Vapor supply device

A technology for supplying devices and steam generating devices, applied to steam generating devices, heating devices, steam generation, etc., to achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

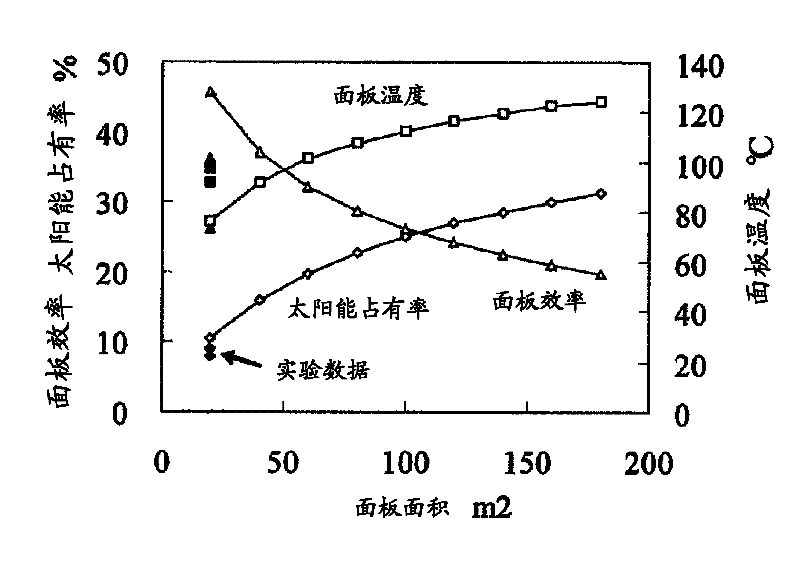

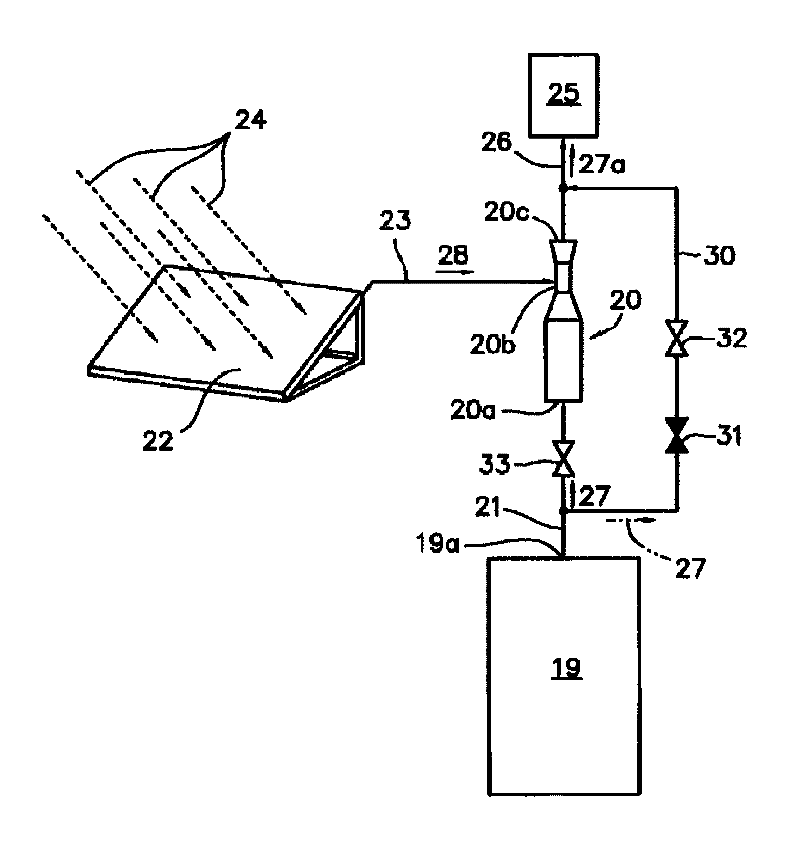

[0101] As an embodiment of the present invention, in Figure 4 said in figure 1 The result of the actual operation of the steam supply device of the embodiment shown. As an example, in the steam supply device for operation, a boiler that burns fossil fuels and generates steam is used as the high-pressure steam generating boiler 19 . This boiler has the capability of generating steam at 180°C and 850kPa. In the solar heat collector 22, a solar heat collector in the form of a heat collecting panel using sunlight is employed. The solar energy 24 is collected by the solar heat collecting panel, and the water inside is heated up. Therefore, in the steam supply device used in the examples, the temperature of the water inside can be detected by measuring the temperature of the solar heat collecting panel.

[0102] exist Figure 4 In , the horizontal axis represents the elapsed time. The elapsed time is displayed in seconds, Figure 4 The indicated operation results represent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com