of 125°C for 30 minutes, and then carry out microwave digestion to remove the acid for 20 minutes to obtain the solid oxidation product. Dissolve the solid oxidation product in water, after filtration, adjust the pH value of the filtrate with ammonia solution to 7, obtain the coal-based graphene quantum dots after the obtained solution is freeze-dried, and test the particle size range of the coal-based graphene quantum dots by TEM 5-25nm, see figure 1 .

Embodiment 2

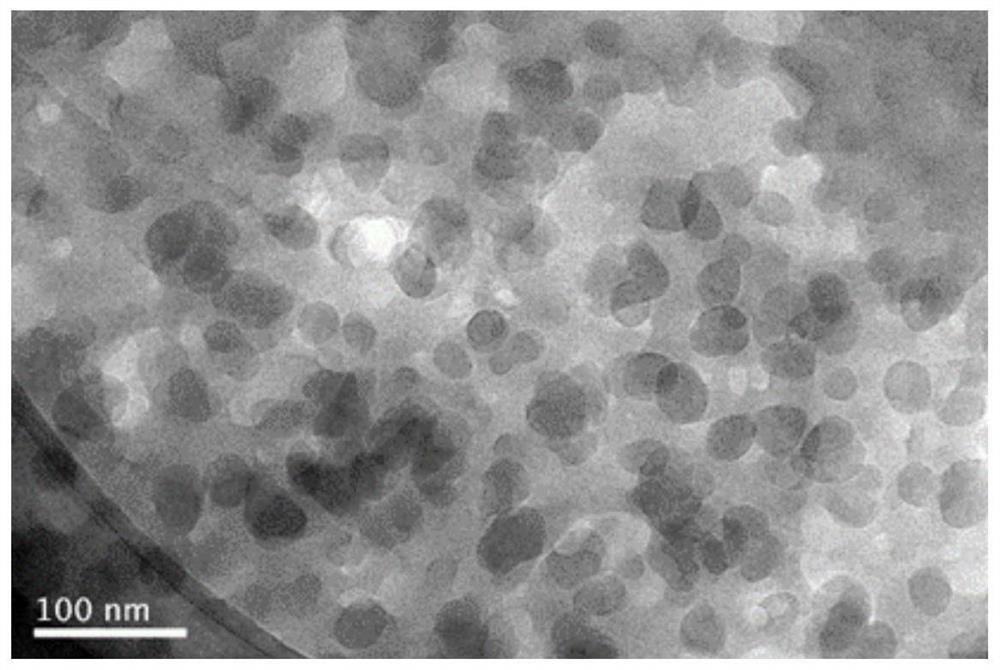

[0052] Weigh anthracite (average particle size 70-80 μm, deashed by acid washing, the ash content of anthracite after deashing is 0.91% by weight) and nitric acid with a weight ratio of 1:8, add them to the sample tube in turn, and heat at 25°C After reacting for 1 hour, put the sample tube into a microwave digestion apparatus, react at an infrared limit temperature of 125°C for 30 minutes, and then carry out microwave digestion to remove acid for 20 minutes to obtain a solid oxidation product. The solid oxidation product is dissolved in water, after filtration, the pH of the filtrate is adjusted to 7 with ammonia solution, and the obtained solution is freeze-dried to obtain coal-based graphene quantum dots. The particle size range of coal-based graphene quantum dots tested by TEM is 8-28nm, see figure 2 .

Embodiment 3

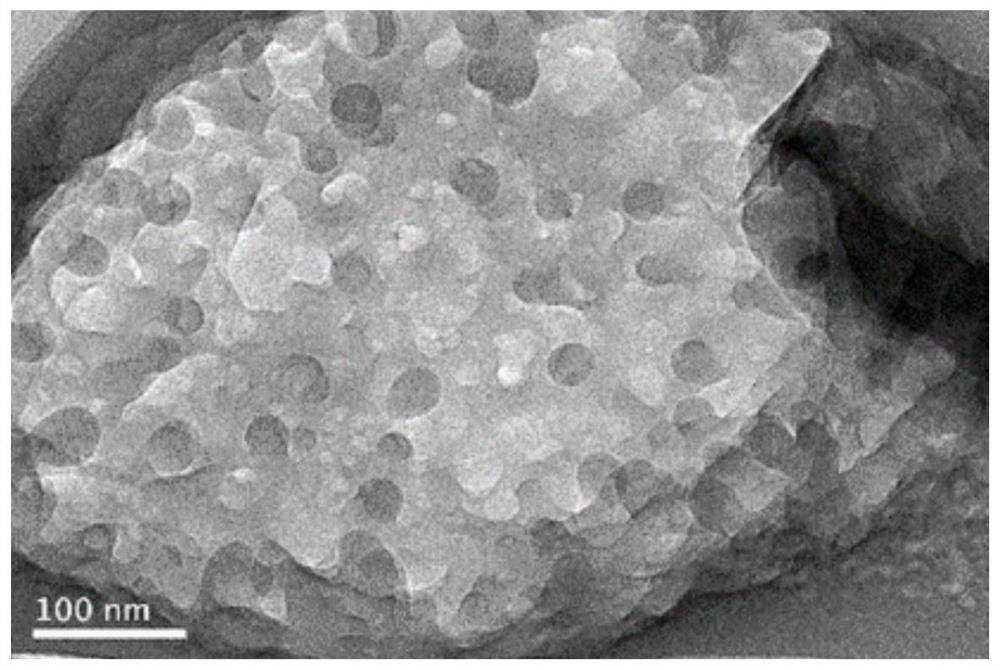

[0054] Weigh lignite (average particle size is 60-90 μm, deashed by acid washing, the ash content of lignite after deashing is 0.40% by weight) and nitric acid with a weight ratio of 1:12, add to the sample tube in turn, and react at room temperature After 2 hours, put the sample tube into a microwave digestion apparatus, react at an infrared limit temperature of 150°C for 30 minutes, and then perform microwave digestion to remove acid for 30 minutes to obtain a solid oxidation product. Dissolve the solid oxidation product in water, after filtration, adjust the pH value of the filtrate with ammonia solution to 7, obtain the coal-based graphene quantum dots after the obtained solution is freeze-dried, and test the particle size range of the coal-based graphene quantum dots by TEM 10-35nm, see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com